Description

Photoinitiator 369 CAS 119313-12-1

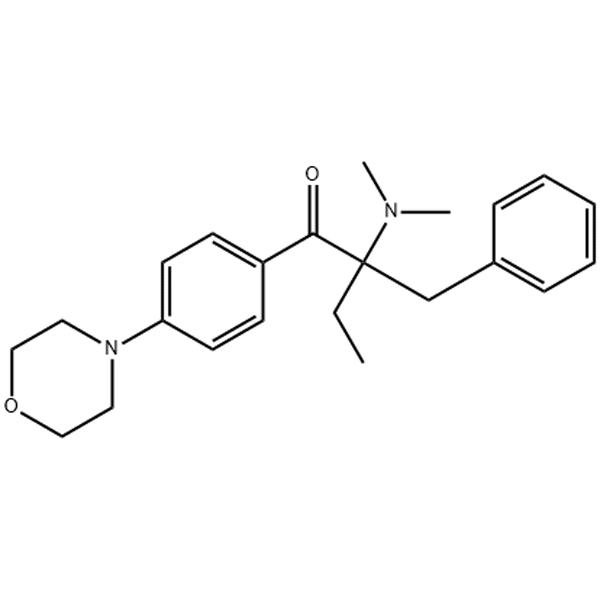

Chemial Name: 2-Benzyl-2-(dimethylamino)-4-morpholinobutyrophenone

CAS No: 119313-12-1

Other Name: irgacure 369; Genocure BDMM; Omnirad 369; Speedcure BDMB

Molecular Formula: C23H30N2O2

General Information:

369 is an efficient UV curing agent for initiating UV polymerization of unsaturated prepolymerized systems. After the photoinitiator is irradiated by ultraviolet light, it absorbs the energy of the light and splits into two active free radicals, which triggers the chain polymerization of the photosensitive resin and the active diluent, which is characterized by fast speed, environmental protection and energy saving.

Specification:

| Appearance | Slightly yellow powder | |

| Purity | ≥99% | |

| Volatiles | ≤0.3% | |

| Melting point | 110 – 119℃ | |

|

Transmittance |

450nm | ≥90% |

| 500nm | ≥98% | |

| Clarity of solution | Clear | |

Usage:

The unique charm of photoinitiator 369 lies in its superlative ability to “capture” long-wave ultraviolet light (350 – 380 nm). This ability is like a magical key that can unlock the mystery of curing deeper or pigmented coatings. In these special UV curing applications, it is like a professional magician, casting the spell of deep curing to perfectly treat every corner.

In practical UV curing applications, photoinitiator 369 shows its amazing strength.

When we look at the field of thick film and deep coatings, we can see that photoinitiator 369 is irreplaceable. Just as the foundation of a building needs to be solid, the curing quality of thick film coatings is crucial. Take thick film coatings on wood, metal and plastic as an example. In furniture manufacturing, machine protection and plastic product processing, the quality of the coating is directly related to the life and performance of the product. With its long absorption wavelength, photoinitiator 369 can penetrate deep into the coating like an intrepid explorer, ensuring consistent curing from the inside out. It’s like building a sturdy castle: 369 ensures that every “brick” (coating molecule) is tightly bonded, so that the castle (product) can withstand all kinds of erosion and stand for a long time.

369 is also the master in the world of high opacity and dark inks. We all know that the curing quality of the ink has a decisive influence on the printing result. In some printed matters that require a dark or opaque effect, such as art posters and high-end packaging, traditional photoinitiators may not be able to meet the requirements. But 369’s excellent initiation efficiency under long-wave UV light is like a ray of light piercing the fog, enabling every last part of colored and opaque coatings (such as dark inks and paints) to be fully cured. It ensures that even deep-layered ink materials are perfectly cured, resulting in vibrant, long-lasting prints.

For UV-curing adhesives, photoinitiator 369 is a premium choice. In modern technology products, the bonding of glass, plastic and optical components requires extremely high precision and quality. For example, in the manufacture of smartphones, the bonding of the screen to the body and the assembly of optical lenses all place stringent requirements on the transparency and stability of the glue. 369 has low yellowing after curing, which is like injecting a “preservative” into the glue, keeping it clear and transparent during long-term use, providing a reliable guarantee for these high-precision bonding applications.

Photoinitiator 369 also shines in the field of 3D printing photoresins. With the rapid development of 3D printing technology, there is an increasing demand for printing complex and thicker structures. In this innovative field, the good permeability of 369 is like a precise navigator, guiding the UV light through thicker 3D printed structures and ensuring that each layer is fully cured. It also has excellent compatibility with long-wave UV LED (e.g. 365 nm or 405 nm) light sources, which can trigger efficient curing at lower energy. This is like equipping a 3D printing device with a high-performance engine, resulting in clearer model details, whether it is an intricate jewelry model or a complex mechanical part model, achieving near-perfect results.

369 is also extremely versatile when it comes to UV-curing protective coatings. Electronic products and optical components are like delicate treasures that require special protection. These protective coatings must remain transparent and yellowing-resistant after curing in order not to affect the performance and appearance of the product. In the application of optical coatings and protective films, especially in scenarios where a thick, uniform curing is required, 369 acts like a caring guardian, providing these delicate devices and components with a strong, transparent “protective clothing” to protect them from the external environment.

It is worth mentioning that photoinitiator 369 is usually used in combination with other initiators (such as 184, TPO, 1173, etc.), and this combination can be called the “golden partner” in the field of light curing. They work together like a well-trained team, working towards a common goal. This combination achieves better curing results and optimizes the properties of the material. From a chemical perspective, the different initiators have different chemical activities and mechanisms of action. Their synergistic effect can increase the curing speed, improve permeability, and ensure the long-term stability and reliability of coatings and adhesives in demanding applications. It’s like a wonderful symphony performance, where each instrument (initiator) plays a unique role, and together they create a magnificent performance of light curing.

Recommended dosage:

- Offset inks : 2 – 4 % 369

- Screen inks: 2 – 4 % 369 + 1 – 3 % 184

- Pigmented coatings: 1 – 4 % 369

- Photopolymers for imaging applications: 0.5 – 5 % 369

Package:

20kg/carton.

Storage:

Stored in a cool dry place out of direct sunlight.

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Reviews

There are no reviews yet.