What is the effect of UV monomer on UV-curable oxygen blocking?

1.2 Sample preparation and testing

The monomer and initiator were weighed accurately, where the monomer was not purified, and mixed uniformly with a magnetic stirrer. UV-DSC was used to perform UV curing experiments under static air atmosphere and nitrogen atmosphere, and the samples were taken in equal amounts each time so that the thickness of the samples in the crucible was the same. The UV-DSC program was set to keep the sample temperature constant for 2 min, then the light source was automatically turned on by the program, and the UV light (wavelength range 325-400 nm) was introduced into the DSC cell by the glass fiber to illuminate the sample crucible and the reference crucible, and the DSC measured the heat flow value of the sample photocuring process. The light intensity was measured as 48.27 mW-cm-2. The light intensity was determined by spreading carbon black on the bottom of the sample crucible, and the energy absorbed by the light was measured by UV-DSC and divided by the crucible bottom area to obtain the light intensity.

2 Results and discussion

2.1 Data processing

The light curing rate was calculated as

The light curing rate R=dC/dt=(dH/dt)/Hmax, where dH/dt is the heat flow value on the curve of enthalpy versus time of the light curing process measured by UV-DSC; Hmax is the total heat of polymerization of the sample at 200 s of light exposure, obtained by integrating the light curing exothermic peak. The time corresponding to the maximum curing rate of the light curing process is tmax. Free radical polymerization will occur automatically accelerated phenomenon, the light curing rate curve to time derivative, the maximum value of the curve corresponding to the time recorded as tamax, this time can be considered as the fastest growing time of light curing rate, at this time the system oxygen blocking and cage effect and other factors on the consumption of primary radicals to a minimum. The free radical initiating monomer begins to polymerize rapidly.

Calculation of the initiator content (molar fraction) α within the sample:

Where n initiator is the molar amount of initiator in the system, f is the functional degree of monomer, and n monomer is the molar amount of monomer in the system. Figure 1 shows the molecular structure of the initiator Irgacure-184, which is a cleavage type, and the “2” in the formula (1) means that one molecule of the initiator can theoretically be decomposed into two molecules of radicals by light exposure.

The structural formula of Irgacure-184

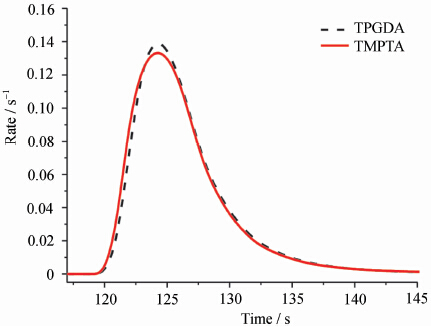

Figure 2 shows the rate curves of different monomer light curing at 4% initiator content (mass fraction). As can be seen from the figure, for different monomers, there are differences in the curing rate in the pre-curing period, and this difference is also expressed in time, which indicates that different monomer UV curing in time differences in speed. The time tamax when the light curing rate of the monomer grows fastest and the time tmax corresponding to the maximum light curing rate are compared with the variation curve of the initiator content, and the results are shown in Figure 3.

UV-curing rate curves of different monomers with 4% initiator

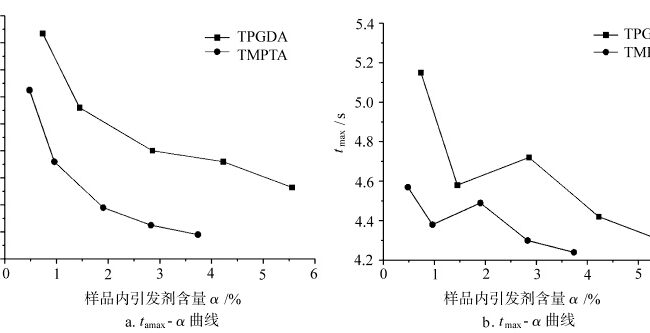

The relationship of tamax and tmax with initiator contents in curing process in air of different monomers

