What are bio-based plasticizers and what are the advantages of our CHLUMIFLEX® BBP?

Plasticizers make PVC materials soft and easy to process, and are widely used in plastic production. Phthalates plasticizers account for 85% of the total plasticizer market. Considering toxicity, the application of o-phthalic plasticizers is limited, and the bio-based plasticizer industry has begun to deploy the market.

As a chemical that softens materials such as plastics, plasticizers are widely found in toys, food packaging materials, nail polish, shampoos, medical appliances, and even food products, but some plasticizers may cause tissue damage. Cancer, disrupt human endocrine and so on. As a result, bio-based plasticizers that are non-toxic to the human body and non-polluting to the environment emerge as the times require, becoming an ideal choice to replace traditional plasticizers.

The source of bio-based plasticizers is stable, and the price advantage and stability are more prominent than traditional plasticizers,

In recent years, more and more manufacturers have begun to deploy bio-based plasticizers in the market. We have also made some phased progress and breakthroughs in the field of bio-based plasticizers, and have received wide recognition from PU and glove customers.

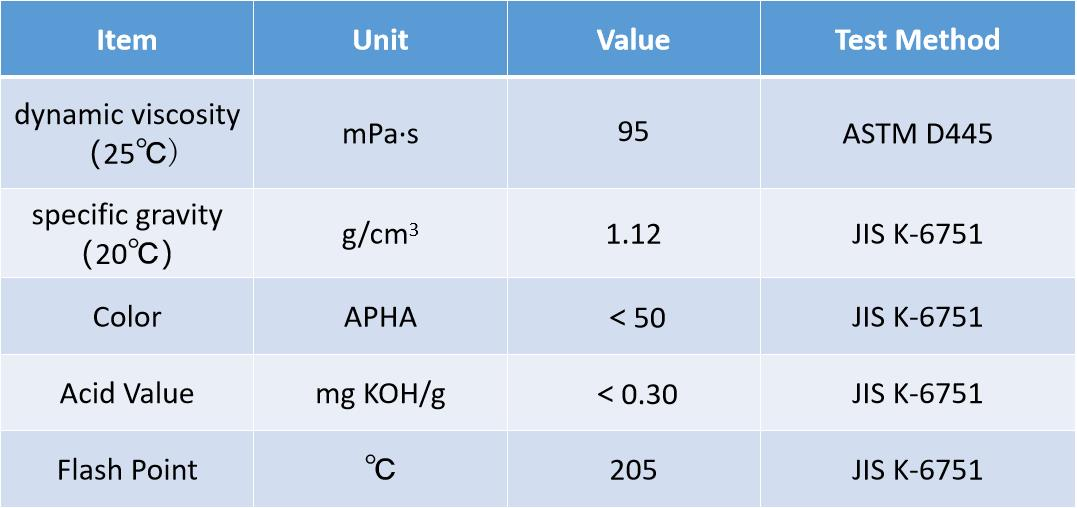

CHLUMIFLEX® BBP infos

Brief Introduction

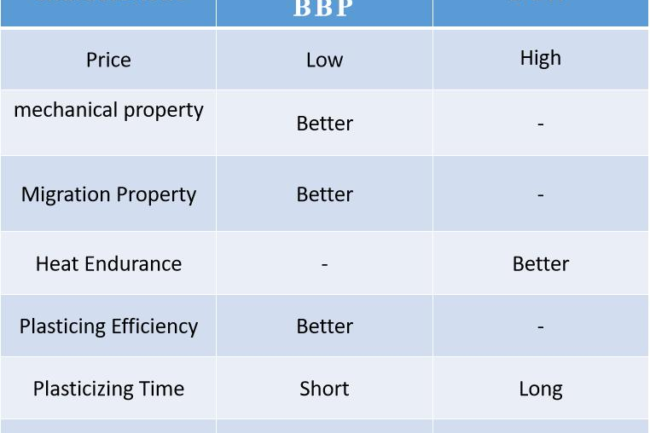

CHLUMIFLEX® BBP has the most approximate physical property to DOTP among the all existing PVC plasticizers.

CHLUMIFLEX® BBP can be applied to PVC flooring, cable and wires, films, etc.

CHLUMIFLEX® BBP has better performance in plasticizing efficiency, mechanical property, migration property and blending time. It’s the best substitute of DOTP.

Advantage

Comparison with DOTP and DINCH

CHLUMIFLEX® BBP’s plasticizing speed is about 2 times of DOTP or DINCH. Using CHLUMIFLEX® BBP can save energy and improve production efficiency.

Using CHLUMIFLEX® BBP to replace DOTP or DINCH by 100% can reach same plasticizing effect, ajustment in formular or production line is not needed.

Using CHLUMIFLEX® BBP can improve end product’s transmittancy and Haze.

CHLUMIFLEX® BBP has same Migratory resistance as DOTP .

CHLUMIFLEX® BBP has better mechanical property than DOTP does.

Product indicators

Horizontal comparison of various product application indicators DOTP and DINCH

- Superior environment-friendly plasticizer

– Regulation (EC) No 1907/2006

– Antimicrobial testing by SGS

- Sustainability of raw material

– Raw material comes from plant oil, non-toxic, bezene-free, biodegradable.

- outstanding physical property

-Better migration property than DOTP does.

-Better plasticizing power than DOTP does.

-Lower price (Now CHLUMIFLEX® BBP is CNY400~500/mt lower than DOTP, a factory can save 2.4million CNY per year with monthly consumption of 600mt)

conclusion

CHLUMIFLEX® BBP has better migration property than DOTP does.

It has great application space in the printed PVC and composite flooring.

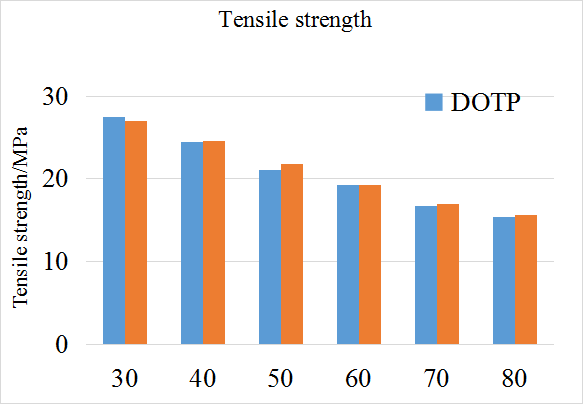

Test of tensile strength

conclusion

Tensile Strength is an important index of plastic mechanical properties

The sample is subjected to an external force (tensile load) until the maximum tensile force before fracture

CHLUMIFLEX® BBP’s tensile strength is nearly same as DOTP. Using CHLUMIFLEX® BBP to replace DOTP does not affect the end products’ tenacity. Same plasticizing efficiency (Evaluated by tensile strength)