Description

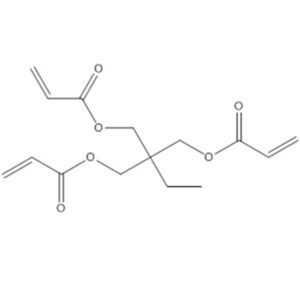

EO3-TMPTA Monomer / Ethoxylated trimethylolpropane triacrylate CAS 28961-43-5

| Appearance | Colorless or light yellow clear liquid |

| Solid Content(wt) | ≥99.0% |

| Color (Pt-Co) | ≤60APHA |

| Viscosity @25 deg. C | 45-80cps |

| Acid Value | ≤1.0mg KOH/g |

| Moisture (K.F) | ≤0.2% |

EO3-TMPTA Applications

In terms of the versatility of its applications, EO3-TMPTA can be considered “versatile” and performs well in many coatings and printing fields. In terms of wood coatings, wood, as a traditional and widely used building and decorative material, has always attracted attention for its surface protection and decorative needs. Wood coatings formulated with EO3-TMPTA can provide wood with excellent wear and weather resistance, effectively preventing wood from problems such as decay, discoloration and deformation due to long-term exposure to the natural environment. For example, the use of coatings containing EO3-TMPTA on outdoor wooden structures such as wooden houses and boardwalks, as well as high-quality indoor wooden furniture, can significantly extend the service life of the wood while maintaining its attractive appearance and good texture.

When it comes to PVC coatings, PVC materials are widely used in many industries such as construction, packaging, and electronics due to their unique physical and chemical properties. However, they also face problems such as poor scratch resistance and poor gloss retention. The addition of EO3-TMPTA . Through its efficient radiation curing reaction mechanism, it can form a tightly cross-linked polymer network, enhancing the hardness and wear resistance of the PVC coating. This makes the surface of the PVC product less prone to damage during long-term use, and it can maintain good gloss and color stability. Take common PVC pipes and decorative panels as an example. After being treated with EO3-TMPTA modified coatings, not only do they have a brighter appearance, but they also better resist external friction and impact during daily handling, installation and use, reducing the occurrence of surface scratches and wear, thereby improving product quality and added value.

In the field of plastic coatings, there are many different types of plastics, each with its own unique surface characteristics and performance requirements. EO3-TMPTA, with its good compatibility and reactivity, can closely bond with different types of plastic substrates to provide excellent protection and decorative effects for plastics. For some high-performance plastics, such as engineering plastics used in automotive parts and electronic equipment housings, the use of coatings containing EO3-TMPTA can improve the surface hardness, chemical resistance and UV resistance of the plastic, meeting the requirements of these products in complex use environments. For example, plastic parts in automotive interiors treated with this coating not only resist daily scratches and chemical attacks, but also maintain their color vibrancy in long-term light exposure, improving the overall quality and durability of the automotive interior.

Metal coatings are also an important area where EO3-TMPTA excels. Metal materials are widely used in industrial production and daily life, but metals are susceptible to problems such as oxidation and corrosion. Metal coating systems involving EO3-TMPTA can form a dense protective film on the metal surface, effectively blocking the intrusion of oxygen, moisture and other corrosive media, thereby significantly improving the corrosion resistance of the metal. At the same time, through reasonable formulation design, it can also give the metal coating good adhesion, flexibility and decorative properties, making it widely used in industries such as architectural curtain walls, metal furniture, and machinery manufacturing. For example, in the surface protection of some large steel buildings, the use of metal coatings containing EO3-TMPTA not only ensures that the building does not rust in the long-term wind and rain, but also can present different colors and gloss effects according to design requirements, achieving the dual goals of protection and aesthetics.

EO3-TMPTA also plays an indispensable role in the printing industry. In offset printing inks, with the continuous increase in printing speed and the increasingly stringent requirements for printing quality, the drying speed and curing properties of the ink have become key factors. EO3-TMPTA, as a radiation-curing monomer, can undergo a rapid polymerization reaction under the action of a radiation source such as ultraviolet light, achieving rapid drying and curing of the ink. This greatly improves printing production efficiency, while at the same time reducing the problem of smudging and adhesion of the printed matter during the drying process, ensuring the clarity and vibrancy of the printed matter. For example, in the printing process of some high-quality commercial printed products, such as exquisite picture albums and magazine covers, the use of offset printing inks containing EO3-TMPTA can make the printed patterns clearer and sharper, and the colors more full and bright, meeting the market demand for high-quality printed products.