Figure 3 shows the curves of tmax and tamax for light curing of different monomers under air as a function of the initiator content α in the sample. In the early stage of curing, when oxygen is present, part of the reactive radicals generated by the photoinitiator due to light are consumed by the oxygen dissolved in the sample, and the other part initiates monomer polymerization. The oxygen blocking effect consumes the radicals generated by the decomposition of the initiator and the monomer radicals, thus affecting the magnitude of tamax and tmax of light curing, which in turn reflects the sensitivity of light curing to oxygen and initiator content. As seen in Fig. 3a, the tamax of each monomer light curing decreases with the increase of initiator content in a certain pattern. In Fig. 3b, the tmax of each monomer light curing shows a certain fluctuation with the increase of initiator content. This is because when the curing reaction rate reaches its maximum, the system has reached a high curing degree, and the molecular chain segments are gradually frozen due to the glassy effect, and the sensitivity of the tmax of the light-curing reaction to the initiator content is reduced at this time. While tamax in the early stage of light curing, when the system is not high degree of curing, light curing reaction is more sensitive to the content of the initiator in the system. Therefore, in comparison, tamax better reflects the sensitivity of light curing to initiator content.

2.2 Effect of atmosphere on the light-curing tamax of different monomers

In air atmosphere, the tamax of the material photocured should be different compared to that in nitrogen atmosphere due to the effect of oxygen blocking. UV-DSC tests were carried out on monomer TMPTA under air and nitrogen atmosphere when lower initiator content was added, and the results are listed in Table 1.

| tamaxtamax of TMPTA UV-curing with low initiator content in air or N2 | ||

| Content of initiator in the sample/% | tamax/s | |

| air | N2 | |

| 0.48 | 2.65 | 2.18 |

| 0.96 | 2.12 | 1.92 |

tamax of TMPTA UV-curing with low initiator content in air or N2

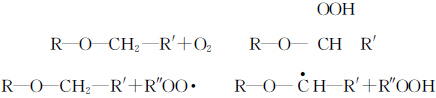

Table 1 shows the comparison of the tamax of TMPTA photocured under air and nitrogen respectively with the addition of lower levels of initiator. From the above table, it can be seen that the tamax of light curing under air is larger than that under nitrogen when the initiator content is equal, indicating that light curing under air is affected by oxygen blocking. It is generally believed that the oxygen dissolved in the raw material as well as on the surface undergoes the following reactions during the light curing process.

The generated peroxide radicals ROO- are very stable and have no ability to initiate polymerization reactions. Oxygen not only scavenges the radicals generated by the initiator during the light curing process, but also terminates the monomer radicals.

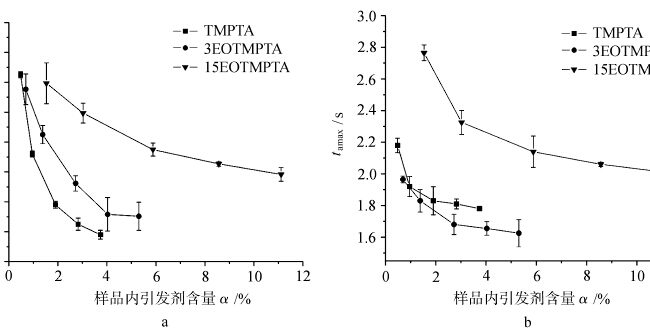

The sensitivity of photocuring to oxygen-blocking polymerization varies for different monomers and is related to factors such as monomer functionalities, double bond activity, and structure [13]. In order to investigate the effect of monomer structure on oxygen-blocking aggregation, two different EO-ized TMPTAs were selected for UV-DSC experiments under air and nitrogen conditions, respectively. These homologous monomers all have similar structures, except for the number of EO groups, which avoids complicating the problem by choosing some other monomers with widely differing structures [13].

