Photoinitiator 6993 Application scenarios

1. Coatings and Coatings

Varnish coatings for metal, plastic, and paper surfaces, particularly suitable for thick coatings requiring deep curing with fast curing speed.

2. Inks and Adhesives

As a cationic initiator, suitable for ink and adhesive systems containing epoxy groups.

3. Professional and Research Applications

· Epoxy Resin Curing: Delivers superior curing properties.

· Polymer Synthesis: Used for oxidative polymerization of aromatic sulfides to synthesize polymers like polyphenylene sulfide.

· Photochemical Research: Serves as a cationic photoinitiator for studying photoinitiated polymerization reactions in the solid state.

Technical Characteristics and Usage Notes

Product Form and Properties:

Industrially supplied as a solution, e.g., a 50% acrylate solution, appearing as a pale yellow transparent liquid. Light-sensitive; store at room temperature in a dry, dark environment.

Mechanism of Action:

Unlike common cleaving-type free radical photoinitiators, it belongs to the cationic category. Under UV irradiation, it generates cationic active species, thereby initiating polymerization reactions in monomers such as epoxy resins. This reaction is typically less susceptible to inhibition by oxygen.

Safety Precautions:

This product is classified as a chemical raw material and must not be used in pharmaceuticals, food, cosmetics, or similar fields. Strict adherence to chemical safety regulations is required during handling.

Description

Photoinitiator 6993

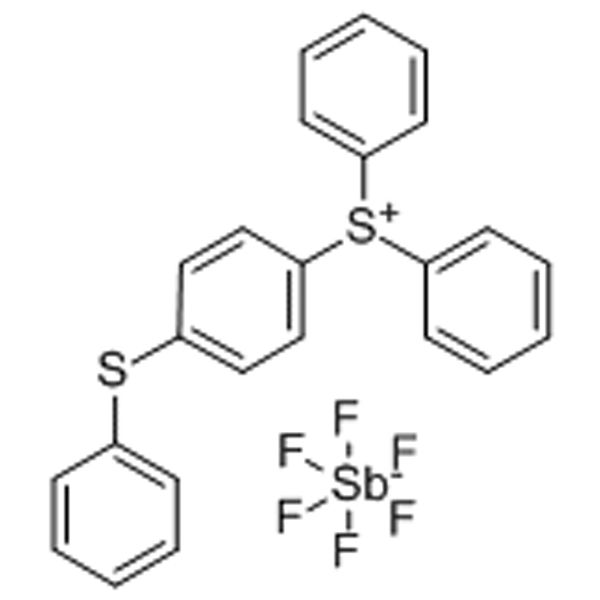

Synonym:UV Cationic Photoinitiator 6993;UVI-6993;UVI-6976 powder; Mixed type triarylsulfonium hexafluoroantimonate salts

CAS NO:71449-78-0

Standard:

| Appearance |

Off-white powder |

| Solid Content |

99% min |

| Dry Weight |

1% max |

UV Absorption Spectrum :

Applications:

1. Photoinitiator 6993: This photoinitiator excels at curing alicyclic epoxy resins such as Sinepoxy CER-421 and Sinepoxy CER-4299. It is perfectly matched to these alicyclic epoxy resins and enables efficient curing processes. In addition, it also has excellent curing effects on vinyl ethers and other cationic curing materials. From a historical perspective, the emergence and application of photoinitiators was a major innovation in material curing technology. In the past, the curing process of many materials was cumbersome and time-consuming, but the advent of photoinitiators greatly shortened this process, improved production efficiency, and promoted the rapid development of related industries.

2. A deeper analysis shows that in the application scenario of transparent coatings, the content of photoinitiator 6993 in the starting formulation is extremely critical. Its content is specified in the range of 1.5-3.0% (by weight). This figure was not set arbitrarily, but was determined through extensive experimentation and practical application. For example, in the early stages of product development, the content of photoinitiator 6993 was increased to 5%, but this was found to have caused an imbalance in some of the coating’s properties, such as an increase in hardness and a significant decrease in toughness, making the coating more prone to cracking when impacted by external forces. Conversely, if the content is too low, for example below 1%, the curing effect is not good, and the desired coating strength and stability requirements cannot be met. Therefore, the content range of 1.5-3.0% is the optimal range obtained after comprehensive consideration of the various performance indicators of the coating, which can ensure that the transparent coating has a good curing effect while maintaining balanced physical properties.

3. Let’s explore a new hypothetical scenario. Suppose that in the future, a special project requires the use of materials with a transparent coating and photoinitiator 6993 curing in an extremely harsh environment, such as deep-sea high pressure, strong corrosion, or high radiation and temperature changes in space. Then, would the existing 1.5 – 3.0% photoinitiator 6993 content range still meet the requirements? This requires further research and adjustment. Perhaps in the deep-sea environment, due to the high pressure and high corrosiveness of the seawater, the content of photoinitiator 6993 needs to be appropriately increased to enhance the curing strength and corrosion resistance of the coating, but at the same time, other performance issues that may be caused by too high a content, such as the previously mentioned decrease in toughness, need to be considered. In the space environment, in the face of high radiation and drastic temperature changes, it may be necessary to develop a new formulation system that can ensure the effective curing of photoinitiator 6993 while adding some special radiation-resistant and temperature-regulating materials that work synergistically with the existing ingredients to meet the requirements for use in the space environment.

Packaging and Shipping:

Packing:25kgs to 200kgs/drum.

Delivery:with in 5-7 working days.

Storage:

Stored in a cool dry place out of direct sunlight.

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Reviews

There are no reviews yet.