Photoinitiator 160 Application scenarios

1. Industrial Coatings

Primarily used for transparent or colored coatings on substrates such as wood, plastic, and metal. Its low odor and low migration properties also make it an ideal choice for food packaging-related coatings.

2. Graphic Arts and Printing

Widely used in inkjet inks and printing inks, ensuring rapid drying and rich color reproduction on media like paper and plastic.

3. Emerging & Electronic Fields

A key component in 3D printing photopolymers (e.g., SLA), and used in protective coatings for electronic materials like optical fibers.

4. Adhesives

Suitable for fast-curing UV adhesives, playing a role in processes such as electronic assembly and glass lamination.

🔬 Key Properties and Advantages

Exceptional Reactivity and Compatibility:

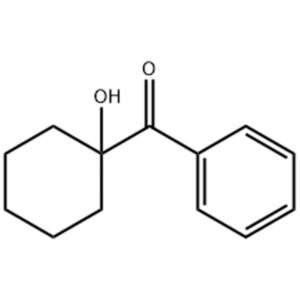

As a difunctional α-hydroxyketone, it generates highly reactive free radicals that effectively penetrate pigment systems for deep curing, delivering outstanding performance in colored coatings and inks.

Exceptional Safety and Environmental Performance:

The product’s greatest advantage lies in its extremely low volatile organic compounds (VOC) content. After curing, minimal small-molecule residues remain in the finished product (low migration, low extraction), meeting stringent regulatory requirements for food contact materials, children’s toys, and similar applications.

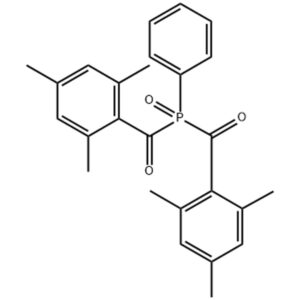

Extended Absorption Wavelength:

Its molecular structure shifts the absorption spectrum toward longer wavelengths, enabling better alignment with the emission spectrum of conventional medium-pressure mercury lamps. This enhances energy utilization efficiency and curing efficiency.

Description

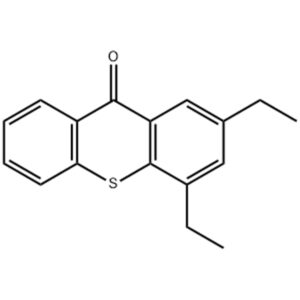

Photoinitiator 160 / ESACURE KIP 160 CAS 71868-15-0

Synonym: ESACURE KIP 160

Standard:

| Items |

Specifications |

| Appearance |

White powder |

| Assay (HPLC) |

≥99.0% |

| Melting point |

98~102°C |

| Volatiles |

≤0.2% |

| Acid value(Mg KOH/g) |

≤0.2 |

| Ash |

≤0.1% |

Function & Applications:

1. Photocure 160 is an excellent choice for painting wood, which is common in the construction industry, whether it is used for antique and elegant wood-carved doors and windows or modern minimalist-style wooden floors. During the painting process, it ensures that the paint adheres better to the wood surface, improving the wood’s wear and corrosion resistance, as if it were wearing a tough layer of “armor”. Thanks to its unique chemical structure and reaction mechanism, when exposed to light of a specific wavelength, it can initiate a series of photochemical reactions, causing the paint to dry and cure quickly.

In the field of plastic products, we all know that plastics are widely used in electronic equipment housings, toys, household goods and other products. The use of photoinitiator 160 can greatly improve the quality of plastic surface coatings. Take children’s toys as an example. Toys are often subject to bumps, friction and the erosion of the external environment. If the coating quality is not good, it is easy to fade or be damaged. The use of coatings containing photoinitiator 160 can make the colors on the surface of toys more durable and bright, protecting children’s happy time.

Photocure 160 is also used in a wide range of paper applications, from book printing to food packaging labels. Its safety has been rigorously tested in food packaging. According to relevant research data (the latest research report on the safety of food packaging materials can be cited here), under normal conditions of use, photocure 160 does not migrate harmful substances into food, providing a reliable safeguard for the food packaging industry. Compared with the traditional processing methods of packaging materials, it can ensure food safety while improving the aesthetics and durability of the packaging.

Photoinitiator 160 is also indispensable for the surface treatment of metal materials. In the automotive industry, the metal parts of the car body need to be treated for corrosion protection and aesthetics. The coating system involving photoinitiator 160 can dry quickly and form a dense protective film on the metal surface, effectively preventing the metal from rusting while giving the car a beautiful appearance. Moreover, it can meet the high requirements for coating accuracy and stability in the processing of some high-precision metal parts.

The field of optical fibers places extremely high demands on the properties of the materials, and photoinitiator 160 is also up to the task. The transmission performance of optical fibers depends to a large extent on the quality of their surface coating. A high-quality coating can reduce the loss of optical signals and ensure the stability of signal transmission. The use of photoinitiator 160 in the optical fiber coating process provides strong support for the construction of high-speed and stable communication networks.

Powder coatings are also becoming more popular in the furniture and machinery industries. The use of photoinitiator 160 in powder coatings not only improves the curing efficiency of the coating, but also the physical properties of the coating. For example, the use of photoinitiator 160 in the powder coatings of some outdoor furniture can ensure that the furniture maintains a good appearance and performance even after being exposed to the sun and rain.

Packaging and Shipping:

Packing:20kg/carton box.

Delivery:with in 5-7 working days.

Storage:

Stored in a cool dry place out of direct sunlight.

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Reviews

There are no reviews yet.