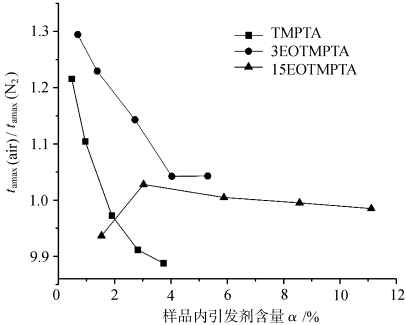

Figure 4 shows the variation of tamax with the initiator content within the sample for the light curing of TMPTA monomers with different EOizations under air and nitrogen. As seen from the figure, the tamax of each monomer photocured under air and nitrogen decreases with the increase of initiator content. The variation of the light-cured tamax of each monomer under air and nitrogen varies with the amount of EO in the monomer. This shows that the amount of EO in the monomer has an effect on the tamax of light curing. For the same monomer, the difference in the light-cured tamax under air and nitrogen is related to the oxygen barrier when other conditions are the same.

Figure 5 shows the curves of the ratio of tamax of each monomer photocured under different atmospheres with the variation of initiator content α. tamax(air)/tamax(N2) indicates the difference of tamax of monomer photocured under air and nitrogen, thus reflecting the magnitude of oxygen blocking of each monomer photocured, the larger the value, the greater the oxygen blocking effect. As seen in Figure 5, the tamax(air)/tamax(N2) ratios of monomer TMPTA and monomer 3EOTMPTA were larger when the initiator content was small and decreased with increasing initiator content. This indicates that the monomeric TMPTA and monomeric 3EOTMPTA are subject to more significant oxygen blocking effect when the initiator content is small. When the amount of EO in the monomer reaches 15, the tamax(air)/tamax(N2) ratio of the monomer is close to 1, i.e., there is little difference in the tamax of light curing under either air or nitrogen conditions, which indicates that the increase in the amount of EO in the monomer is beneficial to reduce the oxygen-blocking polymerization of UV curing, which may be related to the active hydrogen in the EO structure.The ether-like structure in the EO moiety The α-H on the -O-CH2- is easily substituted by oxygen and the following reactions occur.

The relationship of tamax(air)/tamax(N2) with initator contents in curing process of different ethoxylated TMPTA.

α-H on the one hand can consume part of the oxygen in the system, on the other hand, it can terminate the peroxide radical ROO- generated by the radical and oxygen, thus reducing the consumption of reactive radicals and redirecting the initiating activity to the chain segment with initiating activity, thus reducing the oxygen blocking of the light curing process .

2.3 Influence of the amount of α-H in monomers on the light-curing oxygen blocking aggregation

To investigate the relationship between oxygen blocking and the amount of α-H in the monomeric EO groups, the tamax-α curves in Figure 4 were linearly fitted to different equations, and it was found that the highest correlation coefficient was obtained by linearly fitting the equation lnt=a+b/α0.5. The slopes b obtained from the fits and the correlation coefficients R are listed in Table 2.

| The value of b and R by linear fit 1/α0.5 and lnt | ||||

| Monomer | air | N2 | ||

| b | R | b | R | |

| TMPTA | 0.056 | 0.99894 | 0.0213 | 0.95494 |

| EO3TMPTA | 0.0554 | 0.95877 | 0.0257 | 0.98564 |

| 15EOTMPTA | 0.0531 | 0.96578 | 0.062 | 0.98944 |

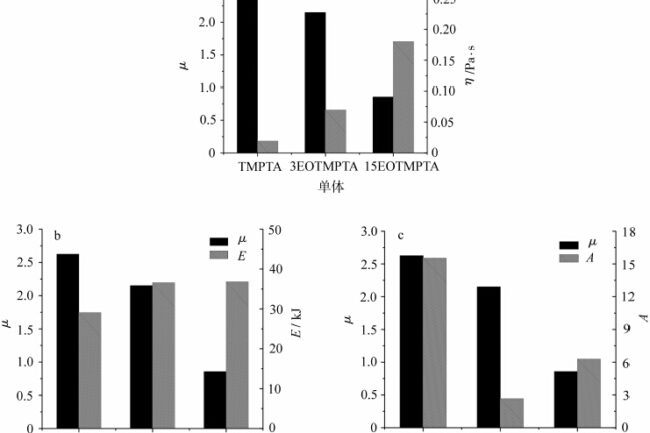

Comparing the μ values corresponding to different monomers in Figure 6, μ has a maximum value when the monomer is TMPTA, i.e., the oxygen-blocking effect is greatest when the monomer TMPTA is UV-cured. As the amount of EO in the monomer increases, the amount of α-H in the monomer increases and the μ value decreases, indicating that the oxygen barrier is related to the amount of α-H in the monomer, which traps the oxygen and peroxide radicals in the system and alleviates the oxygen barrier. Viscosity is a property related to the molecular structure, which involves the flow properties of the monomer, so it is necessary to further discuss the effect of monomer flow properties on oxygen barrier polymerization.

