Description

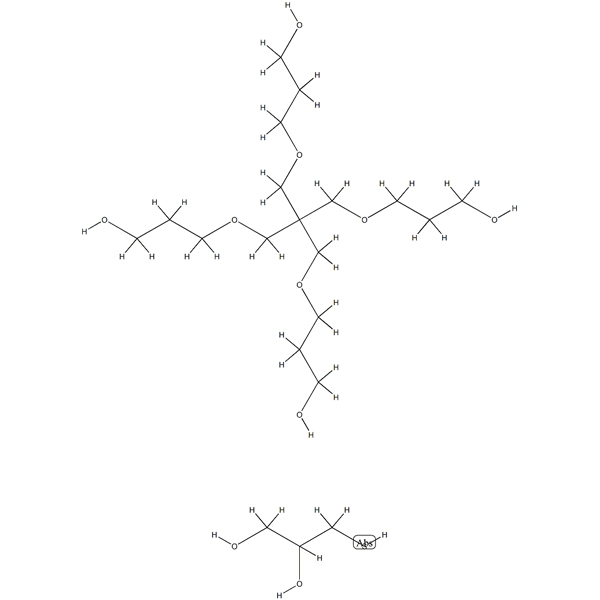

PM839 CAS 72244-98-5

| Appearance | Colorless transparent liquid |

| Viscosity (25℃) , mPas | 12000~14000 |

| APHA Color | ≤20 |

PM839 Usage:

In the field of material science, PM839 has emerged as a low-temperature fast curing agent for epoxy resins. Its appearance is pure and colorless, or a transparent liquid with a hint of yellowish color. Its viscosity ranges from 12,000 to 14,000 mPa-s at room temperature, i.e., 25°C. This viscosity characteristic makes it useful in a wide range of application scenarios. Its sulfhydryl content is impressive at ≥12 and its coloration is controlled at ≤20, which ensures both performance and good appearance in use.

In terms of practical applications, PM839 is frequently seen in various industrial and electronic fields. In the case of 5-minute AB glue, for example, it can achieve efficient bonding results in a very short time, which meets the needs of rapid production. In the field of electronic adhesives, it provides a reliable guarantee for the fixing and encapsulation of electronic components. In the application of metal epoxy putty, it can effectively fill the tiny gaps on the metal surface and enhance the stability and durability of the metal structure. In the production of electronic thermal conductive adhesive, PM839 not only has good bonding performance, but also can realize efficient heat conduction, to ensure the stability of electronic equipment in the process of operation. In the field of anticorrosive coatings, it provides a strong protective barrier for metal surfaces against the erosion of the external environment.

The field of silicon rod cutting adhesive deserves special mention. Silicon rod cutting, as a key link in the photovoltaic industry, requires high performance of cutting adhesives, and PM839 silicon rod cutting adhesive shows excellent bonding strength and flexibility after curing. From the perspective of historical development, the early silicon rod cutting adhesive due to poor performance, resulting in silicon rod cutting process often appear to fall, edge chips and cracks and other problems, seriously affecting the yield of silicon rod cutting. The appearance of PM839 has greatly improved this situation. For example, in the production line of a large photovoltaic enterprise, after the use of PM839 cutting adhesive, the yield of silicon bar cutting from the original 70% to more than 90%, which not only improves the production efficiency, but also reduces the production cost. Once the silicon rods have been cut, the silicon wafers coated with the adhesive can be quickly and easily separated by immersing them in warm water, which also facilitates large-scale industrial production.

The photovoltaic industry is in a golden age of growth as the global demand for clean energy grows. According to relevant data, the annual growth rate of the global photovoltaic industry has reached more than 20% in the past decade. In this development trend, the fine degree of silicon rod cutting requirements are also rising, which will undoubtedly promote the market demand for silicon rod cutting adhesive shows a rapid growth trend. According to the forecast of market research institutions, in the next five years, the market size of silicone rod cutting adhesive is expected to realize double growth.

In addition, PM839 also plays an important role in the packaging field of electronic and electrical production. As a key process in the production of electronic and electrical appliances, the quality of packaging is directly related to the final quality and service life of the product. In the packaging process of electronic components, packaging adhesive bears the important responsibility of protecting electronic components. From the scientific principle, it can effectively prevent the intrusion of moisture, avoiding the electronic components short-circuit or damage due to moisture. At the same time, it can also block dust and harmful gases to prevent these impurities from corroding electronic equipment or circuit boards. For example, in some electronic enterprises in coastal areas, due to the high humidity of the air, if high-quality packaging adhesives are not used, the failure rate of electronic components will be significantly higher. In addition, packaging adhesives can also slow down or offset the effects of external forces and vibrations on electronic components through their own cushioning effect, thus greatly improving the stability of electronic equipment. As the demand for smart phones, smart homes and other electronic and electrical products continues to climb globally, China, as the world’s largest electronics production and consumption market, is also expanding its market size. According to statistics, China’s electronics market has grown at an annual rate of about 15% over the past five years, which will further drive the steady growth in demand for adhesives for electrical and electronic products.

