Polythiol PM839 应用场景

1.环氧树脂固化剂/促进剂

作为一种液体固化剂,它具有颜色浅、毒性低的特点。

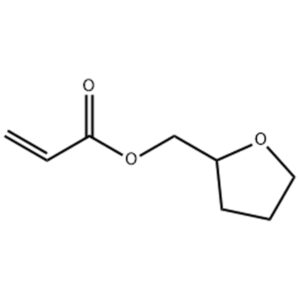

2.快速固化系统

在低温和薄膜涂层条件下,可实现极快的固化速度。

3.冬季或低温应用

特别适用于快速固定粘合剂和需要低温固化的情况。

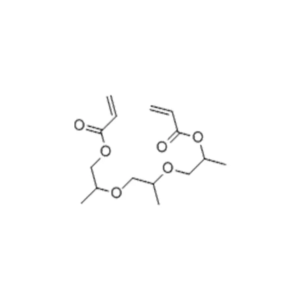

4.高性能涂料和粘合剂

用于快干涂料、粘合剂和浇注塑料,以提高最终产品的机械性能和耐用性。

主要产品特性和使用建议

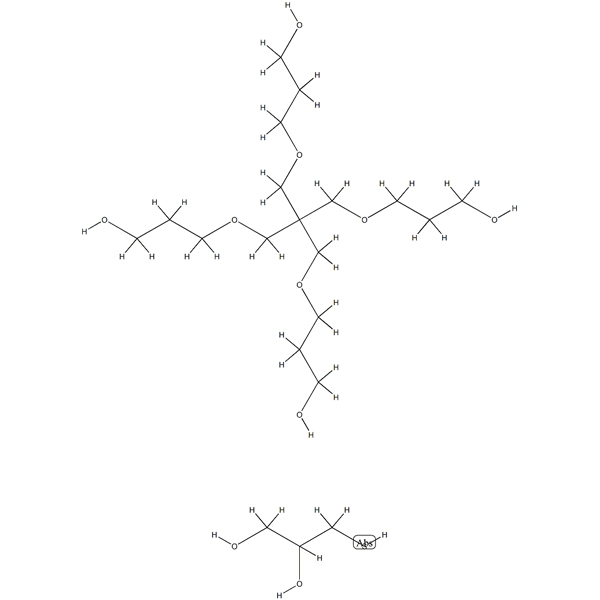

物理特性 根据供应商提供的数据,该产品为无色或淡黄色液体,25°C 时密度约为 1.13-1.17 g/cm³,粘度较高。

使用说明: 它通常与胺类固化剂协同使用,以进一步加快固化速度。供应商还建议用户在使用前根据具体工艺条件进行测试。

泽维尔-汤普森 -

美妙的体验!服务一流,产品质量超出了我的预期。