2.4 Influence of the flow properties of monomers on oxygen barrier aggregation

The flow properties of the system are related to the structure of the molecule. Generally, the more flexible the molecular chain is, the lower the rotational barrier within the chain, the shorter the chain segment as a mobile unit, and the lower the activation energy of the flexible molecular chain, the better the mobility. The larger the molecular weight, the greater the internal frictional resistance to molecular motion and the poor mobility [19]. Therefore, the introduction of EO groups in TMPTA monomer will change the flow properties of the system. Using a rheometer with a constant shear rate of 19.1 /min and a temperature increase rate of 2 °C/min, the viscosity curves of each monomer were measured with temperature. The viscosity-temperature curves of each monomer were fitted to the Arrhenius equation, and the calculated flow activation energy E, the prefactor A and the monomer viscosity η at 25 ℃ were listed in Table 3.

| The value of viscosity η(25 ℃),flow-activation energy E, and pre-exponential factor A of monomers | |||

| Monomer | η/Pa·s(25℃) | A/10-8 | E/J |

| TMPTA | 0.01934 | 15.53 | 29079.88 |

| 3EOTMPTA | 0.06948 | 2.65 | 36600.47 |

| 15EOTMPTA | 0.18016 | 6.28 | 36821.87 |

Among them, the flow activation energy E is related to the molecular structure and is influenced by the stiffness and flexibility of the molecular chain, the size and polarity of the side groups, etc. The index front factor A is a constant related to the molecular weight. In order to investigate the relationship between the flow properties of monomers and the oxygen barrier, the μ values of different monomers were correlated with the corresponding viscosities η, the flow activation energy E and the prefactor A, as shown in Figure 7.

Figure 7 represents the comparison of μ values of different monomers in relation to the flow activation energy E, finger front factor A, and viscosity η, respectively. As seen in Fig. 7a, the μ value tends to decrease as the number of EO in the monomer increases and the viscosity of the monomer increases. The size of oxygen blocking aggregation is closely related to the concentration of oxygen, and the larger the concentration of oxygen, the more obvious the oxygen blocking is [7]. In the interior of the light-curing system, the amount of dissolved oxygen is certain, and the rate of quenching and scavenging of free radicals by oxygen in the light-curing process is extremely fast, and the consumed oxygen is mainly replenished by the diffusion of oxygen from the air to the interior of the system continuously, which will certainly involve the ability of oxygen movement in the system, and the ability of oxygen movement in the system is related to the viscosity of the system. When the viscosity of the system is low, the oxygen in the air is easier to diffuse to the inside of the system, showing a larger oxygen blocking effect, so the μ value of the monomer TMPTA is higher and is significantly blocked by oxygen. When the viscosity of the system increases, the oxygen movement ability in the system decreases and it is too late to replenish the oxygen consumed by scavenging free radicals, and the oxygen blocking decreases. As can be seen from the figure, when the amount of EO in the monomer increases to 15, the monomer viscosity continues to increase and the μ value tends to 1, i.e., the difference between light curing under air and nitrogen is not significant.

