ACMO Monomer Application scenarios

1. Biomedical and Tissue Engineering

Hydrogel scaffolds, drug-releasing carriers, cell culture matrices, tissue regeneration materials

Excellent biocompatibility, biodegradable, controllable network structure, capable of mimicking extracellular matrices

2. Industrial Coatings and Adhesives

UV-curable coatings (plastics, metals), inks, adhesives, flexible printing plates

Rapid UV curing forms flexible, highly transparent coatings

3. Microfluidics and Precision Manufacturing

Microfluidic chips, biosensors, photoresists

Resistant to non-specific protein adsorption, low gas permeability, suitable for intricate microstructures

4. Novel Materials Research

Smart hydrogels (e.g., humidity-responsive actuators), flexible electronics, superabsorbent materials

Can deform in response to environmental stimuli (e.g., humidity), enabling fabrication of flexible devices and sensors

5. Scientific Research & Biochemistry

Protein/peptide modification (PEGylation), ligand studies, nanomaterial synthesis

Improves solubility and stability of biomolecules while reducing immunogenicity

💡 Key Characteristics & Application Considerations

Several critical points warrant special attention when using or selecting PEGDA:

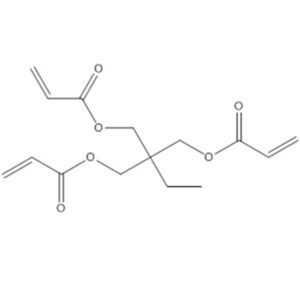

Molecular Weight and Form:

PEGDA is not a single substance but a series of products. Its physical form (liquid or solid) and the properties of the final polymer (e.g., flexibility, swelling degree) are highly dependent on the molecular weight of its polyethylene glycol segments. For example, PEG(200)DA is a low-viscosity liquid, while PEG(10000)DA is a solid. When purchasing, the required molecular weight must be specified based on experimental or production needs.

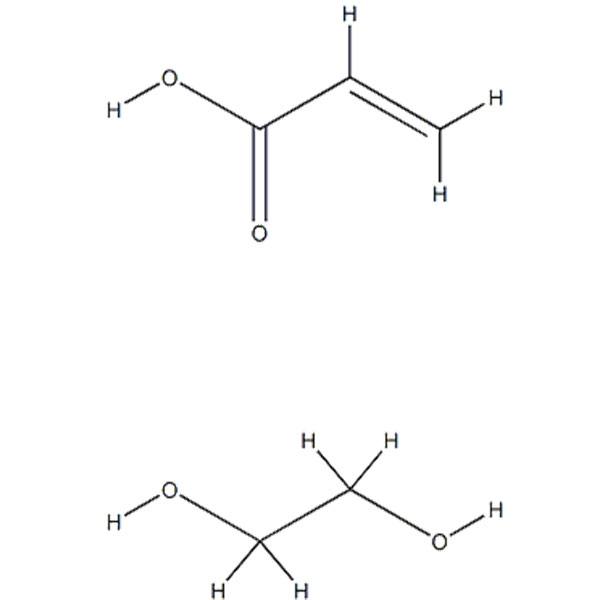

Reaction Characteristics:

The acrylic ester group at the PEGDA end enables radical polymerization reactions, commonly initiated by light (UV) for rapid curing and shaping. This property forms the basis for its use in light-curing coatings and 3D bioprinting.

Safety and Storage:

PEGDA monomer may cause skin and eye irritation. Commercial products typically contain trace amounts of polymerization inhibitors (e.g., BHT) to enhance storage stability. It is generally recommended to store at -20°C in a dark, dry environment.

Veronica Sullivan –

The product quality was exceptional and the delivery was super speedy