Antioxidant 702 Application scenarios

1. Plastiche e resine sintetiche

· Polyolefins: This is the primary application area, especially in applications requiring high thermal stability.

– Polypropylene: Crucial in the processing and long-term thermal aging of PP (especially fibers, thin-walled products, automotive parts, and appliance housings), effectively preventing yellowing, embrittlement, and degradation of mechanical properties.

– Polyethylene: Used in HDPE, LDPE, and LLDPE, such as pipes, cable sheaths, films, and containers, improving their long-term thermal stability.

- Materiali plastici per l'ingegneria:

– ABS, PS, AS: Prevent oxidative degradation and discoloration during processing and exposure to light.

– Polyamides: Such as PA6 and PA66, improving their thermal stability during melt processing.

– Polycarbonate, PBT, PET: Provide processing stability and some long-term thermal stability.

– Elastomers: Such as thermoplastic elastomers, protecting them from thermal oxidation.

2. Adesivi e sigillanti

Used in hot melt adhesives and reactive adhesives to prevent oxidation and deterioration during high-temperature application or use.

3. Rubber Industry

Although less commonly used in sulfur vulcanization systems (potentially interfering with vulcanization), it can be used as an anti-thermal-oxidative aging agent in some unsaturated rubber (such as SBR, BR) non-vulcanized or light-colored products.

4. Oils and Lubricants

As an additive to petroleum products such as lubricating oils, greases, transformer oils, and hydraulic oils, it prevents oxidation and rancidity, viscosity increase, and sediment formation at high temperatures, extending their service life.

5. Materiali a contatto con gli alimenti

Due to its relatively high safety (approved for use in food contact materials in many countries and regions), it can be used in food packaging plastics (such as PP, PE films, containers) to prevent polymer degradation and meet regulatory requirements.

6. Other Polymer Products

Synthetic Fibers: Provides thermal stability protection during spinning.

Rivestimenti e vernici: Acts as a stabilizer for resin components, especially in coatings requiring baking.

Main Functions and Features

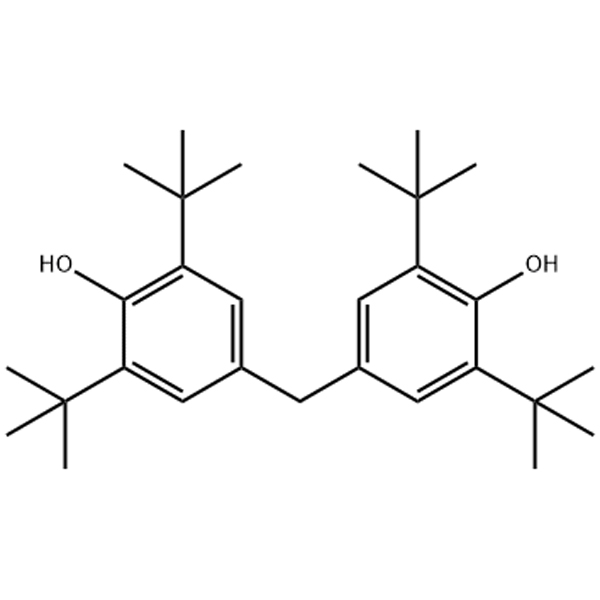

• High-efficiency primary antioxidant: Captures free radicals and interrupts oxidation chain reactions.

• Processing stabilizer: Provides protection under high-temperature conditions during polymer melt processing (such as injection molding, extrusion, and blow molding).

• Long-term heat stabilizer: Provides continuous anti-aging protection during long-term product use.

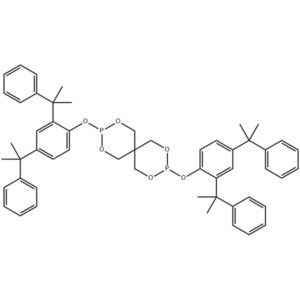

• Synergistic effect in combination: Often used in combination with auxiliary antioxidants (such as phosphites, such as Irganox 168) to produce a synergistic effect of “1+1>2”, which can more effectively decompose hydroperoxides and provide a comprehensive stabilization solution.

• Low volatility and extraction resistance: Large molecular weight, not easily volatilized or migrated, suitable for long-term protection.

Benjamin Carter -

Servizio eccellente, risposte rapide, logistica efficiente, acquisti meravigliosi!