PM839 Package

25kg/drum or 220 kg/drum

PM839 Storage:

Being kept in dry, clean warehouse with well ventilation.

Avoid exposing to light and heating.

Protecting the product from leakage, rain and insolation during transportation.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

| Polythiol/Polymercaptan | ||

| CHLUMICRYL®DMES Monomer | Bis(2-mercaptoethyl) sulfide | 3570-55-6 |

| CHLUMICRYL® DMPT Monomer | THIOCURE DMPT | 131538-00-6 |

| CHLUMICRYL® PETMP Monomer | 7575-23-7 | |

| CHLUMICRYL® PM839 Monomer | Polyoxy(methyl-1,2-ethanediyl) | 72244-98-5 |

| Monofunctional Monomer | ||

| CHLUMICRYL® HEMA Monomer | 2-hydroxyethyl methacrylate | 868-77-9 |

| CHLUMICRYL® HPMA Monomer | 2-Hydroxypropyl methacrylate | 27813-02-1 |

| CHLUMICRYL® THFA Monomer | Tetrahydrofurfuryl acrylate | 2399-48-6 |

| CHLUMICRYL® HDCPA Monomer | Hydrogenated dicyclopentenyl acrylate | 79637-74-4 |

| CHLUMICRYL® DCPMA Monomer | Dihydrodicyclopentadienyl methacrylate | 30798-39-1 |

| CHLUMICRYL® DCPA Monomer | Dihydrodicyclopentadienyl Acrylate | 12542-30-2 |

| CHLUMICRYL® DCPEMA Monomer | Dicyclopentenyloxyethyl Methacrylate | 68586-19-6 |

| CHLUMICRYL® DCPEOA Monomer | Dicyclopentenyloxyethyl Acrylate | 65983-31-5 |

| CHLUMICRYL® NP-4EA Monomer | (4) ethoxylated nonylphenol | 50974-47-5 |

| LA Monomer | Lauryl acrylate / Dodecyl acrylate | 2156-97-0 |

| CHLUMICRYL® THFMA Monomer | Tetrahydrofurfuryl methacrylate | 2455-24-5 |

| CHLUMICRYL® PHEA Monomer | 2-PHENOXYETHYL ACRYLATE | 48145-04-6 |

| CHLUMICRYL® LMA Monomer | Lauryl methacrylate | 142-90-5 |

| CHLUMICRYL® IDA Monomer | Isodecyl acrylate | 1330-61-6 |

| CHLUMICRYL® IBOMA Monomer | Isobornyl methacrylate | 7534-94-3 |

| CHLUMICRYL® IBOA Monomer | Isobornyl acrylate | 5888-33-5 |

| CHLUMICRYL® EOEOEA Monomer | 2-(2-Ethoxyethoxy)ethyl acrylate | 7328-17-8 |

| Multifunctional monomer | ||

| CHLUMICRYL® DPHA Monomer | 29570-58-9 | |

| CHLUMICRYL® DI-TMPTA Monomer | DI(TRIMETHYLOLPROPANE) TETRAACRYLATE | 94108-97-1 |

| Acrylamide monomer | ||

| CHLUMICRYL® ACMO Monomer | 4-acryloylmorpholine | 5117-12-4 |

| Di-functional Monomer | ||

| CHLUMICRYL® PEGDMA Monomer | Poly(ethylene glycol) dimethacrylate | 25852-47-5 |

| CHLUMICRYL® TPGDA Monomer | Tripropylene glycol diacrylate | 42978-66-5 |

| CHLUMICRYL® TEGDMA Monomer | Triethylene glycol dimethacrylate | 109-16-0 |

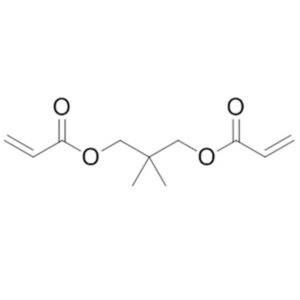

| CHLUMICRYL® PO2-NPGDA Monomer | Propoxylate neopentylene glycol diacrylate | 84170-74-1 |

