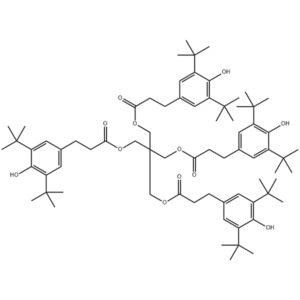

Antioxidant 9228 Application scenarios

1. Plásticos de uso geral

• Polypropylene (PP): Maintains stable color and melt index during multiple extrusion processes.

• Polyethylene (PE, LDPE, LLDPE): Provides excellent color and melt flow stability.

• Polystyrene (PS, HIPS).

2. Plásticos de engenharia

• Polycarbonate (PC): Meets high-temperature processing requirements, preventing degradation and discoloration.

• Polyamide/Nylon (PA).

• Polyesters (PET, PBT).

• Polyphenylene oxide (PPO), Polyphenylene sulfide (PPS).

3. Special High-Performance Materials

• Polyether ether ketone (PEEK): Meets the anti-degradation requirements of this special material during high-temperature processing.

• Other high-temperature engineering plastics with processing temperatures exceeding 280°C.

💡 Important Application Scenarios

In addition to being used as a single additive, it also plays a key role in the following specific scenarios:

• Application in BOPP films: Antioxidant 9228 is often compounded with primary antioxidants (such as antioxidant 1010) as a composite additive for biaxially oriented polypropylene (BOPP) films, effectively improving film processing stability, preventing cross-sectional yellowing, and enhancing product quality.

• Synergistic application in special engineering plastics: For special engineering plastics with extremely high processing temperatures (often exceeding 320°C), such as PPA, PA6T, and LCP, antioxidant 9228 can be used synergistically with specific phenolic primary antioxidants (such as 1790) to meet demanding processing thermal stability requirements.

Liam Fitzgerald -

Serviço de primeira linha, respostas extremamente rápidas, logística tranquila, compras agradáveis!