What is the difference between thin coat powder coatings and conventional powder coatings?

The advantages of powder coating are that a single coating can get a thick coating film (50~150μm), high production efficiency, saving resources, reducing VOC emission, and meeting the requirements of modern environmental protection concept.

Therefore, powder coating has been developed greatly. However, the coating film of some products does not need to be too thick, for example, the thick coating film of household appliances has caused the increase of material cost for users, the bad grouping performance of painted parts, and even the problem of unstable mechanical properties of coating film coating online coatingol.com.

In order to reduce the coating cost and a spraying pass rate, thin powder coating has a special application area, thin and uniform coating film is a very important performance of thin powder coating film.

The film thickness of conventional powder coatings is 60-80μm, only to achieve the film thickness to ensure that the coated workpiece is completely covered, the film flatness and various performance indicators meet the requirements.

If the film thickness of conventional powder coatings is reduced to 45-60μm, it is very difficult to achieve the above performance and to ensure the uniformity of the powder on once and on the edges.

Therefore, the improvement of particle size distribution, covering power, leveling and charging efficiency of conventional powder coatings is the problem that must be solved to develop thin coating powder coatings.

According to the requirements of thin coating powder coatings and coating, through optimizing the formula, adjusting the production process, and combining the various spraying process parameters of the user, we have developed a thin coating type powder coating that can achieve uniform thin coating without changing the existing production equipment and curing conditions of the user, and only adjusting the spraying air pressure slightly.

Particle size distribution comparison

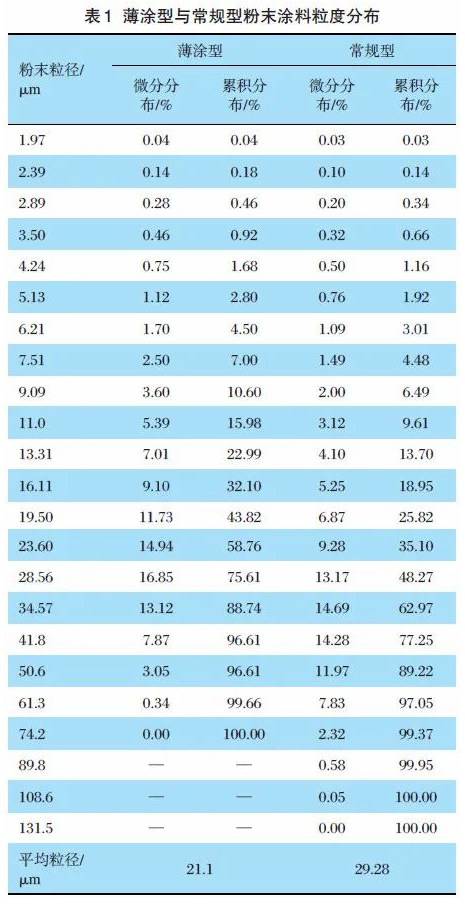

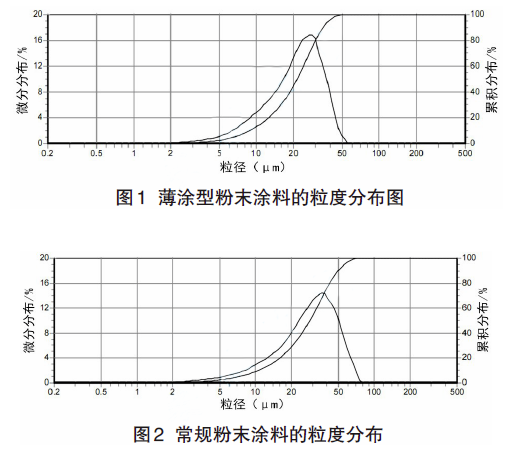

The particle size distribution of thin coating and conventional powder coating is shown in Table 1 and Figure 1 and Figure 2.

From the comparison of data in Table 1, it can be seen that the particle size distribution of thin coated and conventional powder coatings are obviously different, with an average particle size of 21.1μm and 29.28μm respectively.

From the film thickness, the thin coating type film thickness of 45-60μm can achieve satisfactory film coverage, flatness and appearance effect and conventional powder coatings are basically the same; while the conventional type needs 60-80μm to meet the requirements.

The thin coating powder film thickness, covering power decreases, by increasing the amount of pigment, adding dispersion additives and other methods can improve the dispersion of color filler, improve the covering power; powder coating film leveling is through the particle size distribution adjustment, that is, the average particle size adjustment to achieve.

The average particle size of thin powder coating is small, the dry powder fluidity, storage stability, powder rate and other properties become poor, but by adjusting the powder coating formula, moderate addition of power enhancers, loose additives, etc. can be improved to meet user requirements.