In the field of flexographic printing and screen printing, due to the particularity of the printing method, there are unique requirements for the rheological and curing properties of the ink. The addition of EO3-TMPTA can optimize the rheological properties of the ink, giving it better transferability and printability during the printing process. At the same time, radiation curing can achieve rapid drying, improve production efficiency and expand the application scope of these two printing methods. For example, in the fields of food packaging and label printing, flexographic and screen printing using inks containing EO3-TMPTA can meet the requirements of fast production and environmental protection while ensuring print quality, providing a reliable solution for product packaging and labeling.

In addition, EO3-TMPTA also makes a unique contribution in the field of varnishes. Varnishes are mainly used to protect and decorate the surface of objects, while also displaying the original texture and color of the object. Varnish formulations with EO3-TMPTA provide good hardness, abrasion resistance and chemical resistance, so that the varnish can protect the surface of the object while maintaining a long-lasting luster and transparency. For example, in the varnish treatment of some high-end wooden handicrafts and musical instrument surfaces, the use of varnishes containing EO3-TMPTA not only highlights the natural texture and feel of the wood, but also provides long-lasting protection against daily wear and tear and stains on the surface, extending the service life and artistic value of the handicrafts and musical instruments.

Looking to the future, with the continuous advancement of technology and people’s ever-increasing demand for material performance, we can imagine that if the molecular structure and synthesis process of EO3-TMPTA can be further optimized, is it possible to develop a radiation-curable monomer with even more outstanding performance? For example, by introducing new functional groups or changing the length and branching structure of the molecular chain, a more perfect balance can be achieved in terms of curing speed, hardness, flexibility, adhesion, and environmental performance. This will not only bring new technological breakthroughs and product upgrades to the existing coatings and printing industries, but also expand their applications in emerging fields such as 3D printing materials and electronic packaging materials, opening up broader prospects for the development of materials science.

EO3-TMPTA Packaging and Shipping

Packing:25kg/drum or 200 kg/drum

Delivery:with in 5-7 working days.

