Skenario aplikasi

1. Electrolytic Copper Foil Production

Used as an additive in the production of high-performance electrolytic copper foil for lithium batteries.

It refines grain size and smooths the copper foil surface. In specific formulations, the dosage can be as low as 2.0 mg/L.

2. Plated Through-Hole Plating for Printed Circuit Boards (PCBs)

Used as an accelerator in plated through-hole plating of PCBs (especially aluminum-based copper-clad laminates) to improve deep plating capability and coating reliability.

In a specific base plating solution, adding 9 mg/L significantly improves deep plating capability and allows the coating to pass the thermal shock test.

3. Copper Interconnects in Electronic Devices

In the manufacturing of microelectronic devices such as semiconductors, it can be used as an accelerator for the electrochemical deposition of copper to form interconnects.

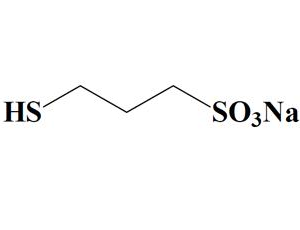

Studies have shown that replacing traditional SPS with DPS can reduce the resistivity and surface roughness of the resulting copper film.

4. Acid Copper Plating Brightener

Used as a brightener in (dye-free) acid copper plating processes to improve the brightness and surface smoothness of the plating layer.

Its high-temperature performance is considered stronger than similar products (such as SPS), and it can broaden the bright plating range in low-current density areas. Suppliers also directly label it for use as a brightener in copper electroplating.

5. Plated Through-Hole Plating of Thin Dielectric Layers in Printed Circuits

Studied as an additive/accelerator to address technical challenges in plated through-hole plating of high-density, thin printed circuit boards.

Studies show that its effect varies with concentration: at low concentrations it acts as an accelerator, while at high concentrations it may become an inhibitor.

Ulasan

Belum ada ulasan.