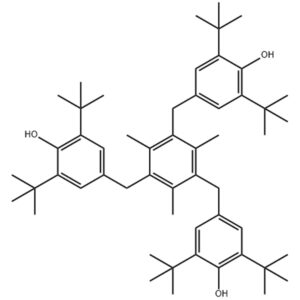

Antioxidant SEED Application scenarios

1. Nylon (PA) Fibers, Engineering Plastics, Films

• Improved Processability: Improves melt stability, reduces processing cycles, and lowers fiber breakage rate.

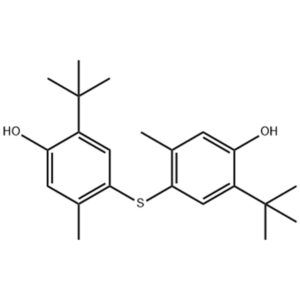

• Long-lasting Protection: Provides excellent long-term heat, UV, and oxidative aging protection.

• Improved Dyeability: Enhances color in dyed products, improves color strength, and increases fiber dyeability.

2. Polyester Materials

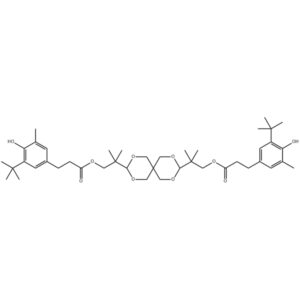

• Thermal Protection: Provides synergistic thermal protection when used in conjunction with auxiliary antioxidants (such as Revonox 608).

• Overall Stability: Improves the stability of materials during processing and use.

💡 Usage Precautions

In practical use, several key points need to be noted:

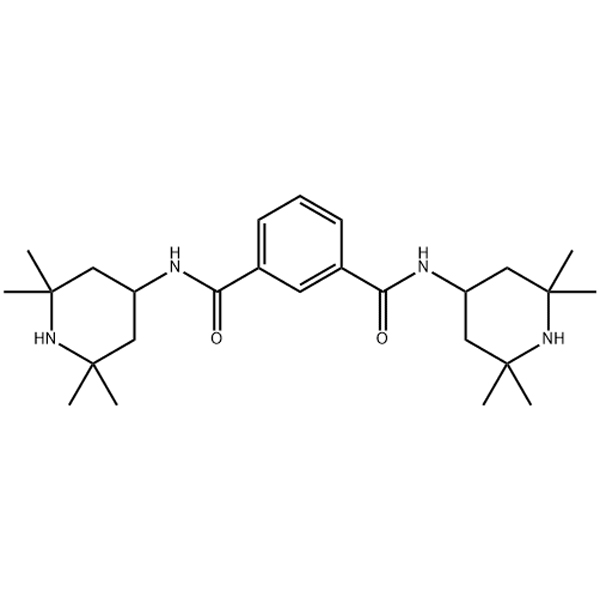

Synergistic Formulation: To achieve optimal heat and UV protection performance, it is often used in combination with secondary antioxidants (such as Revonox 608) and other light stabilizers (such as Chiguard 1033) to produce a synergistic effect.

Product Properties: This product is typically a white powder with a high melting point (approximately 270-275°C). It has very low solubility in water but is soluble in organic solvents such as dimethylacetamide.

In summary, if you are processing nylon or polyester materials, especially in areas requiring weather resistance, high temperature resistance, and color stability (such as automotive parts, outdoor fibers, and electronics), antioxidant SEED is a crucial functional additive.

William Parker –

Superb service, timely replies, hassle-free logistics, wonderful shopping!