Mengapa benzofenon tidak larut dalam air? Apakah benzofenon bersifat polar atau nonpolar?

Benzofenon adalah fotoinisiator yang sangat penting dalam bidang pembuatan tinta. Namun demikian, pertanyaan mengenai apakah benzofenon bersifat polar atau non polar, dan kelarutannya dalam pelarut yang berbeda-beda, telah merisaukan banyak praktisi. Pada artikel ini, kami akan menganalisis sifat polar benzofenon, untuk menjawab pertanyaan tentang ketidaklarutannya dalam air tetapi larut dalam beberapa pelarut alkohol, untuk penggunaan fotoinisiator benzofenon pabrik pembuatan tinta benzofenon untuk memberikan pengetahuan dan wawasan yang berharga.

Pertama, dasar penilaian polaritas benzofenon

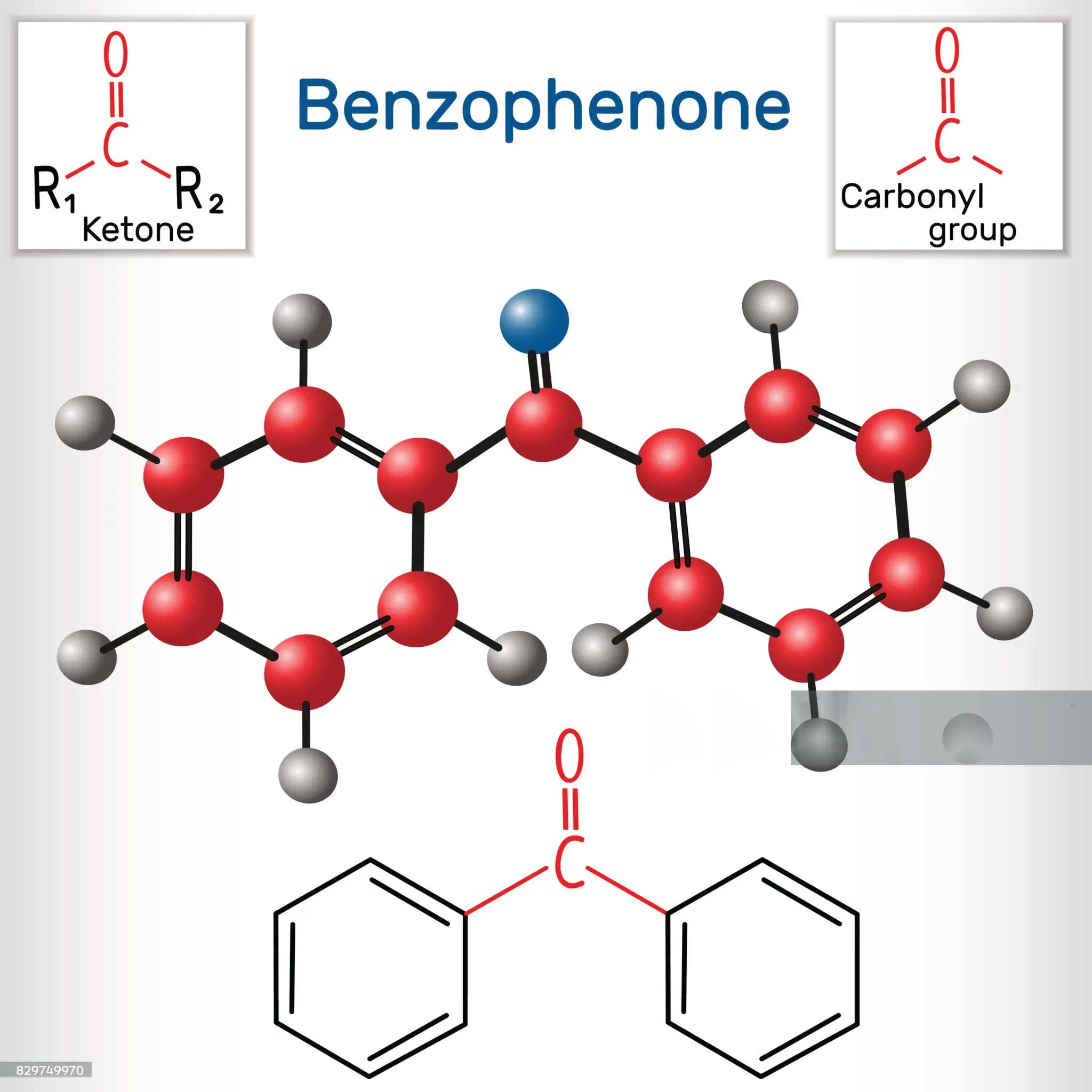

Struktur molekul benzofenon memiliki pengaruh utama pada polaritasnya. Secara umum, molekul polar terdiri dari atom-atom dengan keelektronegatifan yang berbeda, dan struktur molekulnya asimetris, serta terdapat momen dipol. Struktur benzofenon mengandung gugus karbonil (C=O), yang memiliki polaritas tertentu. Namun, pada saat yang sama, struktur cincin benzena memiliki karakter non-polar yang besar. Dalam hal keseluruhan molekul, volume cincin benzena dan distribusi awan elektron yang lebih luas membuat benzofenon menunjukkan polaritas yang lebih lemah. Sebagai contoh, dalam beberapa percobaan perbandingan polaritas molekul yang serupa, kinerja polaritas benzofenon secara signifikan lebih rendah dibandingkan dengan beberapa molekul yang sangat polar seperti metanol. Ini juga merupakan alasan penting untuk ketidaklarutannya dalam air, karena air adalah pelarut polar yang kuat, sesuai dengan prinsip 'kelarutan yang sama', polaritas benzofenon yang lemah sulit larut dalam air.

Analisis kelarutan benzofenon dalam pelarut alkohol

