Photoinitiator 184 Application scenarios

1. Coatings

Wood coatings (e.g., wear-resistant floor coatings, furniture coatings, UV primers), plastic coatings (e.g., mobile phone casings, automotive interiors, appliance panels), metal coatings (e.g., decorative metal panels, canned food packaging), paper varnishes

Wood, plastic, metal, paper

2. Inkten

Offset printing inks, screen printing inks, flexographic printing inks, inkjet printing inks

Packaging materials, labels, printed products

3. Lijmen

Various UV-curable adhesives

Bonding of glass, plastics, and metals

4. Electronics and Emerging Fields

Electronic product encapsulation materials, optical fiber coatings, 3D printing photopolymer resins

Electronic components, optical fibers, 3D printed models

Beschrijving

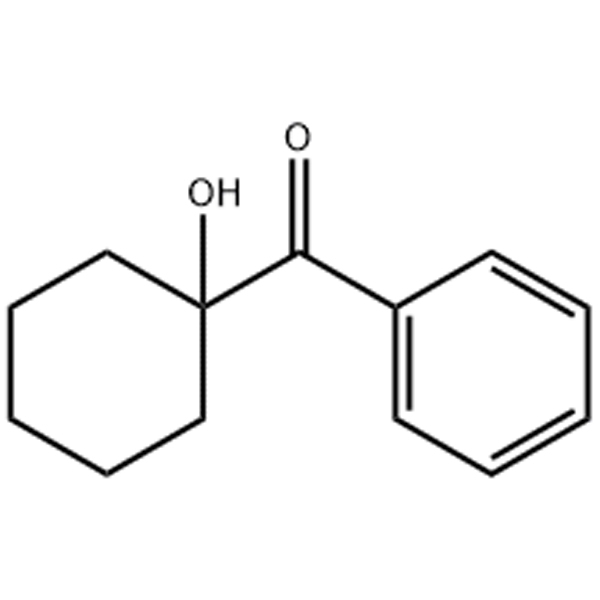

Fotoinitiator 184 / irgacure 184 / Omnirad 184 CAS 947-19-3

Chemische naam: 1-Hydroxycyclohexyl fenylketon

Synoniem: 184;Omnirad 184;Fotoinitiator CPK;DOUBLECURE 184;Speedcure 184

CAS-nr: 947-19-3

MF: C13H16O2

Standaard

| Item |

Specificaties |

| Uiterlijk |

Witkristallijn |

| Assay |

≥99,0% |

| Smeltpunt |

46.0~50.0℃ |

| Verlies bij drogen |

≤0.1% |

| As |

≤0.2% |

| Kleur |

≤50 hazen |

Gebruik:

Irgacure 184 is een vrije radicaal type I fotoinitiator. Deze kleine molecule speelt een essentiële rol in de grote arena van lichtuitharding. Als een bekwame vakman voert het unieke magie uit in de wondere wereld van UV-licht.

Een overzicht van de ontwikkeling van lichtuithardingstechnologie is een prachtig epos dat verweven is met menselijke vindingrijkheid en technologie. In de begindagen waren mensen op het gebied van oppervlaktebehandeling en -bewerking van materialen altijd op zoek naar efficiëntere methoden met een hogere kwaliteit. Traditionele processen waren in veel opzichten beperkt en de komst van UV-lichtuithardingstechnologie was als een lichtstraal die ongekende mogelijkheden bracht. Irgacure 184 betrad ook het historische podium en werd een van de sleutelfactoren achter de ontwikkeling van deze technologie.

De magie van Irgacure 184 ligt in de extreem hoge absorptie-efficiëntie voor UV-licht. Wanneer het wordt blootgesteld aan UV-licht met een golflengte van ongeveer 365 nm, werkt het als een precieze energievanger die gulzig lichtenergie absorbeert en vrije radicalen produceert. Deze vrije radicalen zijn als energetische kleine deeltjes die snel de polymerisatiereactie in gang zetten. Dit vermogen maakt het perfect voor coatings, inkten en lijmen van lage tot gemiddelde dikte, waar het een snelle uitharding bereikt, alsof het deze materialen de magische kracht van instant stolling geeft.

