EOEOEA Monomer Application scenarios

1. UV-curable coatings, inks, and adhesives

Acts as an active diluent to reduce system viscosity and improve workability; imparts flexibility, high adhesion, low shrinkage, and weather resistance to cured coatings.

2. Electronics and precision processing

Serves as a copolymerizable monomer in photoresist formulations, where its hydrophilic properties help regulate polymer solubility in developer solutions.

3. Biomedical Materials

Used to synthesize highly absorbent hydrogels for drug-release carriers and tissue engineering scaffolds.

4. Polymer Modification

As a copolymerizable monomer, it synthesizes or modifies various polymers to introduce special functions like hydrophilicity, thermoresponsiveness, and self-healing capabilities.

🖌️ Core Industrial Applications Explained

It plays a pivotal role in the following traditional industrial sectors:

Radiation-Curable Materials: This is EOEOEA’s primary application. In UV- or electron-beam-curable coatings, inks (including solder mask inks), and adhesive formulations, it effectively dilutes resins while reacting to form part of the polymer network. This significantly enhances adhesion to substrates like wood, plastic, and paper while reducing curing shrinkage.

Specialty Polymer Synthesis: As a functional monomer, it synthesizes acrylic resins with tailored properties—such as protective coatings for optical fibers that enhance thermal stability.

🔬 Cutting-Edge & Research Applications

In more advanced technological fields, EOEOEA research applications demonstrate immense potential:

Biomedical Hydrogels:

Its excellent biocompatibility and hydrophilicity make it an ideal monomer for hydrogel preparation. Such hydrogels can load drugs for controlled release or serve as 3D scaffolds supporting cell growth for tissue repair.

Advanced Material Development:

Research is exploring its use in developing thermoresponsive materials (changing solubility or state with temperature), self-healing materials (repairing damage autonomously), and fabricating micro/nano-scale 3D hydrogel structures via two-photon polymerization for biochips and microdevices.

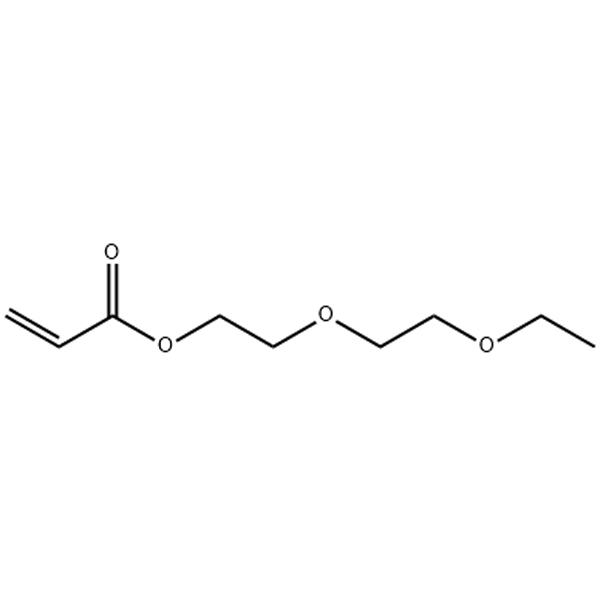

Description

EOEOEA Monomer / 2-(2-Ethoxyethoxy)ethyl acrylate CAS 7328-17-8

| Appearance |

Transparent liquid |

| Polymerization inhibitor, ppm |

≤200 MEHQ |

| Moisture, wt.% |

0.2 |

| Acid value, mgKOH/g- |

0.5 |

| Color, APHA |

≤100 |

| Density , 25℃ |

1.08~1.11 |

| Viscosity , CPS.25℃ |

3~8 |

| Refractive index |

1.436 |

| Surface Tension, dynes/cm |

29.7 |

| EOEOEA Tg,℃ |

-56 |

In the broad field of light-curing materials, EOEOEA stands out as an acrylate monomer that plays an important role in the UV polymerization of various unsaturated systems, such as UV paints, UV inks and UV adhesives.

When analyzed in depth, its high flexibility is remarkable. In contrast to many conventional monomers, EOEOEA is a soft “elf” that imparts unique flexible qualities to materials. For example, in the encapsulation coating of some flexible electronic products, this high flexibility prevents cracks in the material due to bending, thus ensuring the stability and service life of the electronic components.

In addition, the dilution ability of EOEOEA should not be underestimated. When and TPGDA, DPGDA, TMPTA and other traditional monomers in the same system, it is like a powerful “diluent key”, can more efficiently adjust the viscosity of the system. To a high-end UV ink formulation research and development, for example, after adding EOEOEA, the fluidity of the ink has been greatly improved, making the printing process smoother, the uniformity and saturation of the color has also been enhanced.

In addition, its good adhesion is also a major highlight, especially in the face of plastic materials, EOEOEA is like a loyal “adhesion guard”. Historically, in the early development of surface coating technology for plastics, adhesion has always been a problem, and many monomers are difficult to achieve the desired effect. The emergence of EOEOEA has brought a new dawn for plastic surface treatment. In the modern decorative and protective coating process of plastic products, it can be tightly adhered to the plastic surface, whether in the daily wear and tear or in the erosion of complex environments, can ensure that the integrity and durability of the coating, greatly extending the aesthetic and practical cycle of plastic products.

Assuming that in the field of new material research and development in the future, with the continuous progress of science and technology, if we compound EOEOEA with some emerging nano-materials, will it be possible to create a kind of super-materials with super adhesion, high flexibility and special functions (such as self-repairing, anti-bacteria, etc.)? This is undoubtedly a new direction worthy of in-depth exploration and research, and once successful, it will lead to a new change in the application of materials in many fields such as aerospace, biomedical, and high-end manufacturing.

EOEOEA Applications

Wood coatings, PVC coatings, plastic coatings, metal coatings, offset printing inks, flexographic printing, screen printing, varnish.adhesives.

EOEOEA Packaging and Shipping

Packing:25kg/drum or 200 kg/drum

Delivery:with in 5-7 working days.

EOEOEA Storage

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Reviews

There are no reviews yet.