Application scenarios

1. Polymer Materials and Industry (Main Application)

BHT is an indispensable antioxidant in the rubber and plastics industries, used to prevent materials from aging, yellowing, and becoming brittle due to heat, oxygen, and ultraviolet radiation during processing, storage, and use.

Plastics: Widely used in polyethylene (PE), polypropylene (PP), polystyrene (PS), ABS resin, polyvinyl chloride (PVC), etc. It is especially prevalent in polyolefins.

Rubber: Used in natural rubber and various synthetic rubbers (such as SBR, BR) products to protect them from oxidation-induced loss of elasticity and cracking (crazing).

Elastomers and Adhesives: Used as a stabilizer in adhesives, sealants, and other products.

2. Petroleum Products and Fuel Industry

BHT effectively inhibits the oxidation of hydrocarbons in oils, extending their service life.

Lubricating Oils and Greases: Added to engine oils, hydraulic oils, industrial gear oils, etc., to prevent oil oxidation and deterioration, the formation of sludge and acidic substances, and to protect equipment.

Fuel Oil: Used in gasoline, jet fuel, etc., as a stabilizer to prevent gum formation during storage and keep the fuel system clean.

3. Food Industry (as a Food Additive)

BHT is approved for use as a food additive (antioxidant), INS number 321. It is added directly to foods with high fat content or migrates indirectly into food through packaging materials to delay rancidity and extend shelf life.

Food Applications: Fried foods, instant noodles, baked goods, breakfast cereals, dehydrated potato chips, sausages, dried seafood, etc.

Packaging Materials: Commonly used in food packaging plastics, waxed paper, rubber gaskets, etc., exerting its effect through indirect migration.

Note: In recent years, due to concerns about health effects, the use of BHT in food has been subject to stricter restrictions in regions such as the EU. In some areas, it has been partially replaced by safer antioxidants (such as BHA, TBHQ, and Vitamin E), but its use is still permitted within prescribed limits in many parts of the world.

4. Animal Feed Industry

Similar to its food applications, BHT is added to animal feed (especially oil-rich feeds) to prevent the oxidation and rancidity of fats and vitamins during storage, thus preserving the feed’s nutritional value and palatability.

5. Cosmetics and Personal Care Products

BHT is used as an antioxidant in cosmetics, protecting oils, fragrances, and other ingredients from oxidation and preventing discoloration, changes in taste, and spoilage.

Applications: Lipsticks, lip balms, skincare products, hair oils, hair dyes, etc.

Note: Similarly, in the cosmetics industry, due to safety concerns and consumer preferences (a pursuit of “natural” ingredients), its use is gradually decreasing and being replaced by vitamin E (tocopherol), etc.

6. Other Industrial Uses

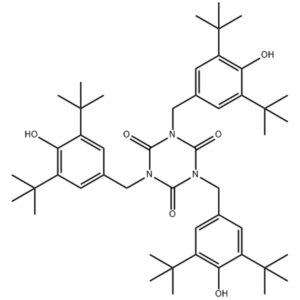

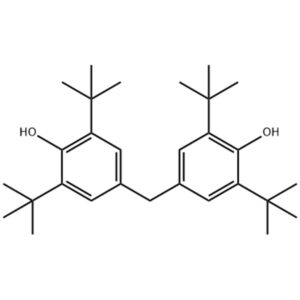

Chemical Intermediate: BHT itself is also an important chemical intermediate, used in the synthesis of other more complex antioxidants (such as antioxidants 1010, 1076, etc.).

Electronic Materials: Also used in certain specialty inks and industrial greases.

Summary and Characteristics

Advantages: High efficiency, low cost, and good stability have made it one of the most widely used antioxidants over the past few decades.

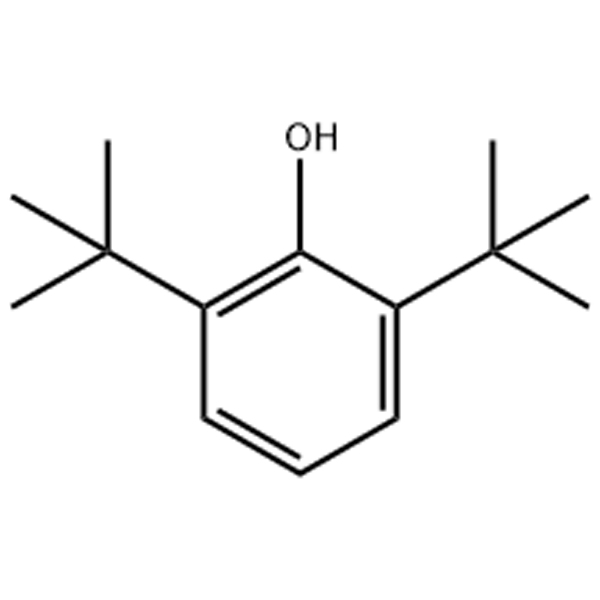

Form: Typically a white or pale yellow crystalline powder.

Trends: In the food and cosmetics industries, the use of BHT is being partially replaced or subject to stricter restrictions due to potential health controversies and consumers’ pursuit of “clean labels.” However, in industrial applications (plastics, rubber, fuels), it still holds a very important position due to its excellent cost-effectiveness and stability.

Core Function: Regardless of the application, the core function of BHT remains as a free radical scavenger, delaying or preventing the auto-oxidation process of organic matter (polymers, oils, fuels, etc.), thereby protecting product performance and extending its service life.