Irgacure 184 blinkt uit in vele UV-uithardingstoepassingen.

Het is extreem veelzijdig op het gebied van lichtuithardende coatings. Irgacure 184 blinkt uit, of het nu wordt gebruikt op het rustieke gestructureerde oppervlak van hout, het harde gestructureerde oppervlak van metaal of de gladde oppervlakteafwerking van kunststof. Neem bijvoorbeeld de productie van meubels, waar het oppervlak van het hout van een beschermende en decoratieve laag moet worden voorzien. Met UV-uithardende coatings met Irgacure 184 hardt de coating snel uit onder UV-licht. Dit verhoogt niet alleen de hardheid van de coating, waardoor het meubel beter bestand is tegen krassen tijdens dagelijks gebruik, als een sterk pantser, maar het verbetert ook aanzienlijk de slijtvastheid. Tegelijkertijd ontbindt het snel en veroorzaakt het geen problemen met vergeling. Voor coatings die een hoge transparantie vereisen, zoals de glazen oppervlaktecoatings van high-end vitrines, zorgt het ervoor dat de coating helder en transparant blijft, waardoor het perfecte weergave-effect van de tentoongestelde voorwerpen behouden blijft.

Irgacure 184 is ook onmisbaar voor UV-uithardende inkten. Het is een uitstekende commander die het uithardingsproces van inkten leidt, vooral bij inktsystemen met lichtere kleuren zoals transparant en wit. Neem als voorbeeld hoogwaardige drukwerkproducten, zoals prachtige kunstalbums of hoogwaardige cosmetische etiketten. De voordelen van UV-uithardende inkten met Irgacure 184 op het gebied van uithardingssnelheid en efficiëntie zijn volledig aangetoond. De inkt droogt snel en hardt snel uit, met een sterk verbeterde hechting, zodat hij niet gemakkelijk van het bedrukte materiaal afbladdert. Bovendien zorgt de verbeterde slijtvastheid en waterbestendigheid ervoor dat het drukwerk zijn heldere kleuren en duidelijke patronen lang behoudt, zelfs na gebruik of blootstelling aan vocht, alsof er een duurzame beschermende film op de bedrukte inhoud is aangebracht.

Irgacure 184 heeft unieke voordelen voor UV-lijmen. Het is de onbetwiste ster op het gebied van het verlijmen van transparante materialen. Stelt u zich de verlijming voor van glazen lenzen bij de productie van hoogwaardige optische apparaten, die een extreem hoge precisie en transparantie vereisen. UV-lijmen met Irgacure 184 harden snel uit onder UV-licht, en na uitharding vergelen ze niet en zijn ze extreem transparant. Het is als het bouwen van een onzichtbare maar sterke brug tussen de lenzen, die ervoor zorgt dat de optische eigenschappen van het optische apparaat niet worden beïnvloed en die een sterke garantie biedt voor een nauwkeurige optische beeldvorming.

Irgacure 184 is ook zeer sterk op het gebied van 3D-fotoresines. Het kan worden gebruikt als een van de belangrijkste initiatoren voor 3D printing fotoresinen, vooral voor het printen van onderdelen die fijne structuren en een hoge transparantie vereisen. Bijvoorbeeld bij het printen van medische modellen, voor sommige modellen van menselijke organen waarbij de interne structuur zichtbaar moet zijn, zijn een hoge transparantie en de weergave van fijne details essentieel. De efficiënte uithardingseigenschappen van Irgacure 184 kunnen de uithardingstijd aanzienlijk verkorten, waardoor het printproces efficiënter wordt. Tegelijkertijd zorgt het ervoor dat de details van het geprinte product perfect worden gereproduceerd, met elk minuscuul bloedvat of weefseltextuur duidelijk zichtbaar, waardoor een nauwkeurig model ontstaat voor medische diagnose en onderwijs.

