ACMO Monomer Application scenarios

1. UV-Curing Materials

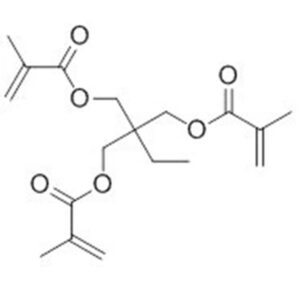

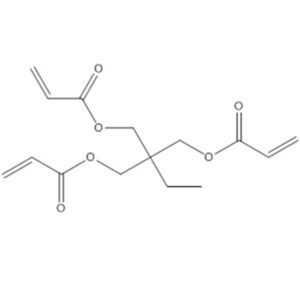

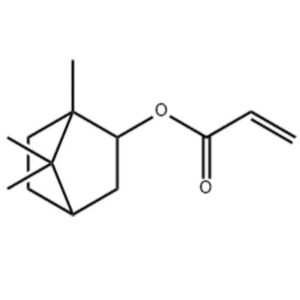

UV-curable coatings, inks, and 3D printing photopolymer resins.

Reactive diluent: Reduces system viscosity and participates in curing, resulting in low shrinkage and fast curing.

2. Adhesives

Pressure-sensitive adhesives, optical adhesives, protective films, etc.

Provides excellent adhesion while being low in irritation and odor.

3. Textile and Fiber Treatment

Used as a fiber treatment agent.

Improves fiber performance.

4. Water Treatment and Oilfield Exploration

Used in the preparation of flocculants and oilfield polymers.

As a water-soluble polymer monomer, it can replace toxic acrylamide products.

5. Medical and Biomaterials

Can be used to synthesize drugs and biomaterials.

Highly reactive, suitable for the synthesis of various compounds. It has been studied for applications in biomedical 3D printing (such as artificial blood vessels).

6. Daily Chemical Products

Cosmetics, personal care products.

Specific functions are not detailed, likely utilizing its mild properties.

💡 Core Performance and Safety Information

Understanding the following characteristics of ACMO can help you understand the reasons for its wide range of applications

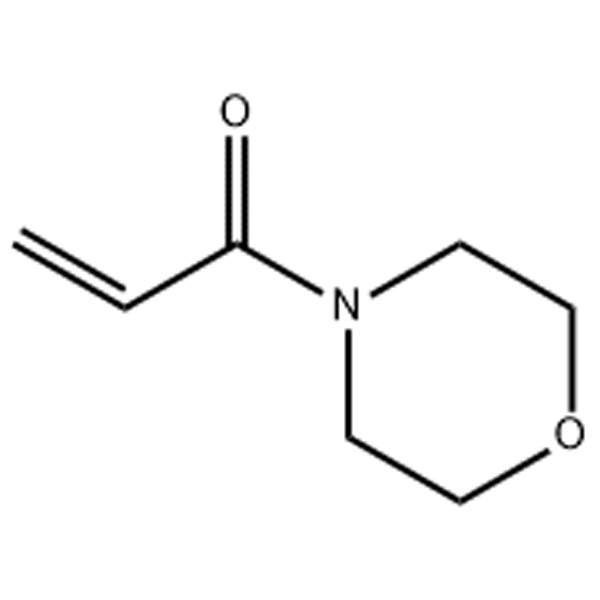

Core Characteristics: ACMO is a monofunctional acrylamide monomer with active chemical properties. The morpholine group in its molecular structure gives it both hydrophilicity and reactivity.

Performance Advantages: In practical applications, it is favored for its low viscosity, low odor, and low skin irritation. As a diluent, it imparts good flexibility, wear resistance, and chemical resistance to the cured product.

Description

ACMO Monomer / 4-acryloylmorpholine / Omnimer ACMO cas 5117-12-4

| Item |

Specification |

| Appearance |

Colorless or light yellow clear liquid |

| Assay |

≥98.0% |

| Color |

≤50APHA |

| Viscosity |

≤12cps(25℃) |

| Moisture |

≤0.3% |

ACMO Monomer / 4-Acryloylmorpholine Application

1. ACMO, as a heat-resistant functional monomer of great importance in the field of materials science, exhibits a number of remarkable qualities. In terms of skin irritation, its P.I.I. value is as low as 0.5, which means that its potential irritation to human skin is minimal, greatly guaranteeing its safety in relevant application scenarios. It is also worth mentioning that ACMO has a very low vapor pressure, which makes it virtually odorless during use, effectively avoiding the impact of bad odors from volatiles on the environment and the user, thus broadening its application scope, for example, in the field of interior decoration materials or personal care products that are sensitive to odors.

2. In practical applications, ACMO’s low viscosity combined with its fast curing advantage makes it an indispensable active diluent in UV-curable resins. Take the coating of electronic products as an example, ACMO can be quickly and uniformly dispersed in the resin system, curing rapidly under UV irradiation to form a tough and stable protective film, effectively improving the wear and corrosion resistance of the product, and meeting the demand for thin, light and durable coatings for electronic products.

3. In-depth exploration of the homopolymer of ACMO, its good dilution and solubility make it can be perfectly adapted with a variety of solvents. This property plays a key role in the coatings and inks industries. For example, in the development of waterborne coatings, ACMO homopolymers help to disperse pigments and ensure good leveling and spreading properties, which improves the quality of the coatings and the efficiency of their application.

4. ACMO shows excellent compatibility with oligomers, functional propionates and tree cells. In the preparation of composite materials, this good compatibility enables ACMO to be closely combined with other components to synergize their respective advantages and significantly improve the comprehensive performance of the materials. For example, in high-performance fiber-reinforced composites, the addition of ACMO can optimize the interfacial bonding between resin matrix and fibers, and enhance the mechanical properties and durability of the materials.

5. In the process of polymerization reaction, compared with most of the propionic acid monomers, the curing speed of ACMO has obvious advantages. From the point of view of chemical reaction kinetics, the molecular structure and reactive groups of ACMO enable it to react more efficiently with other monomers during the polymerization process to form a stable polymer network. This property is of great value in rapid prototyping processes. For example, in the field of 3D printing, resin materials using ACMO as one of the monomers can achieve rapid layer-by-layer curing, improving printing efficiency and model accuracy.

6. ACMO-modified UV and EB curing resins exhibit excellent resistance to moisture absorption, acids and alkalis, and solvents. In the coating of chemical storage containers, these resins are effective in resisting acid and alkali solutions and organic solvents, preventing rust and corrosion, extending the life of the container, and reducing maintenance costs and safety risks for organizations.

The nitrogen radical in the ACMO molecule contains a unique chemical activity that effectively inhibits oxygen-induced polymerization reactions. This property is critical in scenarios where the precision of the polymerization reaction is critical, such as in the preparation of optical materials, where the presence of ACMO ensures that the polymerization reaction proceeds as expected, avoiding defects due to oxygen interference, thus ensuring high transparency and stability of the optical properties of the optical material.

ACMO Monomer / 4-Acryloylmorpholine Features

1.water soluble monomer

2. quick curing

3. low viscosity

4. low volatility

5. less irritation to the skin.

ACMO Monomer / 4-Acryloylmorpholine Packaging and Shipping

Packing: 25L or 200L/drum.

Delivery:within 5-7 working days.

ACMO Monomer / 4-Acryloylmorpholine storage

Stored in a cool dry place out of direct sunlight.

Contact Us Now!

If you need Price and Sample Testing, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Elroy Joe –

good product, we order more samples for more tests hope to work with this supplier and get a good price for wholesale