Description

AMA Monomer / Allyl methacrylate CAS 96-05-9

| Item | Specification |

| CAS No | 96-05-9 |

| Color(Pt-Co),Hazen | 20 |

| Pueity,% ≥ | 99.5 |

| Water content,% ≤ | 0.1 |

| VAcidity(as methacrylic acid),% ≤ | 0.03 |

Allyl methacrylate is an important cross-linking agent that provides second-stage effective cross-linking of bifunctional groups with good pharmaceutical resistance, impact strength, adhesion, hardness and low shrinkage. It is used in dental materials, industrial paints, silicone intermediates, antiglare agents, optical polymers, elastomers and some vinyl and acrylate polymer systems.

Other Name:

Ageflex AMA;

Allylester kyseliny methakrylove;

allyl 2-methacrylate;

Allylmethacrylate;

Visomer AMA;

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

| Polythiol/Polymercaptan | ||

| CHLUMICRYL®DMES Monomer | Bis(2-mercaptoethyl) sulfide | 3570-55-6 |

| CHLUMICRYL® DMPT Monomer | THIOCURE DMPT | 131538-00-6 |

| CHLUMICRYL® PETMP Monomer | 7575-23-7 | |

| CHLUMICRYL® PM839 Monomer | Polyoxy(methyl-1,2-ethanediyl) | 72244-98-5 |

| Monofunctional Monomer | ||

| CHLUMICRYL® HEMA Monomer | 2-hydroxyethyl methacrylate | 868-77-9 |

| CHLUMICRYL® HPMA Monomer | 2-Hydroxypropyl methacrylate | 27813-02-1 |

| CHLUMICRYL® THFA Monomer | Tetrahydrofurfuryl acrylate | 2399-48-6 |

| CHLUMICRYL® HDCPA Monomer | Hydrogenated dicyclopentenyl acrylate | 79637-74-4 |

| CHLUMICRYL® DCPMA Monomer | Dihydrodicyclopentadienyl methacrylate | 30798-39-1 |

| CHLUMICRYL® DCPA Monomer | Dihydrodicyclopentadienyl Acrylate | 12542-30-2 |

| CHLUMICRYL® DCPEMA Monomer | Dicyclopentenyloxyethyl Methacrylate | 68586-19-6 |

| CHLUMICRYL® DCPEOA Monomer | Dicyclopentenyloxyethyl Acrylate | 65983-31-5 |

| CHLUMICRYL® NP-4EA Monomer | (4) ethoxylated nonylphenol | 50974-47-5 |

| LA Monomer | Lauryl acrylate / Dodecyl acrylate | 2156-97-0 |

| CHLUMICRYL® THFMA Monomer | Tetrahydrofurfuryl methacrylate | 2455-24-5 |

| CHLUMICRYL® PHEA Monomer | 2-PHENOXYETHYL ACRYLATE | 48145-04-6 |

| CHLUMICRYL® LMA Monomer | Lauryl methacrylate | 142-90-5 |

| CHLUMICRYL® IDA Monomer | Isodecyl acrylate | 1330-61-6 |

| CHLUMICRYL® IBOMA Monomer | Isobornyl methacrylate | 7534-94-3 |

| CHLUMICRYL® IBOA Monomer | Isobornyl acrylate | 5888-33-5 |

| CHLUMICRYL® EOEOEA Monomer | 2-(2-Ethoxyethoxy)ethyl acrylate | 7328-17-8 |

| Multifunctional monomer | ||

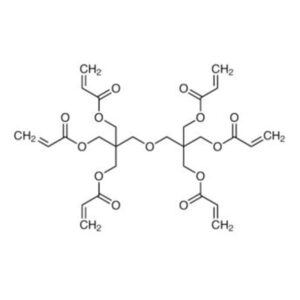

| CHLUMICRYL® DPHA Monomer | 29570-58-9 | |

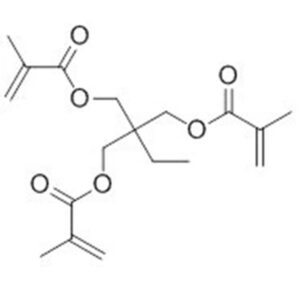

| CHLUMICRYL® DI-TMPTA Monomer | DI(TRIMETHYLOLPROPANE) TETRAACRYLATE | 94108-97-1 |

| Acrylamide monomer | ||

| CHLUMICRYL® ACMO Monomer | 4-acryloylmorpholine | 5117-12-4 |

| Di-functional Monomer | ||

| CHLUMICRYL® PEGDMA Monomer | Poly(ethylene glycol) dimethacrylate | 25852-47-5 |

| CHLUMICRYL® TPGDA Monomer | Tripropylene glycol diacrylate | 42978-66-5 |

| CHLUMICRYL® TEGDMA Monomer | Triethylene glycol dimethacrylate | 109-16-0 |

| CHLUMICRYL® PO2-NPGDA Monomer | Propoxylate neopentylene glycol diacrylate | 84170-74-1 |

