DPGDA Monomer Application scenarios

1. Coatings

Wood coatings (flooring, furniture topcoats); plastic coatings (mobile phone casings, appliance panels); metal coatings

Reduces system viscosity, enhances flow and surface gloss, balances cured film hardness and flexibility.

2. Inks

Printing inks (offset, flexographic, screen printing inks); electronic inks (PCB solder mask inks, touchscreen inks)

High reactivity ensures rapid curing, excellent pigment wetting, and abrasion resistance.

3. Adhesives

UV-curable adhesives (optical components, glass/plastic bonding); pressure-sensitive adhesives

Rapidly cures to form a cross-linked network structure, enhancing bond strength, tack, and weather resistance.

4. 3D Printing

Active diluents for photopolymer resins (SLA/DLP)

Adjusts resin viscosity, participates in photopolymerization, and influences part hardness, toughness, and dimensional accuracy.

5. Other Applications

Electronic encapsulation materials (LED packaging, semiconductor protective coatings); UV-curable nail products; Crosslinking agent for expandable microspheres

Used as a crosslinking agent (e.g., for expandable microspheres), providing smooth spherical surfaces and optimal crosslinking density.

Description

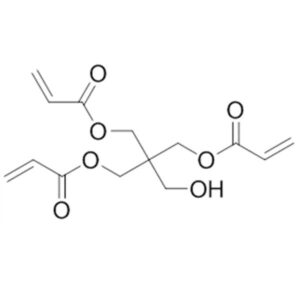

DPGDA Monomer / Dipropylene Glycol Dienoate CAS 57472-68-1

| Appearance |

Clear liquid |

| Acid Value (mgKOH/g) |

≤0.5 |

| Viscosity @25℃,cps |

7-13 |

| Color(APHA) |

≤60 |

| Moisture(% Karl Fischer) |

≤0.2 |

| Inhibitor(MEHQ ppm) |

400-600 |

| Specific Gravity @25℃ |

1.04-1.10 |

| Refractive Index @25℃ |

1.445-1.455 |

| Solvent(GC %) |

≤0.2 |

DPGDA Monomer / Dipropylene Glycol Dienoate Applications:

1. DPGDA (Dipropylene Glycol Diallyl Acid) DPGDA is no ordinary compound, it belongs to the family of bifunctional active diluents. When it meets a source of free radicals, a marvelous polymerization reaction is initiated and, like a carefully choreographed chemical dance, the molecules are connected to each other to form completely new structures.

2. In the realm of coatings and inks, DPGDA is undoubtedly a shining star. Taking flexibility as an example, in the surface coating of materials that require frequent bending or stretching, such as the shell coating of foldable electronic products and the ink printing layer of flexible packaging materials, DPGDA can ensure that the coating will not be easily broken or peeled off during the deformation process. In the field of automobile refinishing paint, vehicle surfaces are often exposed to various external impacts and environmental erosion, and the flexibility given by DPGDA can effectively prevent the paint from cracking and greatly extend the service life of the coating. In terms of adhesion, in metal surface treatment, such as the coating of aluminum alloy doors and windows, DPGDA can make the coating closely adhere to the metal surface, forming a uniform and solid protective film, effectively resisting the interference of external factors. As for moisture resistance, in food packaging inks and coatings application scenarios, DPGDA is able to act like a loyal guard to block the intrusion of moisture and maintain the freshness and quality of the food inside the package.

3. When focusing on the field of UV inks and UV coatings, DPGDA’s performance is even more remarkable. In high-end printing products, such as fine art albums and high-quality commercial posters, the DPGDA component in UV inks enables the printing of vivid and long-lasting colors, as well as good abrasion and weather resistance. In UV coating applications for the furniture manufacturing industry, DPGDA helps create a smooth, glossy and durable surface that not only enhances the aesthetics of the furniture, but also increases its resistance to moisture and abrasion.

4. The application areas of DPGDA monomer are still expanding. In radiation curing systems, it plays the dual role of active diluent and crosslinking agent. Compared with the traditional curing system, radiation curing has high efficiency, energy saving, environmental protection and other significant advantages. Take the manufacturing of electronic circuit boards as an example, DPGDA is involved in the radiation curing process to quickly form a stable insulating layer, which greatly improves production efficiency. In the field of resin cross-linking agent, DPGDA can interact with different types of resins to improve the performance of the resin. For example, in the epoxy resin system, it can enhance the flexibility and impact resistance of the resin, making it more widely used in aerospace, high-end equipment manufacturing and other fields. In terms of plastic and rubber modifiers, DPGDA is like a magical wizard, able to transform ordinary plastics and rubber into materials with special properties. In the manufacture of high-performance tires, the rubber materials added with DPGDA modifiers have significantly improved wear resistance, aging resistance and grip, providing a strong guarantee for the safety and performance of automobile driving.

DPGDA Monomer / Dipropylene Glycol Dienoate Packaging and Shipping:

Packing:100G; 25kg/drum or 200 kg/drum

Delivery:with in 5-7 working days.

DPGDA Monomer / Dipropylene Glycol Dienoate Storage:

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Lucas Wilson –

I’m thoroughly impressed with the product’s quality and the efficiency of the delivery. The entire process was smooth and hassle-free. Highly recommend!