The coating effect of thin coating powder coating

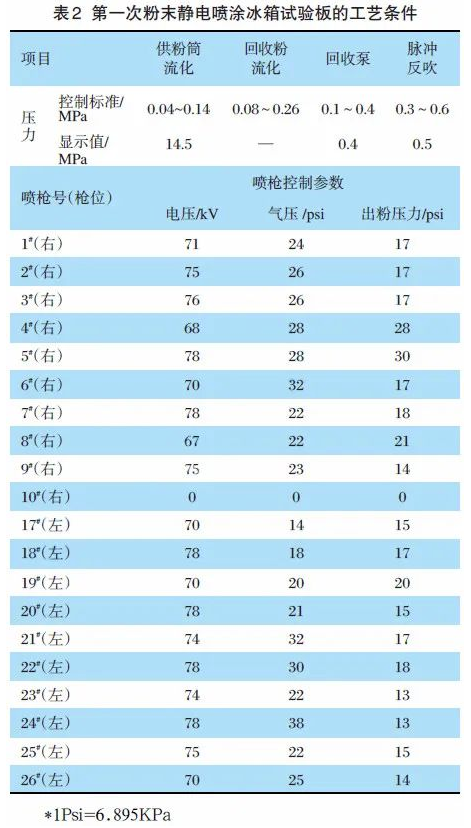

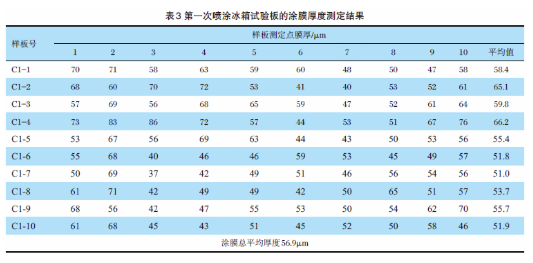

To thin coating type powder coating in the refrigerator spraying line for spraying test. The process conditions of the first powder electrostatic spraying test are shown in Table 2. 10 refrigerator test plates are taken for spraying, and the thickness of the coating film is measured at 10 points on each plate, and the measurement results are shown in Table 3.

Film thickness: the maximum value of 66.2μm, the minimum value of 51.8μm, the total average value of 56.9μm.

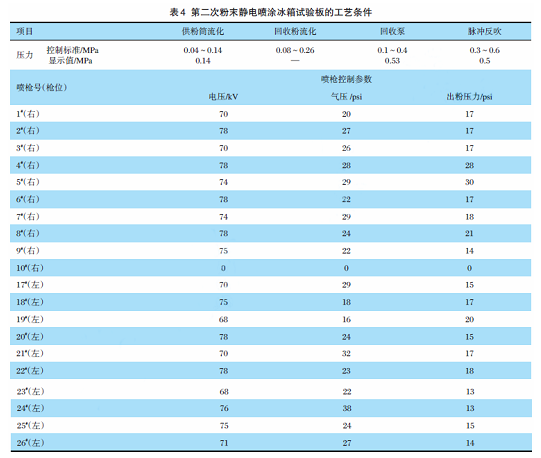

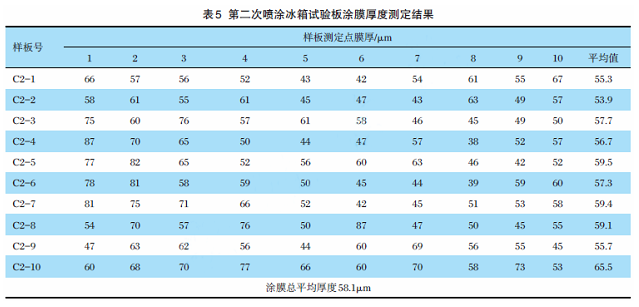

The second thin coating type powder coating electrostatic spraying refrigerator test plate process conditions as shown in Table 4, 10 pieces of refrigerator test plate spraying, and each plate to determine the film thickness of 10 points (Table 5).

The average thickness of the powder coating film of the two tests was 57.5μm, which was lower than the low limit value of 60μm for conventional powder coating film.

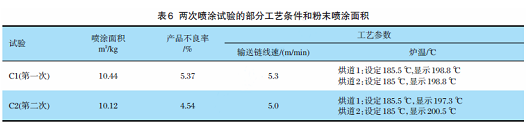

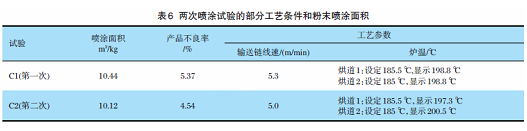

Some of the process conditions and the area of the workpiece that can be sprayed per unit mass of powder coating in the test are shown in Table 6 for the thin coating type powder coating.