| CHLUMICRYL® PEGDA Monomer | Polyethylene Glycol Diacrylate | 26570-48-9 |

| CHLUMICRYL® PDDA Monomer | Phthalate diethylene glycol diacrylate | |

| CHLUMICRYL® NPGDA Monomer | Neopentyl glycol diacrylate | 2223-82-7 |

| CHLUMICRYL® HDDA Monomer | Hexamethylene Diacrylate | 13048-33-4 |

| CHLUMICRYL® EO4-BPADA Monomer | ETHOXYLATED (4) BISPHENOL A DIACRYLATE | 64401-02-1 |

| CHLUMICRYL® EO10-BPADA Monomer | ETHOXYLATED (10) BISPHENOL A DIACRYLATE | 64401-02-1 |

| CHLUMICRYL® EGDMA Monomer | Ethylene glycol dimethacrylate | 97-90-5 |

| CHLUMICRYL® DPGDA Monomer | Dipropylene Glycol Dienoate | 57472-68-1 |

| CHLUMICRYL® Bis-GMA Monomer | Bisphenol A Glycidyl Methacrylate | 1565-94-2 |

| Trifunctional Monomer | ||

| CHLUMICRYL® TMPTMA Monomer | Trimethylolpropane trimethacrylate | 3290-92-4 |

| CHLUMICRYL® TMPTA Monomer | Trimethylolpropane triacrylate | 15625-89-5 |

| CHLUMICRYL® PETA Monomer | 3524-68-3 | |

| CHLUMICRYL® GPTA ( G3POTA ) Monomer | GLYCERYL PROPOXY TRIACRYLATE | 52408-84-1 |

| CHLUMICRYL® EO3-TMPTA Monomer | Ethoxylated trimethylolpropane triacrylate | 28961-43-5 |

| Photoresist Monomer | ||

| CHLUMICRYL® IPAMA Monomer | 2-isopropyl-2-adamantyl methacrylate | 297156-50-4 |

| CHLUMICRYL® ECPMA Monomer | 1-Ethylcyclopentyl Methacrylate | 266308-58-1 |

| CHLUMICRYL® ADAMA Monomer | 1-Adamantyl Methacrylate | 16887-36-8 |

| Methacrylates monomer | ||

| CHLUMICRYL® TBAEMA Monomer | 2-(Tert-butylamino)ethyl methacrylate | 3775-90-4 |

| CHLUMICRYL® NBMA Monomer | n-Butyl methacrylate | 97-88-1 |

| CHLUMICRYL® MEMA Monomer | 2-Methoxyethyl Methacrylate | 6976-93-8 |

| CHLUMICRYL® i-BMA Monomer | Isobutyl methacrylate | 97-86-9 |

| CHLUMICRYL® EHMA Monomer | 2-Ethylhexyl methacrylate | 688-84-6 |

| CHLUMICRYL® EGDMP Monomer | Ethylene glycol Bis(3-mercaptopropionate) | 22504-50-3 |

| CHLUMICRYL® EEMA Monomer | 2-ethoxyethyl 2-methylprop-2-enoate | 2370-63-0 |

| CHLUMICRYL® DMAEMA Monomer | N,M-Dimethylaminoethyl methacrylate | 2867-47-2 |

| CHLUMICRYL® DEAM Monomer | Diethylaminoethyl methacrylate | 105-16-8 |

| CHLUMICRYL® CHMA Monomer | Cyclohexyl methacrylate | 101-43-9 |

| CHLUMICRYL® BZMA Monomer | Benzyl methacrylate | 2495-37-6 |

| CHLUMICRYL® BDDMP Monomer | 1,4-Butanediol Di(3-mercaptopropionate) | 92140-97-1 |

| CHLUMICRYL® BDDMA Monomer | 1,4-Butanedioldimethacrylate | 2082-81-7 |

| CHLUMICRYL® AMA Monomer | Allyl methacrylate | 96-05-9 |

| CHLUMICRYL® AAEM Monomer | Acetylacetoxyethyl methacrylate | 21282-97-3 |

| Acrylates Monomer | ||

| CHLUMICRYL® IBA Monomer | Isobutyl acrylate | 106-63-8 |

| CHLUMICRYL® EMA Monomer | Ethyl methacrylate | 97-63-2 |

| CHLUMICRYL® DMAEA Monomer | Dimethylaminoethyl acrylate | 2439-35-2 |

| CHLUMICRYL® DEAEA Monomer | 2-(diethylamino)ethyl prop-2-enoate | 2426-54-2 |

| CHLUMICRYL® CHA Monomer | cyclohexyl prop-2-enoate | 3066-71-5 |

| CHLUMICRYL® BZA Monomer | benzyl prop-2-enoate | 2495-35-4 |

| Other Monomer | ||

| CHLUMICRYL® MCPMA Monomer | 1-Methylcyclopentyl Methacrylate | 178889-45-7 |

| CHLUMICRYL® TMPMP Monomer | Trimethylolpropane Tris(3-mercaptopropionate) | 33007-83-9 |

| CHLUMICRYL® CTFA Monomer | Cyclic Trimethylopropane Formal Acrylate | 66492-51-1 |

| CHLUMICRYL® HPHPDA Monomer | 30145-51-8 | |

| CHLUMICRYL® MPEG Monomer | 26915-72-0 | |

Alexander Lee –

From start to finish, the entire shopping experience was seamless. The product arrived well-packaged and in pristine condition. A definite five-star!