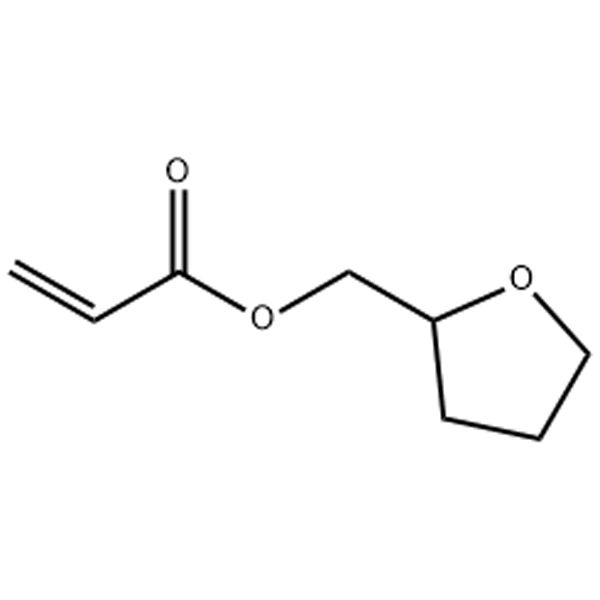

THFA Monomer Application scenarios

1. Coatings

Plastic coatings, metal coatings, paper coatings

Fast curing, strong adhesion (especially to PC materials), excellent weather and chemical resistance

2. Adhesives and Sealants

Structural/semi-structural adhesives, general-purpose bonding

Delivers high bond strength and flexibility, minimizes curing shrinkage

3. Inks

Flexographic, offset, screen printing, inkjet inks

Low viscosity, excellent dilutability, rapid curing speed

4. Polymer Production

Synthesis of specialty polymers (e.g., polyTHFA)

Enhances polymer toughness, thermal stability, and shape memory functionality

5. Emerging Applications

3D printing photopolymer resins, cosmetic film-forming agents

Achieves high precision and durability in 3D printing; improves skin feel in cosmetics

🛡️ Usage and Safety Precautions

When applying THFA, pay close attention to the following characteristics and safety considerations:

Core Properties:

Its low viscosity and high solubility enable it to function as an active diluent, effectively reducing system viscosity while participating in the curing reaction. The cyclic ether group in its molecular structure also provides excellent adhesion.

Safety Precautions:

THFA exhibits moderate skin irritation and sensitization potential. Always wear appropriate protective gear (e.g., gloves, safety goggles) during handling and ensure adequate ventilation in the work area.

Daniel Brown –

Lightning-fast delivery, superb quality, exceeded expectations. A truly satisfying shopping experience. Highly recommended!