Photoinitiator MBP Application scenarios

1. UV-Curable Coatings and Inks

· Inks: Offset printing inks, flexographic printing inks, screen printing inks, lithographic printing inks.

This represents MBP’s core application area. Enables rapid curing to enhance production efficiency.

· Coatings: Wood coatings, plastic coatings, industrial coatings, overprint varnishes (gloss varnishes).

Provides surface protection for substrates including paper, wood, metal, and plastic.

· Electronic Materials: Specialized coatings or encapsulation materials for electronics.

Requires specific curing performance and material stability.

2. Adhesives

UV-curable adhesives.

Suitable for applications requiring rapid bonding and fixation.

3. Other Functional Applications

· UV Absorbers: Used in products requiring UV aging resistance.

Leverage their UV-absorbing properties for stabilization and protection.

· Pharmaceutical intermediates: Chemical raw materials for synthesizing certain drugs.

Classified under fine chemical applications.

Technical Characteristics and Usage Points

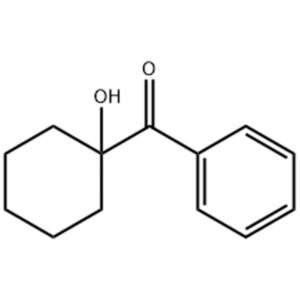

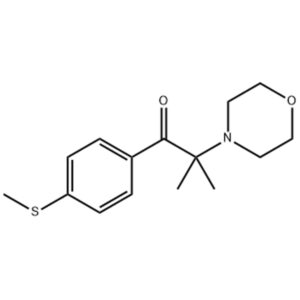

· Mechanism of Action:

MBP is a Type II photoinitiator incapable of directly generating free radicals. It absorbs UV light (maximum absorption wavelength ~259 nm) and extracts hydrogen atoms from co-added amine synergists (e.g., tertiary amines) to generate polymerization-initiating free radicals.

·Recommended Dosage:

The suggested addition rate in formulations is generally 0.5%–5% by total weight.

·Key Advantages:

Highly reactive, providing excellent surface curing performance with minimal yellowing after cure. Suitable for transparent or colored systems with stringent color requirements.

Reviews

There are no reviews yet.