Ketika mengeksplorasi kelarutan benzofenon dalam pelarut alkohol, situasinya menjadi lebih kompleks. Di satu sisi, benzofenon sendiri tidak larut dalam air karena polaritasnya yang lemah dan ketidakmampuannya untuk membentuk ikatan hidrogen dengan air (karena tidak adanya atom hidrogen dalam molekulnya yang terikat pada O, N, atau F). Namun demikian, dalam pelarut alkohol, telah didokumentasikan dapat membentuk ikatan hidrogen. Ini karena molekul alkohol (misalnya, etanol, CH₃CH₂OH) memiliki bagian gugus hidrokarbon non-polar dan bagian hidroksil (-OH) polar. Atom oksigen karbonil benzofenon dapat membentuk ikatan hidrogen dengan atom hidrogen hidroksil molekul alkohol, sehingga memungkinkan kelarutan sampai batas tertentu. Misalnya, dalam percobaan pencampuran tinta, ketika menggunakan etanol sebagai pelarut, benzofenon dapat secara bertahap dilarutkan dan didispersikan secara seragam dalam sistem di bawah aksi pengadukan, dll., Yang merupakan perwujudan ikatan hidrogen. Namun, kelarutan ini tidak terbatas, hal ini dipengaruhi oleh berbagai faktor seperti struktur molekul alkohol, konsentrasi dan suhu.

Ketiga, signifikansi praktis dari pembuatan tinta

Untuk penggunaan pabrik tinta pembuatan benzofenon, memahami polaritas dan kelarutan benzofenon memiliki nilai praktis yang penting. Dalam desain formulasi tinta, untuk sepenuhnya mempertimbangkan kompatibilitas benzofenon dengan pelarut, resin, dan komponen lainnya. Jika pelarut yang tidak sesuai dipilih, hal ini dapat menyebabkan benzofenon tidak terlarut atau terdispersi secara memadai, sehingga memengaruhi performa tinta, seperti kecepatan pengeringan dan daya rekat. Misalnya, jika sejumlah besar pelarut non-polar digunakan dalam formulasi dan pencocokan benzofenon dengan pelarut polar diabaikan, tinta dapat mengendap atau terdelaminasi selama penyimpanan. Oleh karena itu, penyesuaian sistem pelarut yang wajar, sesuai dengan karakteristik benzofenon untuk memilih proporsi pelarut polar dan non-polar yang sesuai, dapat mengoptimalkan kualitas tinta dan proses produksi.

