描述

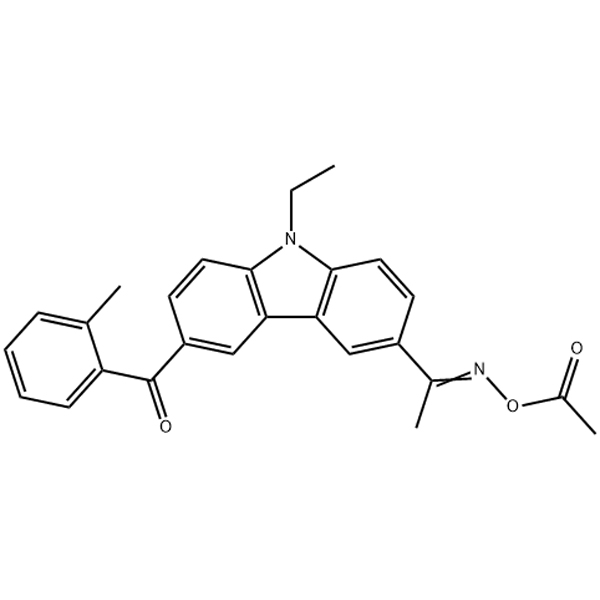

光引发剂 OXE-02

同义词: 1-(O-乙酰氧基肟)-1-[9-乙基-6-(2-甲基苯甲酰基)-9H-咔唑-3-基]乙酮;CHLUMINIT® OXE-02; Irgacure OXE-02

化学文摘社编号: 478556-66-0

分子式C26H24N2O3

375 纳米 LED

一般信息:

OXE-02 是一种肟酯类光引发剂,具有高光敏性和宽吸收峰。OXE-02 可与 LED 配合使用。OXE-02 既可用于无色体系,也可用于有色体系,具有毒性低、气味小和环保等特点。

规格:

| 外观 |

白色至淡黄色粉末 |

| 纯净 |

≥99% |

| 吸收峰值 |

295/368/380/400 |

| 挥发性成分 |

≤0.5% |

| 熔点 |

122-129°C |

CHLUMINIT® OXE-02 的使用方法:

从建筑装饰到电子设备制造,从日常印刷品到高端精密仪器的生产,紫外线涂料、紫外线油墨和紫外线粘合剂等材料都发挥着不可或缺的作用。光引发剂 OXE-02 在这些材料中的应用既广泛又重要。以紫外线涂料为例。在建筑外墙涂料中,这些涂料不仅干燥速度快,而且具有出色的耐候性。光引发剂 OXE-02 在引发聚合反应方面起着关键作用,可使涂层快速固化,形成坚固美观的涂层。同样,用于制造电子设备的 UV 油墨也需要高精度的印刷效果。光引发剂 OXE-02 可确保油墨在紫外线下精确固化,从而保证印刷图案的清晰度和耐久性。

值得一提的是,它在紫外线粘合剂领域也表现出色。例如,在汽车零件组装中,需要快速固化和高强度的粘合剂,紫外线粘合剂是首选。光引发剂 OXE-02 是这种粘合剂发挥其强大功能的核心因素。此外,它在防腐剂和助焊剂中也发挥着不可替代的作用。在对长期暴露在恶劣环境中的金属产品进行防腐保护时,含有光引发剂 OXE-02 的缓蚀剂可以形成一层致密的保护膜,有效防止金属被外部环境侵蚀。

在实际使用中,对光引发剂 OXE-02 的用量有严格的要求。根据大量的实验数据和工业实践,推荐用量为 0.5-5%(w/w)。这个用量范围不是随意设定的,而是反复试验的结果。当用量低于 0.5% 时,聚合反应可能无法有效启动,导致产品性能不达标。例如,UV 涂层可能无法完全干燥,导致附着力差。当用量超过 5% 时,不仅成本会增加,还可能产生一些负面影响。例如,过度聚合可能会使产品变脆,影响其柔韧性和耐用性。

在不同的应用场景中,该用量范围还会受到其他因素的影响,如紫外光强度、照射时间、环境温度等。假设 UV 涂层是在高温环境下使用,由于温度对反应速度的影响,光引发剂 OXE-02 的用量可能需要稍作调整,适当减少用量,以避免反应过度引起的质量问题。相反,在低温环境或紫外线强度较弱的情况下,可能需要略微增加用量,以确保反应正常进行。这些都是在实际生产过程中需要考虑的复杂因素,这也进一步凸显了准确控制光引发剂 OXE-02 用量的重要性。

包装:

1 公斤/袋

存储:

存放在阴凉干燥处,避免阳光直射。

立即联系我们!