EO3-TMPTA Storage

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

| Polythiol/Polymercaptan | ||

| DMES Monomer | Bis(2-mercaptoethyl) sulfide | 3570-55-6 |

| DMPT Monomer | THIOCURE DMPT | 131538-00-6 |

| PETMP Monomer | 7575-23-7 | |

| PM839 Monomer | Polyoxy(methyl-1,2-ethanediyl) | 72244-98-5 |

| Monofunctional Monomer | ||

| HEMA Monomer | 2-hydroxyethyl methacrylate | 868-77-9 |

| HPMA Monomer | 2-Hydroxypropyl methacrylate | 27813-02-1 |

| THFA Monomer | Tetrahydrofurfuryl acrylate | 2399-48-6 |

| HDCPA Monomer | Hydrogenated dicyclopentenyl acrylate | 79637-74-4 |

| DCPMA Monomer | Dihydrodicyclopentadienyl methacrylate | 30798-39-1 |

| DCPA Monomer | Dihydrodicyclopentadienyl Acrylate | 12542-30-2 |

| DCPEMA Monomer | Dicyclopentenyloxyethyl Methacrylate | 68586-19-6 |

| DCPEOA Monomer | Dicyclopentenyloxyethyl Acrylate | 65983-31-5 |

| NP-4EA Monomer | (4) ethoxylated nonylphenol | 50974-47-5 |

| LA Monomer | Lauryl acrylate / Dodecyl acrylate | 2156-97-0 |

| THFMA Monomer | Tetrahydrofurfuryl methacrylate | 2455-24-5 |

| PHEA Monomer | 2-PHENOXYETHYL ACRYLATE | 48145-04-6 |

| LMA Monomer | Lauryl methacrylate | 142-90-5 |

| IDA Monomer | Isodecyl acrylate | 1330-61-6 |

| IBOMA Monomer | Isobornyl methacrylate | 7534-94-3 |

| IBOA Monomer | Isobornyl acrylate | 5888-33-5 |

| EOEOEA Monomer | 2-(2-Ethoxyethoxy)ethyl acrylate | 7328-17-8 |

| Multifunctional monomer | ||

| DPHA Monomer | 29570-58-9 | |

| DI-TMPTA Monomer | DI(TRIMETHYLOLPROPANE) TETRAACRYLATE | 94108-97-1 |

| Acrylamide monomer | ||

| ACMO Monomer | 4-acryloylmorpholine | 5117-12-4 |

| Di-functional Monomer | ||

| PEGDMA Monomer | Poly(ethylene glycol) dimethacrylate | 25852-47-5 |

| TPGDA Monomer | Tripropylene glycol diacrylate | 42978-66-5 |

| TEGDMA Monomer | Triethylene glycol dimethacrylate | 109-16-0 |

| PO2-NPGDA Monomer | Propoxylate neopentylene glycol diacrylate | 84170-74-1 |

| PEGDA Monomer | Polyethylene Glycol Diacrylate | 26570-48-9 |

| PDDA Monomer | Phthalate diethylene glycol diacrylate | |

| NPGDA Monomer | Neopentyl glycol diacrylate | 2223-82-7 |

| HDDA Monomer | Hexamethylene Diacrylate | 13048-33-4 |

| EO4-BPADA Monomer | ETHOXYLATED (4) BISPHENOL A DIACRYLATE | 64401-02-1 |

| EO10-BPADA Monomer | ETHOXYLATED (10) BISPHENOL A DIACRYLATE | 64401-02-1 |

| EGDMA Monomer | Ethylene glycol dimethacrylate | 97-90-5 |

| DPGDA Monomer | Dipropylene Glycol Dienoate | 57472-68-1 |

| Bis-GMA Monomer | Bisphenol A Glycidyl Methacrylate | 1565-94-2 |

| Trifunctional Monomer | ||

| TMPTMA Monomer | Trimethylolpropane trimethacrylate | 3290-92-4 |

| TMPTA Monomer | Trimethylolpropane triacrylate | 15625-89-5 |

| PETA Monomer | 3524-68-3 | |

| GPTA ( G3POTA ) Monomer | GLYCERYL PROPOXY TRIACRYLATE | 52408-84-1 |

| EO3-TMPTA Monomer | Ethoxylated trimethylolpropane triacrylate | 28961-43-5 |

| Photoresist Monomer | ||

| IPAMA Monomer | 2-isopropyl-2-adamantyl methacrylate | 297156-50-4 |

| ECPMA Monomer | 1-Ethylcyclopentyl Methacrylate | 266308-58-1 |

| ADAMA Monomer | 1-Adamantyl Methacrylate | 16887-36-8 |

| Methacrylates monomer | ||

| TBAEMA Monomer | 2-(Tert-butylamino)ethyl methacrylate | 3775-90-4 |

| NBMA Monomer | n-Butyl methacrylate | 97-88-1 |

| MEMA Monomer | 2-Methoxyethyl Methacrylate | 6976-93-8 |

| i-BMA Monomer | Isobutyl methacrylate | 97-86-9 |

| EHMA Monomer | 2-Ethylhexyl methacrylate | 688-84-6 |

| EGDMP Monomer | Ethylene glycol Bis(3-mercaptopropionate) | 22504-50-3 |

| EEMA Monomer | 2-ethoxyethyl 2-methylprop-2-enoate | 2370-63-0 |

| DMAEMA Monomer | N,M-Dimethylaminoethyl methacrylate | 2867-47-2 |

| DEAM Monomer | Diethylaminoethyl methacrylate | 105-16-8 |

| CHMA Monomer | Cyclohexyl methacrylate | 101-43-9 |

| BZMA Monomer | Benzyl methacrylate | 2495-37-6 |

| BDDMP Monomer | 1,4-Butanediol Di(3-mercaptopropionate) | 92140-97-1 |

| BDDMA Monomer | 1,4-Butanedioldimethacrylate | 2082-81-7 |

| AMA Monomer | Allyl methacrylate | 96-05-9 |

| AAEM Monomer | Acetylacetoxyethyl methacrylate | 21282-97-3 |

| Acrylates Monomer | ||

| IBA Monomer | Isobutyl acrylate | 106-63-8 |

| EMA Monomer | Ethyl methacrylate | 97-63-2 |

| DMAEA Monomer | Dimethylaminoethyl acrylate | 2439-35-2 |

| DEAEA Monomer | 2-(diethylamino)ethyl prop-2-enoate | 2426-54-2 |

| CHA Monomer | cyclohexyl prop-2-enoate | 3066-71-5 |

| BZA Monomer | benzyl prop-2-enoate | 2495-35-4 |

Reviews

There are no reviews yet.