Description

Monofunctional Monomer

Each molecule of the monofunctional monomer contains only one group that can participate in the photocuring reaction, so it generally has the following characteristics: High conversion rate, small volume shrinkage, slow curing speed, low cross-linking density and low viscosity.

-

CHLUMICRYL® DCPEOA Monomer / Dicyclopentenyloxyethyl Acrylate CAS 65983-31-5

Read more -

CHLUMICRYL® EOEOEA Monomer / 2-(2-Ethoxyethoxy)ethyl acrylate CAS 7328-17-8

Read more -

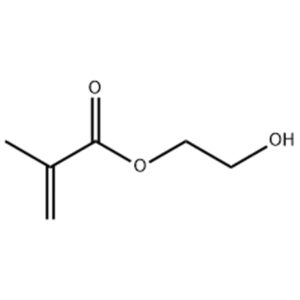

CHLUMICRYL® HEMA Monomer / 2-hydroxyethyl methacrylate CAS 868-77-9

Read more -

CHLUMICRYL® HPMA Monomer / 2-Hydroxypropyl methacrylate CAS 27813-02-1

Read more -

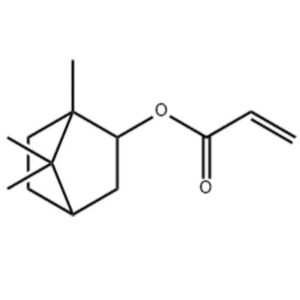

CHLUMICRYL® IBOA Monomer / Isobornyl acrylate CAS 5888-33-5

Read more -

CHLUMICRYL® IBOMA / Isobornyl methacrylate CAS 7534-94-3

Read more -

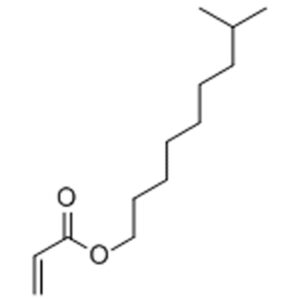

CHLUMICRYL® IDA Monomer / Isodecyl acrylate CAS 1330-61-6

Read more -

CHLUMICRYL® LMA Monomer / Lauryl methacrylate CAS 142-90-5

Read more -

CHLUMICRYL® NP-4EA Monomer / (4) ethoxylated nonylphenol CAS 50974-47-5

Read more -

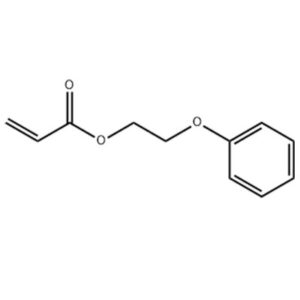

CHLUMICRYL® PHEA Monomer / 2-PHENOXYETHYL ACRYLATE CAS 48145-04-6

Read more -

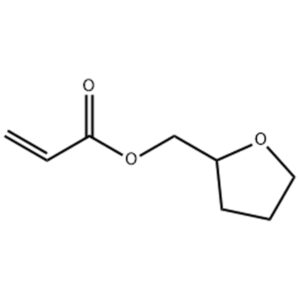

CHLUMICRYL® THFA Monomer / Tetrahydrofurfuryl acrylate CAS 2399-48-6

Read more

Di-functional Monomer

Each molecule of the bifunctional monomer contains two active groups that can participate in the photocuring reaction, so the photocuring rate is faster than that of the monofunctional monomer, and crosslinking occurs during film formation, which is beneficial to improve the physical and mechanical properties and chemical resistance of the cured film.Due to the increase in molecular weight, the viscosity also increases accordingly but still maintains good dilution, less volatility, and lower odor. Difunctional monomers are widely used in photocurable coatings and ink products.

Difunctional monomers are mostly diol structures, mainly ethylene glycol diacrylates, propylene glycol diacrylates and other glycol diacrylates.