如果您需要价格,请在下表中填写您的联系信息,我们通常会在 24 小时内与您联系。您也可以给我发电子邮件 info@longchangchemical.com 请在工作时间(UTC+8 周一至周六,上午 8:30 至下午 6:00)或使用网站即时聊天工具获得及时回复。

OXE-02 is a

highly efficient radical-type photoinitiator belonging to the

alkoxyphosphine family. Its key characteristics include

long absorption wavelength, high photolysis efficiency, and rapid curing speed, coupled with

outstanding deep-curing and yellowing resistance. This makes it particularly suitable for applications demanding high curing thickness, fast curing speed, and color stability.

1. UV-LED Curing Systems

This represents OXE-02's most significant and fastest-growing application segment.

- Reason: Traditional mercury lamps emit broad-spectrum UV radiation, whereas UV-LED light sources emit monochromatic light at specific wavelengths (typically 365nm, 385nm, 395nm, or 405nm). OXE-02 exhibits strong absorption in the long-wave UVA region (particularly 350-420nm), perfectly matching the emission wavelengths of mainstream UV-LED light sources.

- Application Products:

- UV-LED Inks (e.g., inkjet printing, flexographic printing)

- UV-LED Coatings

- UV-LED Adhesives

2. White and Colored Systems

OXE-02 is a critical component in white coating and ink formulations.

- Reason: White pigments like titanium dioxide strongly scatter and block short-wave UV light, preventing penetration into deeper coating layers. OXE-02's long-wave absorption properties enable it to penetrate the pigment barrier, effectively initiating curing at the coating base. This prevents “surface dry, base wet” issues and ensures excellent adhesion.

- Application Products:

- UV topcoats for white goods (e.g., refrigerators, washing machines)

- White printing inks for paper and plastics

- Colored paint systems containing other high-opacity pigments

3. Thick Coatings and Composites

OXE-02 is ideal for applications requiring single-pass curing of thick coatings.

- Reason: Long-wave UV light penetrates deeper than short-wave UV. OXE-02 effectively absorbs this long-wave energy, ensuring uniform photopolymerization throughout the coating thickness for complete curing.

- Application Products:

- Wood filler putty

- Electronic Component Encapsulation Adhesives

- Glass Fiber Reinforced Composites (e.g., FRP)

4. Applications Requiring Yellowing Resistance

Compared to some traditional initiators (e.g., ITX), OXE-02 and its photolysis products exhibit lighter coloration, thereby better preserving the original hue of cured materials.

- Reason: Its molecular structure and photolysis products are less prone to generating chromophores.

- Application Products:

- High-transparency varnishes and topcoats

- Overprint varnishes requiring high color fidelity

- Plastic coatings demanding high color stability (e.g., PET, PMMA)

5. 3D Printing (UV Curing)

In UV-curing 3D printing, OXE-02 serves as a critical photoinitiator.

- Reason: Many desktop and industrial LCD/DLP 3D printers utilize 405nm UV-LEDs as light sources. OXE-02 exhibits high compatibility with this wavelength, ensuring rapid and precise resin curing with superior dimensional accuracy.

- Application Products:

- LCD (mask exposure) and DLP (digital light processing) 3D printing photopolymer resins.

Key Advantages Summary

- Long-Wavelength Absorption: Perfectly matches UV-LED light sources (365-405nm).

- Deep Curing Capability: Effectively cures white, high-opacity pigment systems and thick coatings.

- Low Yellowing: Yields color-pure cured products with superior aging resistance.

- High Photolysis Efficiency: As a Type I initiator, it directly decomposes into active radicals upon photon absorption without requiring co-initiators, enabling rapid curing.

- Excellent Compatibility: Compatible with most acrylic oligomers and monomers.

In summary,

OXE-02 is a high-performance, indispensable photoinitiator in modern UV curing technology, particularly UV-LED curing systems, widely applied in premium printing, coatings, adhesives, and emerging 3D printing applications.

评价

目前还没有评价