Antioxidant TTDP Application scenarios

1. 폴리염화비닐(PVC)

Rigid and flexible PVC products

Provides processing thermal stability and prevents high-temperature discoloration and degradation.

This is one of its most important and mature applications. It can also synergize with metal salt stabilizers in PVC to enhance their effects.

2. Other Plastics and Elastomers

ABS, SBR, CR, etc.

As an auxiliary antioxidant, it improves the thermal and oxygen stability of the material.

Often used as an environmentally friendly, phenol-free stabilizer option for these materials.

3. Polyolefins

Linear Low-Density Polyethylene (LLDPE)

Used as an antioxidant.

Note that the FDA has approved its use in food contact LLDPE products under certain conditions.

4. Polyurethane (PU)

Polyurethane materials

As an antioxidant, it provides thermal stability and helps prevent yellowing.

The industry is developing new alternatives with better performance (such as better hydrolysis resistance).

📝 Usage Instructions and Precautions

In practical applications, the following key points need to be understood:

• Regulations and Restrictions: According to the U.S. Food and Drug Administration (FDA), TTDP is approved for use in certain types of food contact materials (such as PVC and LLDPE), but with clear dosage restrictions. It is particularly important to note that this approval explicitly excludes its use in products that come into contact with infant formula and breast milk.

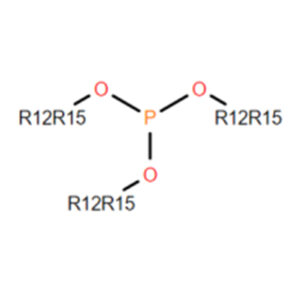

• Synergistic Use: As a phosphite-based auxiliary antioxidant, TTDP is often used synergistically with hindered phenolic primary antioxidants to achieve a more comprehensive anti-aging effect.

• Cutting-Edge Research Applications: Some academic research explores its derivatives as electrolyte additives in high-voltage lithium-ion batteries to improve battery performance, but this is cutting-edge research and has not yet been widely applied industrially.