Antioxidant PEPQ Application scenarios

1. Polipropileno (PP)

Automotive parts (interior trim, bumpers), appliance housings, food containers, medical devices, fibers (non-woven fabrics)

Prevents yellowing and graying during repeated or high-temperature processing, maintaining color purity; reduces melt viscosity changes, ensuring smooth processing.

2. Polyethylene (HDPE, LLDPE)

Pipes, cable sheaths, large hollow containers (e.g., chemical drums), films. Protects materials during prolonged high-temperature processes such as extrusion, preventing degradation, maintaining stable mechanical properties, and extending the outdoor lifespan of products.

3. Plásticos de engenharia

Polycarbonate (PC): Electronic housings, headlight covers

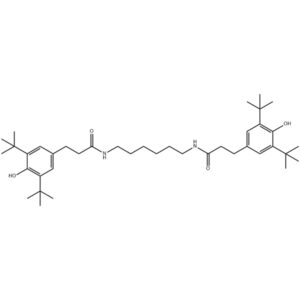

Nylon (PA): Automotive hood components, electrical connectors

PBT/PET: Electronic components, fibers

These materials have extremely high processing temperatures (often exceeding 280°C). P-EPQ provides top-level thermal stability protection, preventing yellowing and property degradation at high temperatures, making it a key additive in manufacturing high-appearance, high-performance components.

4. Outros polímeros

ABS, PS, Elastomers, Adhesives and Resins (e.g., EVA hot melt adhesives)

Used as a highly effective auxiliary stabilizer in formulations requiring good color and processing stability.

⚙️ Principais características de uso

To fully utilize P-EPQ, it’s essential to understand its key characteristics:

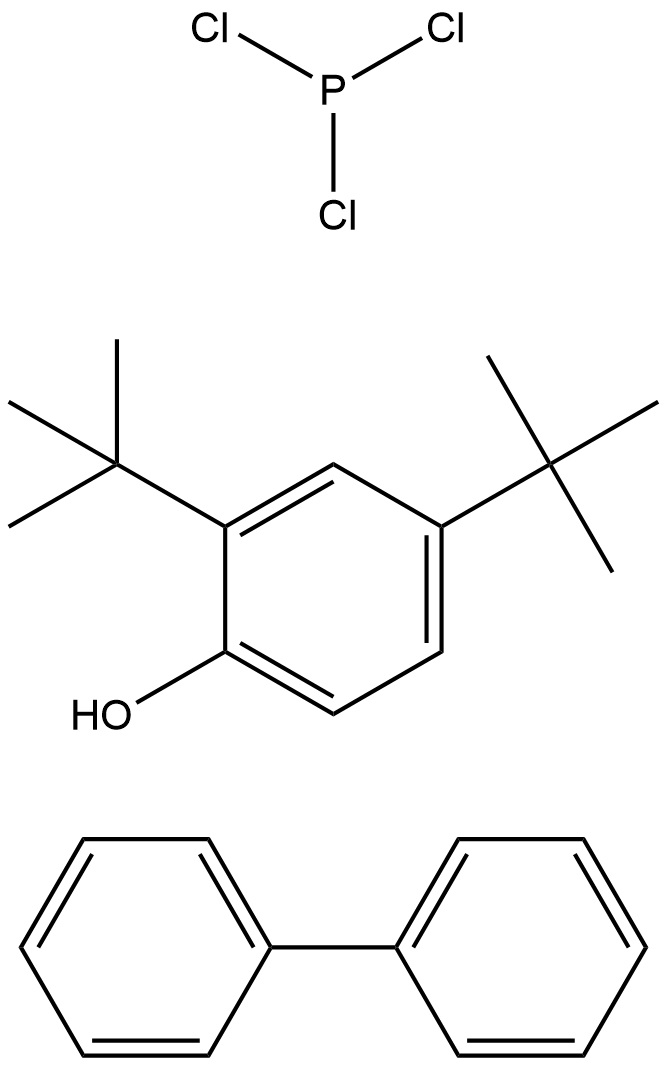

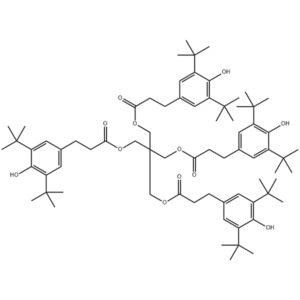

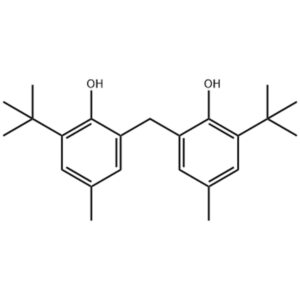

“Auxiliary” Positioning and Synergistic Effect: P-EPQ belongs to the auxiliary antioxidant class (phosphite esters). It must be used synergistically with a “primary antioxidant” (such as hindered phenolic antioxidants 1010, 1076, etc.) to form a complete stabilization system. The combination achieves a “1+1>2” effect, simultaneously ensuring processing stability (P-EPQ’s responsibility) and long-term thermo-oxidative stability (the primary antioxidant’s responsibility).

Dosage and High Efficiency: Its dosage in formulations is typically very low, generally between 0.05% and 0.25%. Even a small amount can significantly improve color and melt stability, offering high cost-effectiveness.

Why Choose It?

Compared to some traditional phosphite antioxidants, P-EPQ has a larger molecular weight and more stable structure, with higher heat resistance (>350℃) and lower hydrolysis sensitivity, making it more reliable in harsh processing conditions or in hygroscopic polymers (such as nylon).

Sophia Roberts -

Excelente serviço, respostas rápidas, logística perfeita, compras agradáveis!