Photoinitiator 379 Application scenarios

1. Graphic Arts/Printing & Packaging

UV-curable inks and varnishes (coatings) for substrates including paper, metal, and plastic.

Particularly suitable for color systems, offering excellent yellowing resistance and fast curing speeds.

2. Electronics/Photoresist

Photoresists and solder mask inks for printed circuit boards (PCBs), plus printing plate production.

High photosensitivity enables curing of intricate patterns with good thermal stability.

3. Inkjet/3D Printing

UV inkjet printing and UV 3D printing materials (e.g., resins).

Excellent solubility and high formulation compatibility, suitable for manufacturing high-precision components.

4. Other Curing Technologies

UV LED curing systems.

Suitable for new environmentally friendly, energy-efficient UV LED light source curing processes.

🌟 Core Performance & Advantages

High-Efficiency & Deep Curing:

High photoactivity enables deep-penetrating polymerization, ideal for thick coatings or pigmented systems.

Superior Solubility and Compatibility:

Outperforms comparable products (e.g., Omnirad 369) in solubility across various resins and monomers, simplifying formulation.

Low Odor and Anti-Yellowing:

Low volatility and minimal odor. Cured products exhibit stable color retention with minimal yellowing.

Description

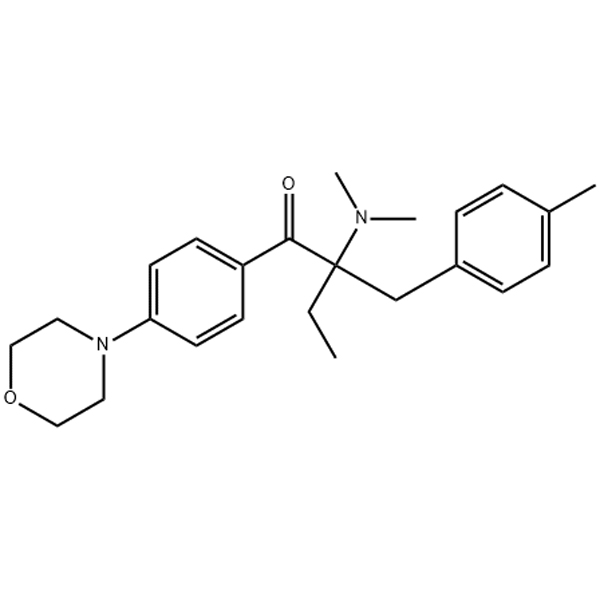

Photoinitiator 379 / irgacure 379 / Omnirad 379 CAS 119344-86-4

Chemial Name: 2-Dimethylamino-2-(4-methyl-benzyl)-1-(4-morpholin-4-yl-phenyl)-butan-1-one

Synonym: 379;Photoinitiator 379;Omnirad 379

CAS No: 119344-86-4

Molecular Formula: C24H32N2O2

General Information:

379 belongs to α-aminoketone derivatives, which has good thermal stability, long storage period, good solubility, light color, good anti-yellowing performance, fast light curing speed, and good deep curing performance.

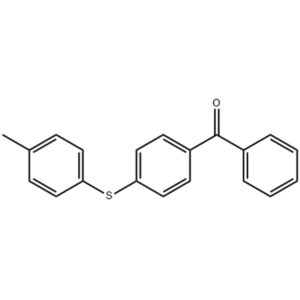

In the photopolymerization imaging system, it is a substance that is directly sensitive to light and promotes the polymerization of monomers into polymer compounds. α-Aminoketone derivatives are an important class of photoinitiators, and 379 is one of them. It has been widely used in the field of UV curing, and is widely used in photocurable coatings, inks, photoresist Etching and other fields.

Specification:

| Appearance |

Slightly yellow powder |

| Purity |

≥99% |

| Volatiles |

≤0.3% |

| Melting point |

82-87°C |

Usage:

The high efficiency of photoinitiator 379 is like a “lightning attack” in a chemical reaction. When exposed to ultraviolet light, it can quickly and massively produce free radicals, a process that is like an efficient chain reaction. From a chemical kinetic point of view, this ability to efficiently produce free radicals allows the polymerization reaction to proceed quickly and completely, greatly reducing the curing time and improving production efficiency. This is undoubtedly a key factor in reducing costs and increasing production for mass production.

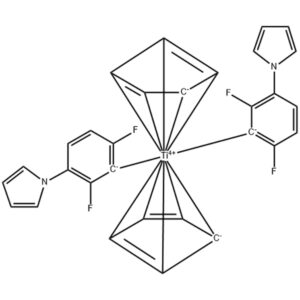

Its broad-spectrum response is like a “detector” with a wide field of view. The broad absorption spectrum in the ultraviolet region means that it can “cooperate” with various ultraviolet light sources. Whether it is a traditional mercury lamp ultraviolet light source or a new LED ultraviolet light source, photoinitiator 379 can adapt. This provides great flexibility in the selection of equipment for the production process. Companies can choose the most suitable ultraviolet light source according to their own needs and cost considerations, without worrying about the compatibility of the photoinitiator.

Good thermal stability is another advantage of photoinitiator 379. In high-temperature processing environments, it is like a tough warrior, not losing its activity due to high temperatures. In some processes that require high-temperature treatment, such as high-temperature baking after UV coating on certain special metal surfaces to enhance adhesion, photoinitiator 379 can still function stably to ensure the curing quality of the coating.

Low migration characteristics act as a stable “anchor” to ensure the long-term durability of cured products. In many products with stringent quality requirements, such as UV coatings for food packaging materials, if the photoinitiator migrates into the food, it may pose a safety risk. However, the low migration characteristics of photoinitiator 379 eliminate this concern, making the cured product stable and safe over time.

In addition, its low odor makes photoinitiator 379 stand out in scenarios where environmental and human health requirements are high. In the field of interior paints, people are very sensitive to odors. For example, in hospitals, schools, homes and other places, using low-odor formulations containing photoinitiator 379 not only allows for quick renovation and maintenance, but also provides a comfortable and healthy environment. According to a study on indoor air quality, the volatile organic compound (VOC) content in indoor spaces with low-odor paints is significantly lower than that in spaces with traditional paints, which further proves the important role of photoinitiator 379 in improving the indoor environment.

Compared to 369, 379 differentiates especially due to its substantially improved solubility which allows its use for applications in which 369 is at the solubility limit or couldn’t be used at all due to the limited solubility.

Recommended dosage:

- Offset inks : 2 – 4 % 369

- Screen inks: 2 – 4 % 369 + 1 – 3 % 184

- Pigmented coatings: 1 – 4 % 369

- Photopolymers for imaging applications: 0.5 – 5 % 369

Package:

20kg/carton.

Storage:

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Reviews

There are no reviews yet.