Irgacure 184 is ook onvervangbaar op het gebied van coatings voor elektronische materialen. De geringe vergeling en lage geur zijn vooral belangrijk in toepassingen zoals coatings voor optische vezels en beschermende films voor elektronische componenten. Optische vezels zijn een belangrijk onderdeel van moderne communicatie en hun coatings moeten ervoor zorgen dat de optische eigenschappen van de vezels niet worden aangetast. Door het gebruik van Irgacure 184 kan de optische vezelcoating de transparantie behouden en tegelijkertijd de stabiliteit verbeteren, waardoor de stabiele transmissie van optische signalen in de optische vezel wordt gegarandeerd. Voor de beschermende film van elektronische componenten beschermt het niet alleen de componenten tegen de externe omgeving, maar heeft het ook geen invloed op de prestaties van elektronische apparatuur door geur of vergeling, waardoor een stabiele werking van elektronische apparatuur wordt gegarandeerd.

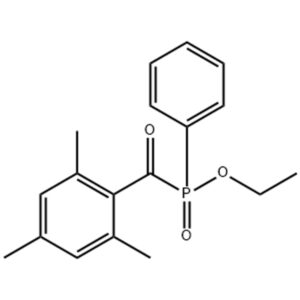

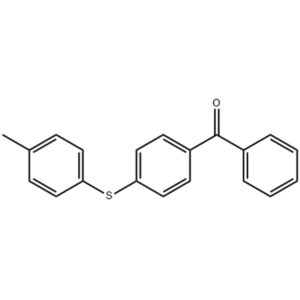

Het is vermeldenswaard dat de fotoinitiator Irgacure 184 vaak wordt gebruikt in combinatie met andere initiatoren, zoals TPO of 1173. Het is als een prachtig ensemble, waarbij elke initiator zijn eigen unieke toon heeft. Ze werken samen om de uithardingssnelheid en fysische eigenschappen van het product te optimaliseren. Achter dit mengsel gaan complexe chemische principes schuil. Het synergetische effect van de verschillende initiatoren kan elkaars tekortkomingen compenseren en een sterkere uitharding bewerkstelligen, net als het creëren van een universele sleutel die de deur kan openen naar meer soorten toepassingen voor lichtuithardende materialen.

Laten we een nieuwe hypothese maken: als in de toekomst voor de productie van virtual reality (VR) en augmented reality (AR) apparaten lichtuithardende behandeling van sommige speciale optische lenzen en displaymaterialen nodig is, zal Irgacure 184 dan een grotere rol kunnen spelen? Deze apparaten stellen extreem hoge eisen aan materiaaltransparantie, brekingsindex en optische stabiliteit. De geringe vergeling en hoge transparantie-eigenschappen van Irgacure 184 kunnen misschien aan deze veeleisende voorwaarden voldoen door verdere verbetering en combinatie met nieuwe initiators. Dit kan leiden tot nieuwe doorbraken in de prestaties van VR- en AR-apparaten, zoals het verbeteren van de helderheid van het display en het verminderen van beeldvervorming, waardoor gebruikers een meeslependere ervaring krijgen en de ontwikkeling van deze geavanceerde technologie wordt gestimuleerd.

Pakket: 20 kg/karton.

Opslag:

Wordt bewaard in een droog, schoon magazijn met goede ventilatie.

Vermijd blootstelling aan licht en verwarming.

Het product beschermen tegen lekkage, regen en insolatie tijdens transport.

Neem nu contact met ons op!

Als je Price nodig hebt, vul dan je contactgegevens in op het formulier hieronder. We nemen dan meestal binnen 24 uur contact met je op. Je kunt me ook een e-mail sturen info@longchangchemical.com tijdens kantooruren (8:30 tot 18:00 UTC+8 ma. ~ za.) of gebruik de live chat op de website voor een snel antwoord.

Beoordelingen

Er zijn nog geen beoordelingen.