IBOA Monomer Application scenarios

1. Coatings and Inks

· Radiation-curable (UV/EB) coatings: Used as reactive diluents in topcoats for substrates such as wood, plastics, and metals.

· Specialty inks: Such as outdoor inkjet and polyethylene film printing inks.

· High-solids coatings: Reduces system viscosity and lowers VOC emissions.

· Automotive, marine, and industrial coatings: Enhances coating weatherability, chemical resistance, and decorative properties.

Effectively reduces viscosity, improves flow properties, lowers volume shrinkage, enhances adhesion, and provides a good balance of hardness and flexibility.

2. Adhesives

· Pressure-Sensitive Adhesives (PSA): Used in manufacturing high-performance acrylic PSAs to improve tack.

· Other Industrial Adhesives: Participates in polymerization as a reactive monomer.

Provides excellent cohesion and adhesion.

3. Electronics & Optics

· Optical fiber coatings: As coating materials, providing high hardness, good tensile modulus, and water resistance.

· Optical disc protective layers: Excellent adhesion and scratch resistance on fine-textured surfaces.

· Microfluidic devices: Used to construct transparent, inert chip materials. High transparency, inertness, and tunable mechanical properties.

4. Plastic and Resin Modification

· Protective coatings for engineering plastics (PC, PP, etc.).

· Flow improver for powder coatings: Enhances melt flow leveling.

· Production of thermoplastic acrylic resins with high glass transition temperature (Tg).

Improves hardness, alcohol resistance, and heat resistance while maintaining flexibility and adhesion.

Description

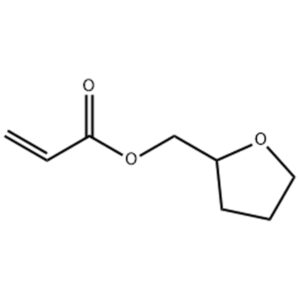

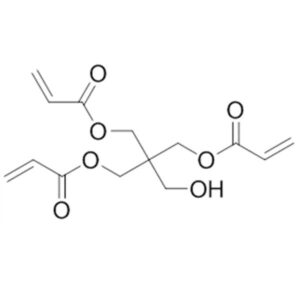

IBOA Monomer / Isobornyl acrylate CAS 5888-33-5

| Characteristic |

IBOA |

| Appearance |

Clear transparent |

| Formula Weight |

208 |

| Density g/ml |

0.984 |

| Refractive Index( 25℃ ) |

1.5040 |

| Viscosity()mPa.s |

7.5 |

| Closed Flash Point℃ |

93 |

| Glass Transition Temperature(Tg) ℃ |

90~100 |

| Surface Tension mN/m |

30 |

| Color (Pt-Co) |

≤30 |

| Ester content % |

≥98 |

| Moisture Content % |

≤0.2 |

| Polymer Content % |

/ |

| Inhibitor Content ppm |

100 |

IBOA Monomer USAGE

1. IBOA/IBXA has relatively high reactivity, weather resistance, low shrinkage, water resistance, chemical resistance; used in UV coatings (inks), adhesives, screen inks, photosensitive resins, photoresists.

2. Used in radiate curing coating (printing ink) as active diluents, it may effectively reduce the viscosity of the coating (printing ink), improve the performance of construction, and enhance leveling properties.

3. Usded as the active diluents of the epoxy-acrylic oligomer, it may reduce internal stress and volume shrinkage of the coating, thus improving the character index of radiation curing coating such as adhesion, volume shrinkage, anti-impact, mar resistance, weather resistance, and it won’t lose hardness and flexibility in its coating.

4. Used in protective coating of discs, it will attach extremely close with the surface of the texture on the disc. Moreover, has extremely enhances mar resistance and coating performance, and very distinctly improves the gloss of film.

5. Because IBOA has all sorts of merits (as listed above), it has been widely used in domains as active diluents of radiation curing coating, such as gloss varnish for metal, glass flexibility plastic film, engineering plastics as well as optical fiber coating, and has been simultaneously used in some special printing inks like outdoors spurt ink & news printing ink on thin-film of polyethylene.

1. Isobornyl acrylate is used in adhesives and special coatings, with high activity, high hardness and low shrinkage. Using Isobornyl acrylate as a reactive diluent for radiation curable coatings (inks) can effectively reduce the viscosity of the coatings (inks), improve construction performance, and improve the leveling of the coating.

2. Using Isobornyl acrylate as the reactive diluent of epoxy acrylic oligomer can significantly reduce the internal stress of the coating and reduce the volume shrinkage of the coating, thereby significantly improving the adhesion, shrinkage and impact resistance of the radiation cured coating Performance indicators such as resistance, scratch resistance and weather resistance, without reducing its hardness and flexibility.

3. If Isobornyl acrylate is used on the protective coating of optical discs, it has excellent adhesion and scratch resistance to the surface of fine lines, and has excellent coating properties and significantly improves the gloss of the coating film. Therefore, Isobornyl acrylate as a reactive diluent for radiation curing coatings has been widely used in metal finishing, glass flexible plastic film, engineering plastics and optical fiber coatings and other fields. At the same time, it is used in some special printing inks such as outdoor inkjet, polyethylene film and other materials. Used in the printing ink on the above.

4. Isobornyl acrylate is suitable for the manufacture of high Tg thermoplastic acrylic resin. Its products have high hardness, high alcohol resistance and heat resistance. And has good flexibility. Adhesion, moisture resistance, and weather resistance. It is a new type of acrylate polymer monomer with very characteristic structure. It is suitable for manufacturing soft plastic film coatings such as PET, PE, PP, and engineering plastic parts such as PE, PP, PC, etc. Decorative protective coating.

The table is the data table of the relative stress and volume shrinkage of the photocurable coating and the substrate when using different reactive diluents

| reactive diluent |

functionality |

Relative internal stress n |

Volume shrinkage n% |

| TMPTA |

3 |

1.42 |

16.06 |

| HDDA |

2 |

1.11 |

13.33 |

| NPGDA |

2 |

|

13.86 |

| CHA |

1 |

1.07 |

|

| IBOA |

1 |

0.88 |

8.24 |

IBOA Packaging and Shipping:

Packing: 25kg/drum or 200 kg/drum

Delivery: with in 5-7 working days.

IBOA Storage:

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Corey Yonng –

The delivery is very fast and quality is good.We are very satisfied.