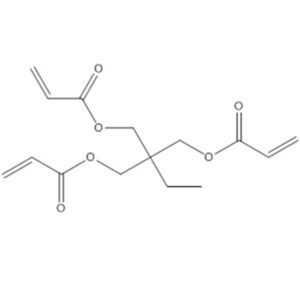

CHLUMICRYL® TMPTMA 单体/三羟甲基丙烷三甲基丙烯酸酯 CAS 3290-92-4

Chemical Name: Trimethylolpropane trimethacrylate

Other Name: TMPTMA; ACRYESTER TMP;MIRAMER M301;Trimethacrylate de propylidynetrimethyle ;Trimetacrilato de propilidintrimetilo;2,2-bis[(methacryloyloxy)methyl]butyl methacrylate (non-preferred name)

CAS No.: 3290-92-4

Molecular Fomula:338.39544

Molecular weight: 246.43

Appearance:colorless clear liquid

化验:98%

描述

TMPTMA Monomer / Trimethylolpropane trimethacrylate CAS 3290-92-4

外观

|

colorless clear liquid

|

化验

|

99.5%min

|

异构体

|

0.1%max

|

游离酸

|

0.2%max

|

This product can replace Trimethylolpropane trimethacrylate; ACRYESTER TMP;MIRAMER M301;Trimethacrylate de propylidynetrimethyle ;Trimetacrilato de propilidintrimetilo;2,2-bis[(methacryloyloxy)methyl]butyl methacrylate (non-preferred name).

Trimethylolpropane trimethacrylate Usage

1. Trimethylolpropane trimethacrylate can be used as a cross-linking agent for peroxide cross-linking. It is suitable for mixing POLYBUTADIENE DIACRYLATE, POLY(PROPYLENE-CO-ETHYLENE), EPDM RUBBER, Isoprene rubber, acrylonitrile-butadiene rubber.

2. Trimethylolpropane trimethacrylate can be used as a vulcanizing agent. When synthetic rubber is vulcanized with peroxide, TMPTMA can improve corrosion resistance, aging resistance and hardness, heat resistance. TMPTMA plasticizes during mixing and vulcanizes the original Hardening effect, can be used for NBR, EPDM, acrylic rubber.

3. Trimethylolpropane trimethacrylate can be used as a cross-linking agent. TMPTMA can reduce radiation dose, shorten radiation time, increase cross-linking density, and has the characteristics of low precision, high cross-linking degree, low vapor pressure and fast curing speed. It can be used for light-curing inks and light. Polymeric materials.

4. PVC is blended into the car body sealing agent, caulking agent and all the PVC solution molding.

5. Special rubber’s vulcanization-assisting activator, ethylene propylene propylene rafter rubber and EPDM rubber, chloro rubber, silicone rubber, polyurethane, ethylene/vinyl acetate copolymer (EVA), chlorinated polyethylene elastomer (CPE) and other special rubbers Vulcanization is very difficult, and organic peroxides (such as DCP, BPO) are generally used for vulcanization. If a single organic peroxide is used for vulcanization, the vulcanization time is too long and the vulcanization is insufficient, and it is difficult to ensure good mechanical and physical properties. Therefore, TMPTMA must be added as a vulcanizing agent to achieve good results.

6. For example, organic fluorine rubber, etc., when using DCP for vulcanization, if the additive 1~4% TMPTMA is used as a vulcanizing agent, it can not only greatly shorten the vulcanization time, increase the degree of vulcanization, and reduce the amount of DCP, but also significantly improve the machinery of the product. Strength, wear resistance, solvent resistance and corrosion resistance etc. In the vulcanization process of fluorine-containing rubber, the double bond in the TMPTMA molecule not only participates in the vulcanization cross-linking reaction, but also acts as a hydrogen halide (HF, HCL, etc.) acceptor, absorbing the hydrogen halide released during processing, thereby It not only improves the product quality, but also greatly reduces the corrosiveness of the vulcanized rubber. The rubber compound containing TMPTMA has a plasticizing effect during mixing and a hardening effect after vulcanization.

Trimethylolpropane trimethacrylate Packaging and Shipping

Packing: 1/kg; 200kg/drum

Delivery: by sea, air and DHL

Trimethylolpropane trimethacrylate Storage

Store at low temperature and avoid light.

立即联系我们!

如果您需要价格和样品测试,请在下表中填写您的联系信息,我们通常会在 24 小时内与您联系。您也可以给我发电子邮件 info@longchangchemical.com 请在工作时间(UTC+8 周一至周六,上午 8:30 至下午 6:00)或使用网站即时聊天工具获得及时回复。

The importance of the glass transition temperature (Tg) of acrylic resins, which are commonly used in coating formulations, is briefly described as an example

The glass transition temperature (Tg) is the lowest temperature at which the polymer chain segments can move, and is directly related to the flexibility of the molecular chains. For acrylic resins commonly used in coating formulations, the film becomes soft above its glass transition temperature, so they are usually used below the glass transition temperature, so we also want to use acrylic resins with a higher glass transition temperature. The glass transition temperature (Tg) of acrylic resins is a very important technical indicator, which must be designed and selected correctly, and its importance is mainly expressed in the following aspects.

One, the engineer in the design of paint formulations with acrylic resin, once the coating species, performance and other comprehensive requirements to determine the glass transition temperature of acrylic resin Tg, basically also determines the choice of synthetic resin monomer, but also basically determines the performance of acrylic resin and paint after the performance of the paint. The higher the Tg value of the acrylic resin, the better the solvent and corrosion resistance of the coating film; conversely, the lower the Tg value of the resin, the worse the corrosion and solvent resistance of the coating film. Therefore, among the many technical indicators of acrylic resins, the Tg value has a greater impact on the resin and the performance of the coating film.

Second, under the same acrylic resin synthesis reaction conditions, the higher the Tg of the resin, the greater the final viscosity of the resin reaction, that is, the higher the average molecular weight; conversely, the lower the Tg of the resin, the lower the final viscosity of the resin reaction, that is, the lower the average molecular weight.

The higher the Tg value, the harder the film and the stronger the scratch resistance, but care should be taken to adjust the paint formulation and not to make the film brittle; conversely, the lower the Tg value, the lower the film hardness and the worse the scratch resistance. We often encounter high temperatures in summer when the film is easy to become soft, back to sticky, easy to be contaminated phenomenon, which is the film-forming resin Tg high or low impact on the film hardness and scratch resistance of the visual performance.

Fourth, the higher the Tg of the acrylic resin, the better the solvent release of the coating, the better the dry rate of the film after painting; conversely, the worse the solvent release, the worse the dry rate of the film after painting the resin.

Liam Carter -

Swift delivery, exceptional quality. Couldn’t ask for more! Highly satisfied with my purchase.