The above test results show that.

(1) the powder coating area per kg in both tests was above 10.0 m2/kg, with an average value of 10.28 m2/kg.

(2) The defective rate of the plate is stable at about 5%.

(3) The thickness of the coating film is relatively stable, with the maximum film thickness of 76 μm and the minimum value of 37 μm in the first test, and the maximum film thickness of 87 μm and the minimum value of 42 μm in the second test.

(4) The coating line process parameters are basically stable, and the coating film leveling and covering power are good.

It should be noted that, compared with conventional powder coatings, although the thin coating powder coatings can get a thinner film, but from the film thickness measurement results, the film thickness uniformity needs to be improved, the key problem is the stability of the powder supply system needs to improve the powder supply.

Comparison of spraying characteristics

Thin coating type powder coatings and conventional powder coatings electrostatic spraying refrigerator, compare the film thickness and the spraying area per kilogram of powder, the test results are shown in Table 7.

Test results show that.

(1) after changing to thin coating type powder coating spray sample, each kilogram of thin coating powder than conventional powder can spray 2.63 m2 more, saving powder coating dosage 34.38%.

(2) compared with conventional powder coatings, thin coating type powder coatings, the average film thickness reduced by 25μm; the difference between the maximum and minimum film thickness from the conventional powder coatings of about 120μm reduced to 50μm, the coating product defect rate decreased by 6.04%.

(3) The thin coating powder coating has strong penetrating power when spraying, which obviously improves the dead corner powder rate, and the film thickness is more uniform than the conventional powder coating, which greatly reduces the coating cost and improves the coating efficiency.

Conclusion

From the above test results, the following conclusions can be drawn.

(1) Through the adjustment of powder coating formulation, especially the regulation of powder coating particle size distribution, thin coating type powder coatings can be prepared.

(2) Through the adjustment of the coating process, the thin coating type powder coating can be used to obtain a thin coating film with an average thickness of less than 60μm, which not only saves the amount of powder coating, but also reduces the coating cost.

ink raw materials : UV Photoinitiator Same series products

| Product name | CAS NO. | Chemical name |

| lcnacure® TPO | 75980-60-8 | Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide |

| lcnacure® TPO-L | 84434-11-7 | Ethyl (2,4,6-trimethylbenzoyl) phenylphosphinate |

| lcnacure® 819/920 | 162881-26-7 | Phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide |

| lcnacure® 819 DW | 162881-26-7 | Irgacure 819 DW |

| lcnacure® ITX | 5495-84-1 | 2-Isopropylthioxanthone |

| lcnacure® DETX | 82799-44-8 | 2,4-Diethyl-9H-thioxanthen-9-one |

| lcnacure® BDK/651 | 24650-42-8 | 2,2-Dimethoxy-2-phenylacetophenone |

| lcnacure® 907 | 71868-10-5 | 2-Methyl-4′-(methylthio)-2-morpholinopropiophenone |

| lcnacure® 184 | 947-19-3 | 1-Hydroxycyclohexyl phenyl ketone |

| lcnacure® MBF | 15206-55-0 | Methyl benzoylformate |

| lcnacure® 150 | 163702-01-0 | Benzene, (1-methylethenyl)-, homopolymer,ar-(2-hydroxy-2-methyl-1-oxopropyl) derivs |

| lcnacure® 160 | 71868-15-0 | Difunctional alpha hydroxy ketone |

| lcnacure® 1173 | 7473-98-5 | 2-Hydroxy-2-methylpropiophenone |

| lcnacure® EMK | 90-93-7 | 4,4′-Bis(diethylamino) benzophenone |

| lcnacure® PBZ | 2128-93-0 | 4-Benzoylbiphenyl |

| lcnacure® OMBB/MBB | 606-28-0 | Methyl 2-benzoylbenzoate |

| lcnacure® 784/FMT | 125051-32-3 | BIS(2,6-DIFLUORO-3-(1-HYDROPYRROL-1-YL)PHENYL)TITANOCENE |

| lcnacure® BP | 119-61-9 | Benzophenone |

| lcnacure® 754 | 211510-16-6 | Benzeneacetic acid, alpha-oxo-, Oxydi-2,1-ethanediyl ester |