Then compare the flow activation energy and finger front factor of the monomer with the μ value. As seen in Figure 7b, the flow activation energy of the monomer increases from TMPTA to 3EOTMPTA with the introduction of EO groups in the monomer. When the amount of EO in the monomer was increased from 3 to 15, the flow activation energy was basically unchanged, which indicates that increasing the amount of EO in the monomer has basically no effect on the flow activation energy. This is because although the number of EO in the monomer increases, the number of kinematic units does not change, which shows that for the EO-ized TMPTA monomer, the effect of the flow activation energy on the oxygen barrier is not significant. As seen in Fig. 7c, the finger prefactor A changes greatly from TMPTA to 3EOTMPTA, which may be related to the presence or absence of EO groups. With the increase in the number of EO in the monomer, the prefactor A increases, which is due to the increase in the number of EO in the monomer leading to the increase in the molecular weight of the monomer. It can be shown that for EO-ized TMPTA monomers, the increase in the number of EOs in the molecule leads to an increase in the molecular weight, which leads to an increase in the viscosity of the monomer and thus reduces the oxygen barrier. For polymeric materials, the viscosity of the system can generally be increased by increasing the rigidity of the molecular chain, increasing the polarity of the side groups, increasing the molecular weight, etc.. It can be speculated that the adverse effects of light-curing oxygen blocking can be reduced by suitable formulation composition, such as introducing structures containing active hydrogen, increasing the proportion of rigid molecules, and increasing the molecular weight.

3 Conclusion

(1) Increasing the number of EO groups in the monomer molecule can reduce the oxygen blocking aggregation during the light curing process. This is related to the trapping of oxygen and peroxide radicals by the α-H in this group and the increase of system viscosity.

(2) For several EO-ized TMPTAs selected for this study, the flow activation energy of the monomer has little effect on the oxygen blocking aggregation. The increase in the amount of EO in the monomer leads to an increase in its molecular weight, which leads to an increase in the viscosity of the monomer, which in turn has an effect on the oxygen barrier aggregation.