-

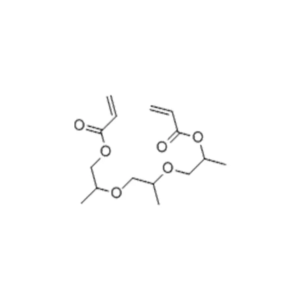

CHLUMICRYL® DPGDA Monomer / Dipropylene Glycol Dienoate CAS 57472-68-1

Read more -

CHLUMICRYL® HDDA Monomer / Hexamethylene Diacrylate CAS 13048-33-4

Read more -

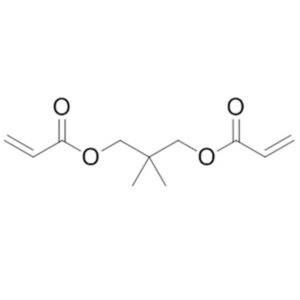

CHLUMICRYL® NPGDA Monomer / Neopentyl glycol diacrylate CAS 2223-82-7

Read more -

CHLUMICRYL® PEGDA Monomer / Polyethylene Glycol Diacrylate CAS 26570-48-9

Read more -

CHLUMICRYL® PEGDMA Monomer / Poly(ethylene glycol) dimethacrylate CAS 25852-47-5

Read more -

CHLUMICRYL® PO2-NPGDA Cas 84170-74-1

Read more -

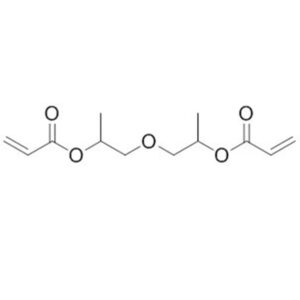

CHLUMICRYL® TPGDA Monomer / Tripropylene glycol diacrylate CAS 42978-66-5

Read more

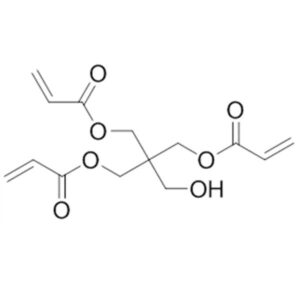

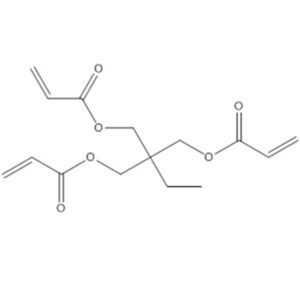

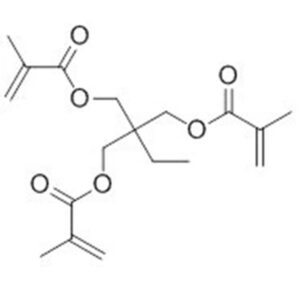

Trifunctional Monomer

Trifunctional monomer means that each molecule contains three active groups that can participate in the photocuring reaction, so it has fast photocuring rate, high crosslinking density, high hardness and brittleness of cured film, and excellent resistance.

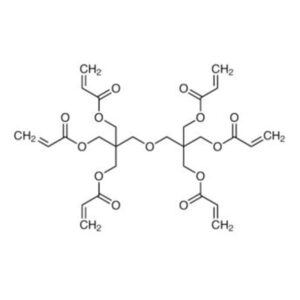

Multifunctional monomer

1. Multifunctional monomer means that each molecule contains three or more active groups that can participate in the photocuring reaction, so its photocuring rate is fast, the crosslinking density is large, the cured film has high hardness, high brittleness, and excellent resistance.

2. At the same time, due to the increased molecular weight, low volatility and high viscosity, the dilution is worse than that of low-functional monomers.

3. Multifunctional monomers are usually not mainly used to reduce the viscosity of the system, but to adjust certain aspects of the paint film according to actual needs, such as increasing the curing speed, improving hardness, scratch resistance, etc.

Mohammed Khan –

Quick delivery, impeccable quality. A delightful experience, highly recommended for all your shopping needs!