Antioxidant DSTDP Application scenarios

1. Plastics Industry

Provides long-lasting thermo-oxidative stability, preventing degradation, discoloration, and decline in mechanical properties during processing and use.

Polyolefins (e.g., polypropylene PP, polyethylene PE), styrene polymers (e.g., ABS, PS),

Other resins.

2. Rubber Industry

As a non-polluting auxiliary antioxidant, prevents rubber products from hardening, becoming brittle, or cracking due to thermo-oxidative aging.

Various synthetic rubbers and products.

3. Oils and Lubricants

Inhibits oxidative rancidity of oils, lubricants, and greases, extending service life and maintaining performance stability.

Industrial lubricants, greases, and soaps.

4. Cosmetics and Personal Care

As an antioxidant and UV stabilizer, protects product ingredients and helps skin resist free radicals and UV damage.

Creams, lotions, and other skincare products.

💡 Core Mechanism of Action and Usage Characteristics

To understand the application of DSTDP, it’s essential to understand its two core characteristics:

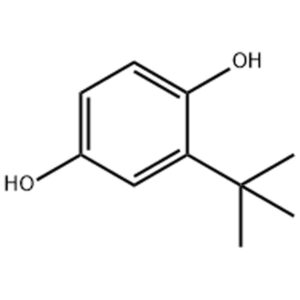

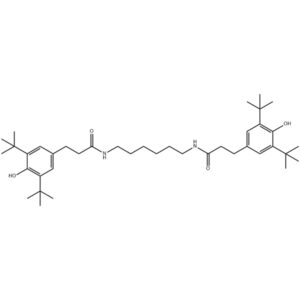

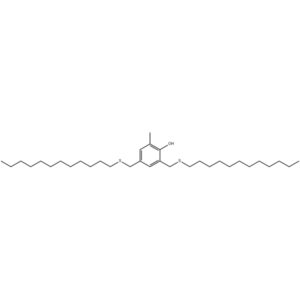

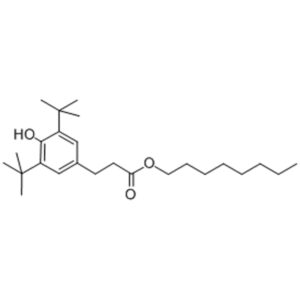

As a secondary antioxidant: It doesn’t directly capture free radicals, but rather efficiently decomposes hydroperoxides, converting them into stable alcohols, thereby interrupting the oxidation chain reaction. This function perfectly complements phenolic primary antioxidants (such as Revonox® 501) that can capture free radicals.

Synergistic Effect: When DSTDP is used in combination with phenolic primary antioxidants, the two produce a synergistic effect of “1+1>2,” significantly enhancing the overall antioxidant capacity of the material. This is a key reason for its widespread use in formulations.

Description

| Item |

Specifications |

| Appearance |

White powder |

| Melting point ℃ |

63.5~68.5 |

| Volatile % |

≤0.05% |

| Ash % |

≤0.01% |

Application:

CHLUMIAO®DSTDP is a kind of thioester auxiliary antioxidant with excellent performance. Its antioxidant effect is higher than CHLUMIAO®DLTDP, low volatility, low thermal processing loss, no pollution and no coloring. It has a synergistic effect when used together with the main antioxidants CHLUMIAO® 1010 and CHLUMIAO® 1076,CHLUMIAO® CA, etc. It is widely used in petroleum products such as polyethylene, polypropylene, ABS resin, and the general dosage is 0.1% to 1.0%.

Storage:

Avoid exposure to the sun or high temperature storage, and should be stored in a cool, dry and ventilated place to prevent moisture, water, and heat.

Package:

Use carton lined with plastic bag, net weight of each box is 25kg

Other Name:

Advastab 802;

Arbestab DSTDP;

Cyanox STDP;

Naugard DSTDP;

Plastanox STDP;

Hostanox SE 2;

Irganox PS 802;

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

When we come into contact with plastics or other polymers, we often hear about antioxidants. Perhaps also probably understand that the addition of antioxidants is to antioxidant, anti-aging, but may be a large majority of friends still do not understand the mechanism. Today, we will learn to learn the causes of aging of polymer materials, the mechanism and its solution.

What is oxidation?

Professional explanation: oxidation (oxidation), narrowly defined as the chemical reaction between oxygen and other material elements, is also an important chemical unit process. Broadly speaking, oxidation refers to the process in which a substance loses electrons (the oxidation number rises).

Common explanation: yellowing, aging, hardening, brittleness, softening, dullness, rusting and other phenomena caused by wind, sun and rain, oxygen in the air, hydrodynamic and wind erosion can be roughly categorised as oxidation.

The best example is the phenomenon of a cut apple, exposed to the air for some time, gradually turning yellow. In fact, not only apples will oxidise, our skin will also oxidise, plastic products and polymers will oxidise and age! Aging is a common process in nature, the most common around us is life from birth, growth, aging process, is the most typical of an aging process.

Corrosion of metal materials is also a kind of aging, from shiny objects into rust, until the loss of value.

The same goes for polymers. During processing and use, due to the combined effects of heat, oxygen, water, light, microorganisms, chemical media and other environmental factors, the chemical composition and structure of polymers undergo a series of changes, and their physical properties deteriorate accordingly, such as hardening, sticking, brittleness, discolouration, loss of strength, and so on, which are known as aging.

Molecular polymer aging, what will produce bad?

1, reduce mechanical properties

2, discolouration

3, reduce transparency

4, yellowing, aging

5, cracking

6, odour (alcohols, aldehydes, ketones)

—–

Polymer aging, what factors are at fault?

1, the structure of the polymer: double bond, benzene ring is not stable enough structure, easily lead to polymer decomposition, yellowing

2, polymer synthesis of residual impurities: peroxide, metal ions lead to polymer degradation, yellowing

3、Oxygen (air): the presence of oxygen, ozone caused by the decomposition of polymer

4, energy: mechanical stress, heat, ultraviolet light

5、Air pollution: NOx, SOx.

6, water, moisture: may lead to dissolution, precipitation of biological: degradation caused by biological enzymes

Why do polymers age?

Polymers form excited state molecules in the presence of heat or light. When the energy is high enough, the molecular chains break to form free radicals, which can form chain reactions within the polymer that continue to initiate degradation and may also cause cross-linking. The Culprit: Free Radicals R-

If oxygen or ozone is present in the environment, a series of oxidation reactions are also induced, resulting in the formation of hydroperoxides (ROOH), which further decompose into carbonyl groups.

If residual catalyst metal ions are present in the polymer, or if metal ions such as copper, iron, manganese, cobalt, etc., are brought in during processing or use, the oxidative degradation reaction of the polymer will be accelerated. Polymers protect against ageing.

Therefore, antioxidants have become a life-saving elixir for the materials industry!

To prevent polymer aging, you can isolate light and heat, and most importantly, add antioxidants! So here’s the point! Where to find efficient, genuine, good quality antioxidants?

Charlotte West –

Excellent service, rapid replies, hassle-free logistics, delightful shopping!