설명

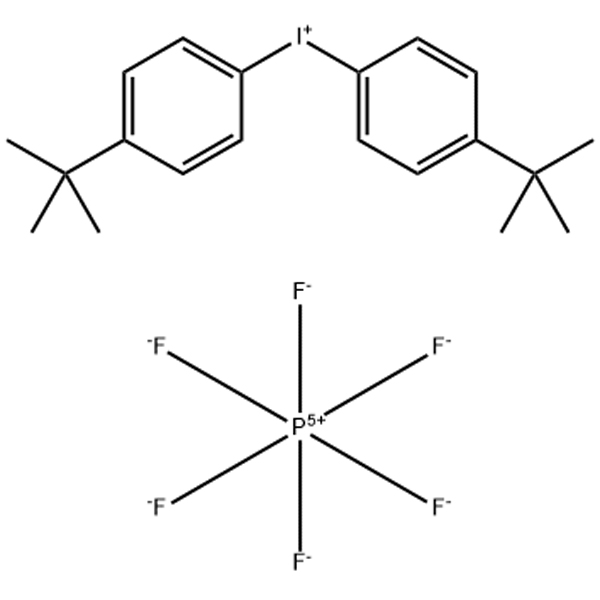

광개시제 938 / 스피드큐어 938 CAS 61358-25-6

동의어: 동의어Speedcure 938

사양

| 모양 | 흰색 분말 |

| 분석 | 98% 분 |

| 녹는 범위 | 170-180 ℃ |

| 건조 시 손실 | 최대 1% |

| 최대 흡수 λ | 267nm |

속성

애플리케이션

⦁ 투명 코팅

⦁ 색소 시스템

⦁ LED 경화

⦁ 전자 제품

⦁ 접착제

⦁ 3D 프린팅

패키지: 드럼, 보테.

저장소:

직사광선을 피해 서늘하고 건조한 곳에 보관하세요.

지금 문의하세요!

가격이 필요한 경우 아래 양식에 연락처 정보를 입력해 주시면 보통 24시간 이내에 연락드리겠습니다. 이메일을 보내셔도 됩니다. info@longchangchemical.com 근무 시간(오전 8시 30분~오후 6시, 월~토요일)에 문의하거나 웹사이트 라이브 채팅을 이용하면 신속하게 답변을 받을 수 있습니다.

| 광개시제 TPO | CAS 75980-60-8 |

| 광개시제 TMO | CAS 270586-78-2 |

| 광개시제 PD-01 | CAS 579-07-7 |

| 광개시제 PBZ | CAS 2128-93-0 |

| 광개시제 OXE-02 | CAS 478556-66-0 |

| 광개시제 OMBB | CAS 606-28-0 |

| 광개시제 MPBZ(6012) | CAS 86428-83-3 |

| 포토 이니시에이터 MBP | CAS 134-84-9 |

| 광개시제 MBF | CAS 15206-55-0 |

| 광개시제 LAP | CAS 85073-19-4 |

| 광개시제 ITX | CAS 5495-84-1 |

| 광개시제 EMK | CAS 90-93-7 |

| 광개시제 EHA | CAS 21245-02-3 |

| 광개시제 EDB | CAS 10287-53-3 |

| 광개시제 DETX | CAS 82799-44-8 |

| 광개시제 CQ / 캄포퀴논 | CAS 10373-78-1 |

| 광개시제 CBP | CAS 134-85-0 |

| 광개시제 BP / 벤조페논 | CAS 119-61-9 |

| 광개시제 BMS | CAS 83846-85-9 |

| 포토이니시에이터 938 | CAS 61358-25-6 |

| 포토이니시에이터 937 | CAS 71786-70-4 |

| 포토이니시에이터 819 DW | CAS 162881-26-7 |

| 광개시제 819 | CAS 162881-26-7 |

| 광개시제 784 | CAS 125051-32-3 |

| 광개시제 754 | CAS 211510-16-6 442536-99-4 |

| 포토이니시에이터 6993 | CAS 71449-78-0 |

| 포토이니시에이터 6976 | CAS 71449-78-0 89452-37-9 108-32-7 |

| 광개시제 379 | CAS 119344-86-4 |

| 광개시제 369 | CAS 119313-12-1 |

| 광개시제 160 | CAS 71868-15-0 |

| 광개시제 1206 | |

| 포토이니시에이터 1173 | CAS 7473-98-5 |

리뷰

아직 리뷰가 없습니다.