Antioxidant 1330 Application scenarios

1. Polyolefins

High-density polyethylene (HDPE), polypropylene (PP), etc. It is an excellent antioxidant, commonly used in pipes and injection-molded products, providing long-lasting thermal stability protection.

2. Engineering Plastics

Polyamide (PA), polyester (PET/PBT), ABS resin, etc. Prevents high-temperature oxidation during processing, maintaining the material’s mechanical properties and appearance.

3. Elastomers

Polyurethane (PU), natural rubber and synthetic rubber, etc. Delays the aging of rubber products and extends their service life.

4. Other Materials

Polyvinyl chloride (PVC), synthetic fibers, adhesives and coatings, etc. Used as an auxiliary stabilizer in specific formulations.

🔍 How to Choose and Use

In practical applications, the following points require special attention:

Key Application Areas: Due to its excellent thermal stability and low volatility, it is particularly suitable for products requiring high-temperature processing (such as extrusion and injection molding) or long-term use in high-temperature environments. For example, polyolefin pipes, automotive parts, and wire and cable insulation materials are typical application scenarios.

Dosage Reference: The general addition amount is small, varying depending on the resin type and requirements. For example, the recommended dosage in polyolefins is usually 0.05% – 0.5% (by weight).

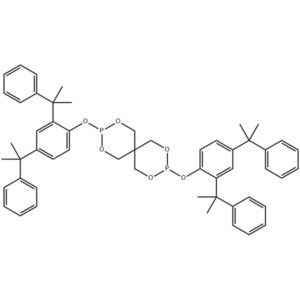

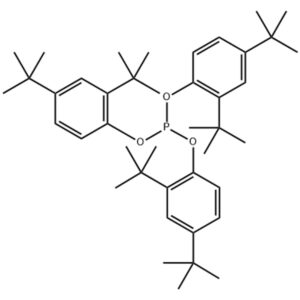

Synergistic Effect: In actual formulations, antioxidant 1330 is often used in combination with auxiliary antioxidants such as phosphites and thioesters, which can produce a significant synergistic effect and provide more comprehensive antioxidant protection.

Description

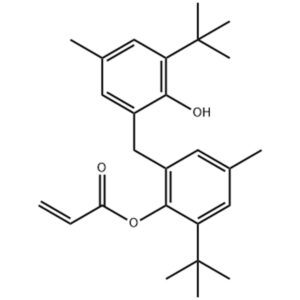

CHLUMIAO® 1330 / Irganox 1330 CAS 1709-70-2

| Specification |

Unit |

Standard |

| Appearance |

|

White powder |

| Content |

% |

≥98.00 |

| Ash |

% |

≤0.10 |

| Volatile matter |

% |

≤0.50 |

| Melting point |

℃ |

240.00-247.00 |

| Light transmittance |

|

|

| 425nm |

% |

≥96.00 |

| 500nm |

% |

≥98.00 |

CHLUMIAO® 1330 Usage

Antioxidant 1330 has excellent high-temperature processing properties, especially its resistance to hot and cold water extraction is superior to other products in the same category, coupled with non-toxic, it is favoured by the food and beverage packaging industry, and is widely used in PPR resins, as well as various packaging materials in contact with pharmaceuticals, food, beverages and drinking water.

1. PP, PE cable insulation, antioxidant for film materials – effective insulation properties

2. good extraction resistance on PP water quenched blown film lines

3. good performance in controlling polyolefin degradation

4. no absorption by polyolefin fillers

5. high resistance to oxidative degradation

6. light stabiliser – can be combined with hindered amine light stabilisers and UV absorbers

7. used without metal passivators

8. Suitable for use in SBS, rubber, polyamide, polyester and synthetic fibres

9. high molecular weight, low volatility

10. Biologically inert

11. FDA approved for all polymer and polymer blend applications with indirect contact with food

12. waterproof and oil extractable

13. no unusual odour, no taste

14. protects a wide range of polymers during processing and long-term applications

15. good compatibility with most polymer additives

16. retains effectiveness when fillers and other modifiers are used

17. non-staining, non-staining

18. reduces water carry-over in film production

19. electrically neutral: its zero dipole moment is an added advantage in electrical applications

20. low volatility and non-migration

The high molecular weight of CHLUMIAO® 1330 makes it less likely to evaporate from the polymer during processing and high temperature applications. Thermogravimetric analysis (TGA) results show no significant weight loss until reaching 320-330°C (indicative of volatility).

Antioxidant 1330 Packing

25KG carton,20KG PE bag

Handling and storage of Antioxidant 1330

Please consult the safety data sheet before handling or using this product.

Shelf life is one year if stored in a dry area below 25°C in a suitable manner.

Contact Us Now!

If you need Price, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.

Lillian Fox –

Exceptional quality and fast shipping! The product exceeded my expectations, and I’m thoroughly impressed with the overall experience.