Photoinitiator OXE-02 Application scenarios

1. Color Filters/Photoresists

Manufacturing of color photoresists and black matrices (BM) in liquid crystal displays (LCDs).

High sensitivity, suitable for pigment systems, enabling deep and rapid curing in colored systems. A mainstream high-end product in the market.

2. UV-Curable Materials

Formulations for coatings, inks, and adhesives.

Absorption range spans UVA to partial visible light, suitable for industrial applications requiring rapid curing.

3. Advanced Manufacturing & Microfabrication

Two-photon polymerization for fabricating 3D micro/nano structures (e.g., waveguides, photonic crystals).

Applicable to nonlinear optical processes, enabling complex 3D machining with submicron precision.

4. Biomaterials and Specialty Materials

Synthesis of polydimethylsiloxane-based biomaterials; applied research in food packaging, biomedicine, and related fields. Research focuses on leveraging their photochemical properties or developing derivatives with low migration and enhanced biocompatibility.

🔬 Technical Features and Advantages

High Photosensitivity and Deep Curing:

For pigmented systems (e.g., colored photoresists), light penetration is challenging. OXE-02’s high photosensitivity ensures thorough curing even at the bottom of coatings under low exposure or weak illumination conditions.

Excellent Thermal Stability:

Maintains strong chemical stability throughout production and storage.

Optimized for Specific Light Sources:

Its absorption spectrum aligns well with the UV wavelength bands emitted by certain exposure unit models, achieving optimal energy utilization efficiency and curing results.

Description

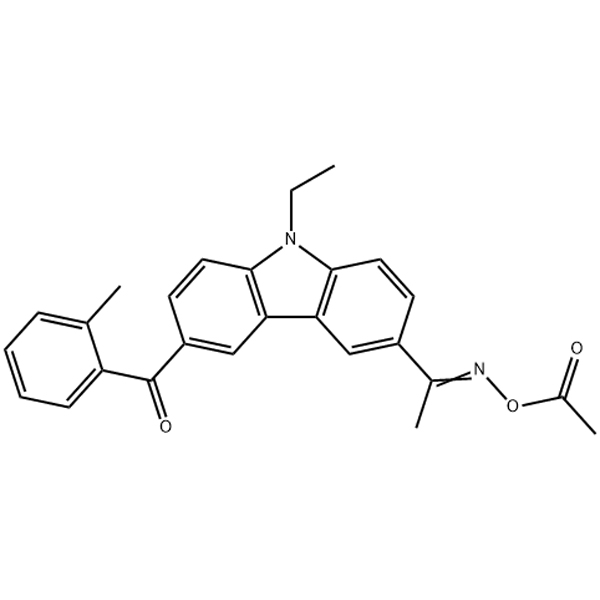

Photoinitiator OXE-02

Synonym: 1-(O-Acetyloxime)-1-[9-ethyl-6-(2-methylbenzoyl)-9H-carbazol-3-yl]ethanone; CHLUMINIT® OXE-02; Irgacure OXE-02

CAS No: 478556-66-0

Molecular Formula:C26H24N2O3

LED 375nm

General Information:

OXE-02 is an oxime ester photoinitiator with high photosensitivity and a broad absorption peak. OXE-02 can be used in conjunction with LEDs. OXE-02 can be used in both colorless and colored systems and is low in toxicity, odor, and environmentally friendly.

Specification:

| Appearance |

White to light yellow powder |

| Purity |

≥99% |

| Absorption peak |

295/368/380/400 |

| Volatile content |

≤0.5% |

| Melting point |

122-129°C |

CHLUMINIT® OXE-02 Usage:

From architectural decoration to electronic equipment manufacturing, from everyday printed matter to the production of high-end precision instruments, materials such as UV coatings, UV inks and UV adhesives all play an indispensable role. The application of the photoinitiator OXE-02 in these materials is extensive and significant. Take UV coatings, for example. In the coating of building facades, these coatings not only dry quickly, but also have excellent weather resistance. The photoinitiator OXE-02 plays a key role in initiating the polymerization reaction, which causes the coating to cure quickly and form a strong and beautiful coating. Similarly, UV inks used in the manufacture of electronic devices require high-precision printing results. Photoinitiator OXE-02 ensures that the ink cures precisely under UV light, ensuring the clarity and durability of the printed pattern.

It is also worth mentioning that it also performs excellently in the field of UV adhesives. For example, in the assembly of automotive parts, a fast-curing and high-strength adhesive is required, and UV adhesives are the first choice. The photoinitiator OXE-02 is the core factor that allows this adhesive to perform its powerful function. In addition, it also plays an irreplaceable role in preservatives and fluxes. In the corrosion protection of metal products that are exposed to harsh environments for long periods of time, corrosion inhibitors containing photoinitiator OXE-02 can form a dense protective film to effectively prevent the metal from being eroded by the external environment.

In actual use, there are strict requirements for the amount of photoinitiator OXE-02 used. According to a large amount of experimental data and industrial practice, the recommended dosage is 0.5–5% (w/w). This dosage range is not set arbitrarily, but is the result of repeated testing. When the dosage is lower than 0.5%, the polymerization reaction may not be initiated effectively, resulting in substandard product performance. For example, UV coatings may not dry completely, resulting in poor adhesion. When the dosage exceeds 5%, not only will the cost increase, but some negative effects may also occur. For example, excessive polymerization may make the product brittle, affecting its flexibility and durability.

this dosage range is also affected by other factors in different application scenarios, such as the intensity of UV light, irradiation time, ambient temperature, etc. Assuming that UV coating is applied in a high-temperature environment, due to the effect of temperature on the reaction rate, the dosage of photoinitiator OXE-02 may need to be slightly adjusted by reducing the dosage appropriately to avoid quality problems caused by excessive reaction. On the contrary, in a low-temperature environment or when the UV light intensity is weak, the dosage may need to be slightly increased to ensure the reaction proceeds normally. These are all complex factors that need to be considered in the actual production process, which further highlights the importance of accurately controlling the dosage of photoinitiator OXE-02.

Package:

1kg/Bag

Storage:

Stored in a cool dry place out of direct sunlight.

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Reviews

There are no reviews yet.