UV Monomer Same series products

| Polythiol/Polymercaptan | ||

| DMES Monomer | Bis(2-mercaptoethyl) sulfide | 3570-55-6 |

| DMPT Monomer | THIOCURE DMPT | 131538-00-6 |

| PETMP Monomer | 7575-23-7 | |

| PM839 Monomer | Polyoxy(methyl-1,2-ethanediyl) | 72244-98-5 |

| Monofunctional Monomer | ||

| HEMA Monomer | 2-hydroxyethyl methacrylate | 868-77-9 |

| HPMA Monomer | 2-Hydroxypropyl methacrylate | 27813-02-1 |

| THFA Monomer | Tetrahydrofurfuryl acrylate | 2399-48-6 |

| HDCPA Monomer | Hydrogenated dicyclopentenyl acrylate | 79637-74-4 |

| DCPMA Monomer | Dihydrodicyclopentadienyl methacrylate | 30798-39-1 |

| DCPA Monomer | Dihydrodicyclopentadienyl Acrylate | 12542-30-2 |

| DCPEMA Monomer | Dicyclopentenyloxyethyl Methacrylate | 68586-19-6 |

| DCPEOA Monomer | Dicyclopentenyloxyethyl Acrylate | 65983-31-5 |

| NP-4EA Monomer | (4) ethoxylated nonylphenol | 50974-47-5 |

| LA Monomer | Lauryl acrylate / Dodecyl acrylate | 2156-97-0 |

| THFMA Monomer | Tetrahydrofurfuryl methacrylate | 2455-24-5 |

| PHEA Monomer | 2-PHENOXYETHYL ACRYLATE | 48145-04-6 |

| LMA Monomer | Lauryl methacrylate | 142-90-5 |

| IDA Monomer | Isodecyl acrylate | 1330-61-6 |

| IBOMA Monomer | Isobornyl methacrylate | 7534-94-3 |

| IBOA Monomer | Isobornyl acrylate | 5888-33-5 |

| EOEOEA Monomer | 2-(2-Ethoxyethoxy)ethyl acrylate | 7328-17-8 |

| Multifunctional monomer | ||

| DPHA Monomer | 29570-58-9 | |

| DI-TMPTA Monomer | DI(TRIMETHYLOLPROPANE) TETRAACRYLATE | 94108-97-1 |

| Acrylamide monomer | ||

| ACMO Monomer | 4-acryloylmorpholine | 5117-12-4 |

| Di-functional Monomer | ||

| PEGDMA Monomer | Poly(ethylene glycol) dimethacrylate | 25852-47-5 |

| TPGDA Monomer | Tripropylene glycol diacrylate | 42978-66-5 |

| TEGDMA Monomer | Triethylene glycol dimethacrylate | 109-16-0 |

| PO2-NPGDA Monomer | Propoxylate neopentylene glycol diacrylate | 84170-74-1 |

| PEGDA Monomer | Polyethylene Glycol Diacrylate | 26570-48-9 |

| PDDA Monomer | Phthalate diethylene glycol diacrylate | |

| NPGDA Monomer | Neopentyl glycol diacrylate | 2223-82-7 |

| HDDA Monomer | Hexamethylene Diacrylate | 13048-33-4 |

| EO4-BPADA Monomer | ETHOXYLATED (4) BISPHENOL A DIACRYLATE | 64401-02-1 |

| EO10-BPADA Monomer | ETHOXYLATED (10) BISPHENOL A DIACRYLATE | 64401-02-1 |

| EGDMA Monomer | Ethylene glycol dimethacrylate | 97-90-5 |

| DPGDA Monomer | Dipropylene Glycol Dienoate | 57472-68-1 |

| Bis-GMA Monomer | Bisphenol A Glycidyl Methacrylate | 1565-94-2 |

| Trifunctional Monomer | ||

| TMPTMA Monomer | Trimethylolpropane trimethacrylate | 3290-92-4 |

| TMPTA Monomer | Trimethylolpropane triacrylate | 15625-89-5 |

| PETA Monomer | 3524-68-3 | |

| GPTA ( G3POTA ) Monomer | GLYCERYL PROPOXY TRIACRYLATE | 52408-84-1 |

| EO3-TMPTA Monomer | Ethoxylated trimethylolpropane triacrylate | 28961-43-5 |

| Photoresist Monomer | ||

| IPAMA Monomer | 2-isopropyl-2-adamantyl methacrylate | 297156-50-4 |

| ECPMA Monomer | 1-Ethylcyclopentyl Methacrylate | 266308-58-1 |

| ADAMA Monomer | 1-Adamantyl Methacrylate | 16887-36-8 |

| Methacrylates monomer | ||

| TBAEMA Monomer | 2-(Tert-butylamino)ethyl methacrylate | 3775-90-4 |

| NBMA Monomer | n-Butyl methacrylate | 97-88-1 |

| MEMA Monomer | 2-Methoxyethyl Methacrylate | 6976-93-8 |

| i-BMA Monomer | Isobutyl methacrylate | 97-86-9 |

| EHMA Monomer | 2-Ethylhexyl methacrylate | 688-84-6 |

| EGDMP Monomer | Ethylene glycol Bis(3-mercaptopropionate) | 22504-50-3 |

| EEMA Monomer | 2-ethoxyethyl 2-methylprop-2-enoate | 2370-63-0 |

| DMAEMA Monomer | N,M-Dimethylaminoethyl methacrylate | 2867-47-2 |

| DEAM Monomer | Diethylaminoethyl methacrylate | 105-16-8 |

| CHMA Monomer | Cyclohexyl methacrylate | 101-43-9 |

| BZMA Monomer | Benzyl methacrylate | 2495-37-6 |

| BDDMP Monomer | 1,4-Butanediol Di(3-mercaptopropionate) | 92140-97-1 |

| BDDMA Monomer | 1,4-Butanedioldimethacrylate | 2082-81-7 |

| AMA Monomer | Allyl methacrylate | 96-05-9 |

| AAEM Monomer | Acetylacetoxyethyl methacrylate | 21282-97-3 |

| Acrylates Monomer | ||

| IBA Monomer | Isobutyl acrylate | 106-63-8 |

| EMA Monomer | Ethyl methacrylate | 97-63-2 |

| DMAEA Monomer | Dimethylaminoethyl acrylate | 2439-35-2 |

| DEAEA Monomer | 2-(diethylamino)ethyl prop-2-enoate | 2426-54-2 |

| CHA Monomer | cyclohexyl prop-2-enoate | 3066-71-5 |

| BZA Monomer | benzyl prop-2-enoate | 2495-35-4 |