Antioxidant 1222 Application scenarios

1. Polymer and Plastics Industry (Main Application Areas)

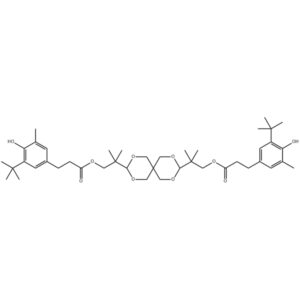

Antioxidant 1222 is particularly suitable for engineering plastics and high-performance fibers, materials that typically require high-temperature processing or use in harsh environments.

Polyamides

Nylon 6 (PA6) and Nylon 66 (PA66): This is the most classic and important application area for antioxidant 1222. It effectively prevents thermal oxidative degradation of nylon during high-temperature processing such as melt spinning and injection molding, maintaining stable molecular weight and melt viscosity, thereby ensuring fiber strength and the mechanical properties of plastic products. It also provides long-term heat aging resistance.

Polyesters

Polyethylene terephthalate (PET): Adding antioxidant 1222 during PET resin synthesis (high-temperature polycondensation) and subsequent spinning and blow molding processes prevents yellowing and viscosity reduction, which is crucial for the production of high-viscosity flakes, industrial filaments, and films.

Polybutylene terephthalate (PBT): Also used to ensure the stability of PBT during processing and use.

Polyacetals

Polyoxymethylene (POM): POM is sensitive to oxidation. Antioxidant 1222 can effectively inhibit its thermal oxidative decomposition, extending product life.

Other Polymers

Polyurethane (PU): Especially used in thermoplastic polyurethane (TPU) and certain elastomers, providing thermal stability protection.

폴리카보네이트(PC): As part of the stabilizing system in certain blends or specific grades.

2. Key Characteristics and Advantages (Explaining the Reasons for Its Wide Application)

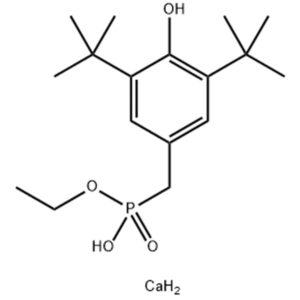

High Efficiency and Synergistic Effect: One molecule possesses two antioxidant mechanisms, resulting in high efficiency and relatively low addition levels (typically 0.1%-0.5%).

Low Volatility and High Extraction Resistance: Large molecular weight, not easily volatilized during high-temperature processing; good compatibility with polar engineering plastics (such as PA, PET), not prone to migration and exudation, suitable for making products requiring long-term stability or contact with liquids.

Good Color Protection: Effectively inhibits yellowing of polymers during processing and use.

Compliant with food contact regulations: In many countries and regions, it is approved for use in food contact polymer products (subject to specific regulations).

3. Specific Application Examples

Fibers: Automotive tire cord (e.g., nylon 66 cord), industrial yarns, high-end textiles, seat belts, etc.

Engineering Plastic Components: Automotive engine peripheral components (intake manifolds, cooling system parts), electronic connectors, gears, bearings, etc.

포장 재료: Heat-resistant PET bottles (e.g., hot-fill beverage bottles), food packaging films.

Industrial Materials: Pipes, coatings, adhesives, etc.

In summary, the core application scenarios for antioxidant 1222 are in polar engineering plastics and synthetic fibers that require high-temperature processing and/or excellent long-term thermal stability. It is a very important and classic component in the stabilization formulations of nylon and polyester materials.

아폴로 로즈 -

놀라운 서비스와 제품! 배송이 매우 빨랐고 상품도 잘 포장되어 있었어요. 더 이상 바랄 게 없었어요!