| lcnacure® CBP | 134-85-0 | 4-Chlorobenzophenone |

| lcnacure® MBP | 134-84-9 | 4-Methylbenzophenone |

| lcnacure® EHA | 21245-02-3 | 2-Ethylhexyl 4-dimethylaminobenzoate |

| lcnacure® DMB | 2208-05-1 | 2-(Dimethylamino)ethyl benzoate |

| lcnacure® EDB | 10287-53-3 | Ethyl 4-dimethylaminobenzoate |

| lcnacure® 250 | 344562-80-7 | (4-Methylphenyl) [4-(2-methylpropyl)phenyl] iodoniumhexafluorophosphate |

| lcnacure® 369 | 119313-12-1 | 2-Benzyl-2-(dimethylamino)-4′-morpholinobutyrophenone |

| lcnacure® 379 | 119344-86-4 | 1-Butanone, 2-(dimethylamino)-2-(4-methylphenyl)methyl-1-4-(4-morpholinyl)phenyl- |

| lcnacure® 938 | 61358-25-6 | Bis(4-tert-butylphenyl)iodonium hexafluorophosphate |

| lcnacure® 6992 MX | 75482-18-7 & 74227-35-3 | Cationic Photoinitiator UVI-6992 |

| lcnacure® 6992 | 68156-13-8 | Diphenyl(4-phenylthio)phenylsufonium hexafluorophosphate |

| lcnacure® 6993-S | 71449-78-0 & 89452-37-9 | Mixed type triarylsulfonium hexafluoroantimonate salts |

| lcnacure® 6993-P | 71449-78-0 | 4-Thiophenyl phenyl diphenyl sulfonium hexafluoroantimonate |

| lcnacure® 1206 | Photoinitiator APi-1206 |

UV ink raw materials : UV Monomer Same series products

| ACMO | 4-acryloylmorpholine | 5117-12-4 |

| ADAMA | 1-Adamantyl Methacrylate | 16887-36-8 |

| DCPEOA | Dicyclopentenyloxyethyl Acrylate | 65983-31-5 |

| DI-TMPTA | DI(TRIMETHYLOLPROPANE) TETRAACRYLATE | 94108-97-1 |

| DPGDA | Dipropylene Glycol Dienoate | 57472-68-1 |

| DPHA | Dipentaerythritol hexaacrylate | 29570-58-9 |

| ECPMA | 1-Ethylcyclopentyl Methacrylate | 266308-58-1 |

| EO10-BPADA | (10) ethoxylated bisphenol A diacrylate | 64401-02-1 |

| EO3-TMPTA | Ethoxylated trimethylolpropane triacrylate | 28961-43-5 |

| EO4-BPADA | (4) ethoxylated bisphenol A diacrylate | 64401-02-1 |

| EOEOEA | 2-(2-Ethoxyethoxy)ethyl acrylate | 7328-17-8 |

| GPTA ( G3POTA ) | GLYCERYL PROPOXY TRIACRYLATE | 52408-84-1 |

| HDDA | Hexamethylene diacrylate | 13048-33-4 |

| HEMA | 2-hydroxyethyl methacrylate | 868-77-9 |

| HPMA | 2-Hydroxypropyl methacrylate | 27813-02-1 |

| IBOA | Isobornyl acrylate | 5888-33-5 |

| IBOMA | Isobornyl methacrylate | 7534-94-3 |

| IDA | Isodecyl acrylate | 1330-61-6 |

| IPAMA | 2-isopropyl-2-adamantyl methacrylate | 297156-50-4 |

| LMA | Dodecyl 2-methylacrylate | 142-90-5 |

| NP-4EA | (4) ethoxylated nonylphenol | 2156-97-0 |

| NPGDA | Neopentyl glycol diacrylate | 2223-82-7 |

| PDDA | Phthalate diethylene glycol diacrylate | |

| PEGDA | Polyethylene Glycol Diacrylate | 26570-48-9 |

| PEGDMA | Poly(ethylene glycol) dimethacrylate | 25852-47-5 |

| PETA | PETA Monomer | 3524-68-3 |

| PHEA | 2-PHENOXYETHYL ACRYLATE | 48145-04-6 |

| PO2-NPGDA | NEOPENTYL GLYCOL PROPOXYLATE DIACRYLATE | 84170-74-1 |

| TEGDMA | Triethylene glycol dimethacrylate | 109-16-0 |

| THFA | Tetrahydrofurfuryl acrylate | 2399-48-6 |

| THFMA | Tetrahydrofurfuryl methacrylate | 2455-24-5 |

| TMPTA | Trimethylolpropane triacrylate | 15625-89-5 |

| TMPTMA | Trimethylolpropane trimethacrylate | 3290-92-4 |

| TPGDA | Tripropylene glycol diacrylate | 42978-66-5 |