Dalam proses produksi tinta, memahami sifat-sifat benzofenon ini, juga membantu mengontrol kondisi produksi. Misalnya, suhu berpengaruh pada kelarutan benzofenon dalam pelarut, dan peningkatan suhu yang sesuai dapat meningkatkan kelarutannya, tetapi juga perlu mempertimbangkan pengaruh suhu pada komponen lain dan stabilitas keseluruhan tinta. Pada saat yang sama, dalam pengadaan bahan baku, pengujian kemurnian dan kualitas benzofenon juga dapat digunakan untuk membantu penilaian dari aspek kelarutannya, untuk memastikan bahwa penggunaan benzofenon sesuai dengan persyaratan produksi.

Dari sudut pandang pribadi saya, benzofenon dalam kelarutan karakteristik ini memang menghadirkan banyak tantangan dan pemikiran pada pembuatan tinta. Di masa lalu, beberapa percobaan dan praktik produksi, saya temui karena pemahaman yang tidak akurat mengenai kelarutan masalah kualitas tinta benzofenon yang disebabkan oleh studi mendalam dan penyesuaian sistem pelarut yang harus diselesaikan. Hal ini juga mengingatkan kita, bahwa di bidang pembuatan tinta, karakteristik tiap bahan baku perlu ditelusuri secara mendalam untuk menghasilkan produk berkualitas tinggi.

Dalam proses pembuatan tinta, Anda juga bisa mempertimbangkan untuk menambahkan sejumlah aditif untuk meningkatkan kelarutan dan penyebaran benzofenon. Sebagai contoh, beberapa surfaktan dapat mengurangi tegangan permukaan sistem dan meningkatkan pencampuran benzofenon dengan pelarut dan bahan lainnya. Pada saat yang sama, pemilihan peralatan produksi dan optimalisasi parameter proses perlu dikombinasikan dengan karakteristik benzofenon. Misalnya, penggunaan peralatan pencampuran yang efisien dan kecepatan pencampuran yang sesuai dapat mempercepat proses pelarutan benzofenon dan meningkatkan efisiensi produksi.

Jika Anda ingin mengetahui lebih lanjut mengenai karakteristik bahan baku dan pengoptimalan proses dalam pembuatan tinta, silakan berlangganan buletin industri kami untuk mendapatkan konten yang lebih profesional.

Kesimpulannya, polaritas dan kelarutan benzofenon merupakan faktor penting yang tidak dapat diabaikan dalam pembuatan tinta. Dengan memahami secara mendalam sifat-sifatnya dan menerapkannya pada produksi aktual, Anda dapat meningkatkan kualitas dan produktivitas produk tinta serta memenangkan keuntungan bagi perusahaan Anda dalam persaingan pasar. Pernahkah Anda mengalami masalah terkait kelarutan dalam proses penggunaan benzofenon untuk memproduksi tinta? Selamat berbagi di bagian komentar.

Hubungi Kami Sekarang!

Jika Anda membutuhkan Harga, silakan isi informasi kontak Anda di formulir di bawah ini, kami biasanya akan menghubungi Anda dalam waktu 24 jam. Anda juga bisa mengirim email kepada saya info@longchangchemical.com selama jam kerja (8:30 pagi hingga 6:00 sore UTC+8 Senin-Sabtu) atau gunakan obrolan langsung situs web untuk mendapatkan balasan secepatnya.