| CHLUMICRYL® PEGDA Monomer | Polyethylene Glycol Diacrylate | 26570-48-9 |

| CHLUMICRYL® PDDA Monomer | Phthalate diethylene glycol diacrylate | |

| CHLUMICRYL® NPGDA Monomer | Neopentyl glycol diacrylate | 2223-82-7 |

| CHLUMICRYL® HDDA Monomer | Hexamethylene Diacrylate | 13048-33-4 |

| CHLUMICRYL® EO4-BPADA Monomer | ETHOXYLATED (4) BISPHENOL A DIACRYLATE | 64401-02-1 |

| CHLUMICRYL® EO10-BPADA Monomer | ETHOXYLATED (10) BISPHENOL A DIACRYLATE | 64401-02-1 |

| CHLUMICRYL® EGDMA Monomer | Ethylene glycol dimethacrylate | 97-90-5 |

| CHLUMICRYL® DPGDA Monomer | Dipropylene Glycol Dienoate | 57472-68-1 |

| CHLUMICRYL® Bis-GMA Monomer | Bisphenol A Glycidyl Methacrylate | 1565-94-2 |

| Trifunctional Monomer | ||

| CHLUMICRYL® TMPTMA Monomer | Trimethylolpropane trimethacrylate | 3290-92-4 |

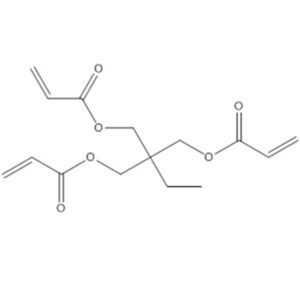

| CHLUMICRYL® TMPTA Monomer | Trimethylolpropane triacrylate | 15625-89-5 |

| CHLUMICRYL® PETA Monomer | 3524-68-3 | |

| CHLUMICRYL® GPTA ( G3POTA ) Monomer | GLYCERYL PROPOXY TRIACRYLATE | 52408-84-1 |

| CHLUMICRYL® EO3-TMPTA Monomer | Ethoxylated trimethylolpropane triacrylate | 28961-43-5 |

| Photoresist Monomer | ||

| CHLUMICRYL® IPAMA Monomer | 2-isopropyl-2-adamantyl methacrylate | 297156-50-4 |

| CHLUMICRYL® ECPMA Monomer | 1-Ethylcyclopentyl Methacrylate | 266308-58-1 |

| CHLUMICRYL® ADAMA Monomer | 1-Adamantyl Methacrylate | 16887-36-8 |

| Methacrylates monomer | ||

| CHLUMICRYL® TBAEMA Monomer | 2-(Tert-butylamino)ethyl methacrylate | 3775-90-4 |

| CHLUMICRYL® NBMA Monomer | n-Butyl methacrylate | 97-88-1 |

| CHLUMICRYL® MEMA Monomer | 2-Methoxyethyl Methacrylate | 6976-93-8 |

| CHLUMICRYL® i-BMA Monomer | Isobutyl methacrylate | 97-86-9 |

| CHLUMICRYL® EHMA Monomer | 2-Ethylhexyl methacrylate | 688-84-6 |

| CHLUMICRYL® EGDMP Monomer | Ethylene glycol Bis(3-mercaptopropionate) | 22504-50-3 |

| CHLUMICRYL® EEMA Monomer | 2-ethoxyethyl 2-methylprop-2-enoate | 2370-63-0 |

| CHLUMICRYL® DMAEMA Monomer | N,M-Dimethylaminoethyl methacrylate | 2867-47-2 |

| CHLUMICRYL® DEAM Monomer | Diethylaminoethyl methacrylate | 105-16-8 |

| CHLUMICRYL® CHMA Monomer | Cyclohexyl methacrylate | 101-43-9 |

| CHLUMICRYL® BZMA Monomer | Benzyl methacrylate | 2495-37-6 |

| CHLUMICRYL® BDDMP Monomer | 1,4-Butanediol Di(3-mercaptopropionate) | 92140-97-1 |

| CHLUMICRYL® BDDMA Monomer | 1,4-Butanedioldimethacrylate | 2082-81-7 |

| CHLUMICRYL® AMA Monomer | Allyl methacrylate | 96-05-9 |

| CHLUMICRYL® AAEM Monomer | Acetylacetoxyethyl methacrylate | 21282-97-3 |

| Acrylates Monomer | ||

| CHLUMICRYL® IBA Monomer | Isobutyl acrylate | 106-63-8 |

| CHLUMICRYL® EMA Monomer | Ethyl methacrylate | 97-63-2 |

| CHLUMICRYL® DMAEA Monomer | Dimethylaminoethyl acrylate | 2439-35-2 |

| CHLUMICRYL® DEAEA Monomer | 2-(diethylamino)ethyl prop-2-enoate | 2426-54-2 |

| CHLUMICRYL® CHA Monomer | cyclohexyl prop-2-enoate | 3066-71-5 |

| CHLUMICRYL® BZA Monomer | benzyl prop-2-enoate | 2495-35-4 |

| Other Monomer | ||

| CHLUMICRYL® MCPMA Monomer | 1-Methylcyclopentyl Methacrylate | 178889-45-7 |

| CHLUMICRYL® TMPMP Monomer | Trimethylolpropane Tris(3-mercaptopropionate) | 33007-83-9 |

| CHLUMICRYL® CTFA Monomer | Cyclic Trimethylopropane Formal Acrylate | 66492-51-1 |

| CHLUMICRYL® HPHPDA Monomer | 30145-51-8 | |

| CHLUMICRYL® MPEG Monomer | 26915-72-0 | |

Xavier Thompson –

Wonderful experience! The service was top-notch, the product quality exceeded my expectations.