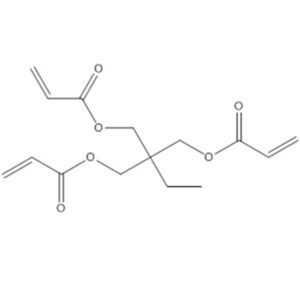

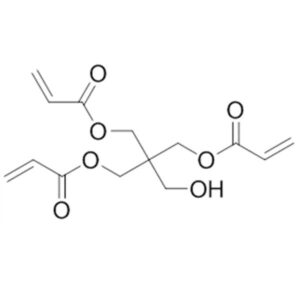

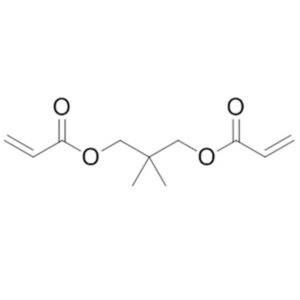

GPTA ( G3POTA ) Monomer Application scenarios

1. UV-Curable Coatings

Serves as an active diluent to reduce system viscosity while participating in curing and crosslinking. The cured coating exhibits high hardness, high gloss, excellent adhesion, and abrasion resistance. It is commonly used as a topcoat or protective coating on substrates such as metal, plastic, and paper.

2. UV-Curable Inks and Printing

Used in formulating UV inks, particularly in applications requiring good pigment wetting, rapid curing, and high print quality, such as offset printing. Commercial resin products (e.g., EBECRYL® 444) incorporate it as a key component.

3. 3D Printing and Advanced Materials

As a primary component of photosensitive resins, it is used in 3D printing technologies like Stereolithography (SLA) or Digital Light Processing (DLP). Its multifunctional properties facilitate the formation of dense, robust polymer networks, enhancing the strength and precision of printed parts.

4. Adhesives

Used in formulating UV-curable adhesives, enabling curing within seconds while delivering high bond strength and environmental resistance. (General applications based on its curing mechanism)

🔬 Other Potential and Research-Grade Applications

Beyond these established industrial uses, related research and literature suggest additional potential applications based on its chemical structure:

Tissue Engineering & Biomaterials: Studies indicate that structurally similar glycidyl acrylate derivatives can be used to fabricate biocompatible polymer scaffolds, showing potential in tissue engineering.

Organic-Inorganic Hybrid Materials: Literature mentions GPTA’s use in sol-gel processes to prepare rigid, microporous silica materials, which may serve specialized fields requiring optical transparency.

💡 Usage Considerations

When considering GPTA, note the following:

Product Specifications: Viscosity, acid value, and polymerization inhibitor content may vary across suppliers. Select based on specific formulation requirements.

Operational Safety: Although some sources indicate “low skin irritation,” as an acrylic monomer, protective gear (gloves, goggles) must be worn during handling, and ensure adequate workplace ventilation.

Storage Conditions: Store at room temperature away from light, and observe the product’s shelf life.

Sylvia Jennings –

excellent service and friendly staff. Great products