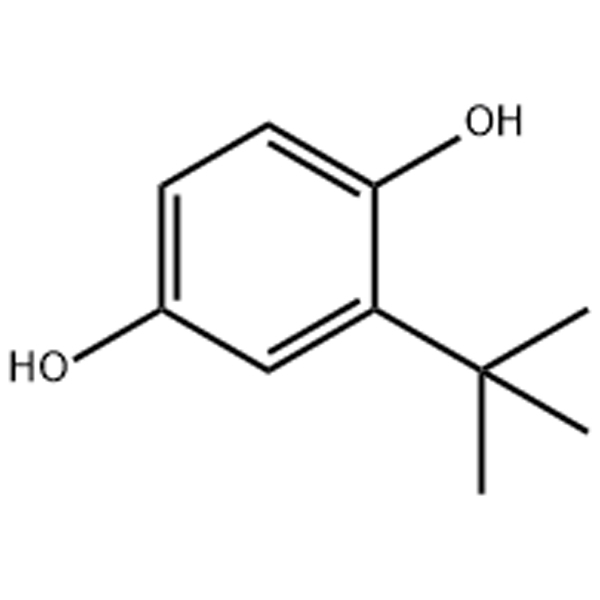

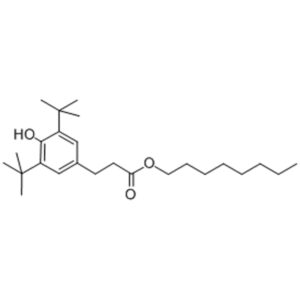

Antioxidant TBHQ Application scenarios

I. Food Industry (Most Important and Widest Application)

TBHQ is primarily used in food to prevent rancidity, discoloration, and nutritional value loss in oil-rich foods due to oxidation.

Oils and Fats

Edible Vegetable Oils: Such as soybean oil, rapeseed oil, palm oil, peanut oil, etc., added after refining or before storage and transportation to prevent oxidation during shelf life.

Animal Fats: Such as lard, tallow, etc.

Fried and Baked Foods:

Instant Noodles: Protecting the fried dough in the noodle cake is a very important application for TBHQ.

Snacks such as Potato Chips, Shrimp Crackers, and Nuts: Preventing oil-rich snacks from spoiling during storage.

Biscuits and Pastries: Protecting shortening, butter, and other ingredients.

Meat Products

Used in processed or pre-cooked meat products (such as frozen meat skewers and meatballs) to prevent fat oxidation and unpleasant flavors.

Other Foods

Used in dehydrated soup mixes, sauces, pet food (containing oily portions), and certain candies. Application Standards in Food: In China, the use of TBHQ must comply with the “National Food Safety Standard – Standard for the Use of Food Additives” (GB 2760-2014). The maximum allowable usage is typically 0.2 g/kg (based on its content in oils). It is often used in combination with other antioxidants (such as BHA and BHT) to produce a synergistic effect.

II. Bulk Commodities and Industrial Raw Materials

TBHQ is also used to protect the stability of non-directly ingested oils or oily materials during industrial storage and transportation.

Biodiesel: As a stabilizer for biodiesel, it prevents oxidation and deterioration during storage, maintaining fuel quality.

Industrial Oils: It protects the base oils in some industrial lubricants and metalworking fluids.

Feed Industry: Added to animal feeds with high oil content or feed oils to prevent feed rancidity and ensure feed quality and animal health.

III. Non-Food Industrial Applications

Utilizing its antioxidant properties, TBHQ is also applied in the following industries:

Polymer Materials

As an antioxidant for plastics such as polyethylene (PE) and polypropylene (PP), it prevents polymer degradation due to thermal oxidation during processing, maintaining material properties.

Used in rubber, adhesives, and sealants to improve their aging resistance.

Cosmetics and Personal Care Products

Added to oil-containing cosmetics (such as lipsticks, creams, and sunscreens) to prevent the oil components from oxidizing and becoming rancid, extending product shelf life and maintaining color and odor stability. In this field, it is usually used as a formulation stabilizer rather than a primary functional ingredient.

Summary and Characteristics

High Efficiency: Exhibits excellent antioxidant effects even at low concentrations (usually far below the national standard limit).

Heat Resistance: Remains stable at high temperatures (such as during frying), providing good “carryover” protection, a key advantage over some natural antioxidants (such as vitamin E).

Wide Range of Applications: Covers numerous scenarios requiring protection against oil oxidation, from food to industrial products.

Importance of compliance: Its application in food must strictly adhere to the regulations and limits of the country or region in which it is used. Although its safety has been extensively assessed and its use approved, excessive use may pose health risks.

Emily Clark -

Außergewöhnlicher Service, schnelle Antworten, reibungslose Logistik, glückliches Einkaufen!