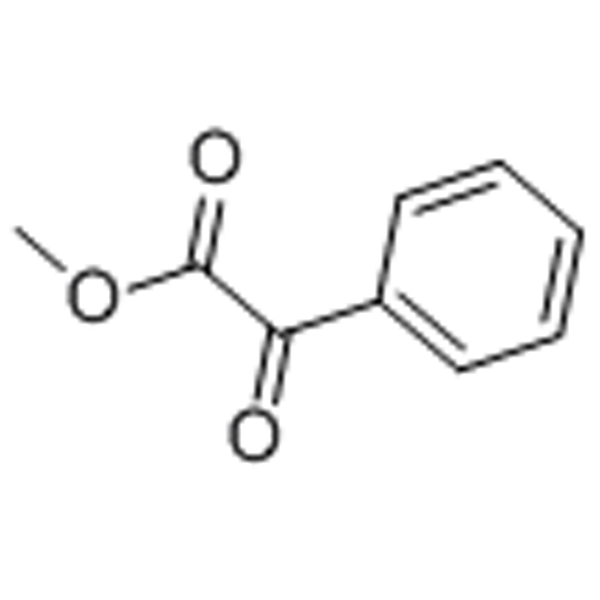

Photoinitiator MBF Application scenarios

1. Coatings

Industrial coatings, wood coatings, plastic coatings, metal coatings

Delivers excellent surface cure, low odor, low yellowing, ensuring coating aesthetics

2. Inks

Flexographic inks, screen printing inks, offset inks, inkjet inks

Rapid curing, low migration, suitable for applications requiring low odor and safety, such as food packaging

3. Adhesives

UV-curable adhesives and sealants

Liquid, easy to mix, fast curing speed

4. Other Applications

Overprint varnishes, nail gels

Low yellowing, high transparency, safer for human use

✨ Core Advantages & Application Recommendations

MBF offers two key advantages in applications:

Exceptional anti-yellowing capability:

Compared to common initiators like 184 and 1173, MBF significantly reduces yellowing in cured materials, making it ideal for appearance-critical varnishes and white/light-colored systems.

Suitable for Visible Light Curing:

While traditional MBF absorbs at shorter wavelengths (~325nm), its derivatives now match 405nm visible light LED sources. This enables safer, energy-efficient deep curing applications—such as achieving centimeter-level penetration in biomaterial 3D printing.

Reviews

There are no reviews yet.