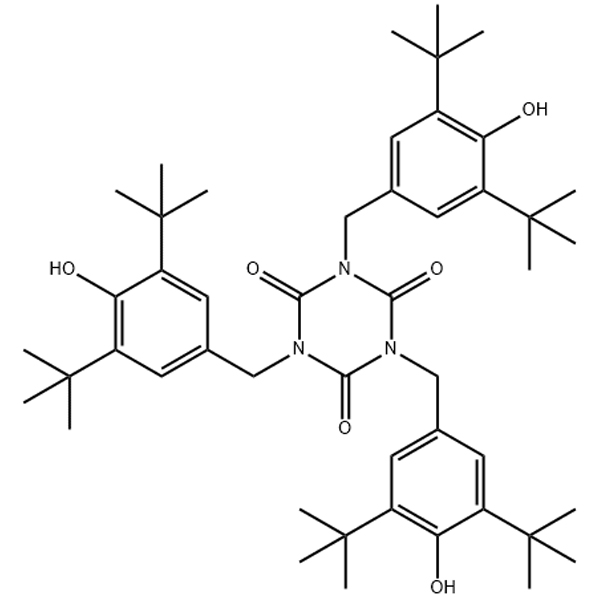

Antioxidant 3114 Application scenarios

1. Poliolefin

Thermo- and oxygen-stable, light-stable.

The most commonly used and effective material. Primarily used in polyethylene (PE) and polypropylene (PP) to extend their service life.

2. Engineering Plastics and Resins

Prevents thermal oxidative degradation. Used in polystyrene (PS), ABS resin, polyester (PET/PBT), polyamide (nylon), polyvinyl chloride (PVC), polyurethane (PU), etc.

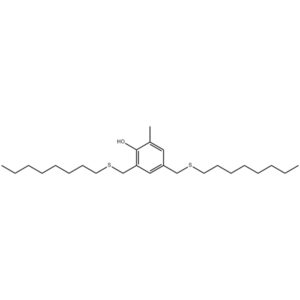

3. Rubber and Elastomers

Anti-aging, maintains elasticity. Used in various synthetic rubbers and elastomers to prevent performance degradation caused by oxidation.

4. Other Specialty Materials

Provides processing and long-term stability. Used in adhesives, coatings, synthetic fibers, lubricants, etc.

Summary and Application Recommendations

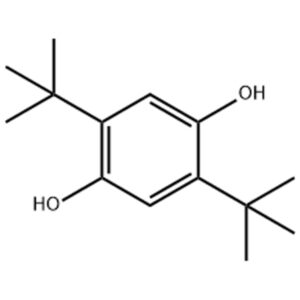

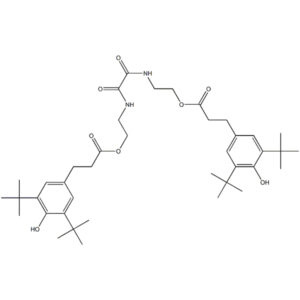

In summary, antioxidant 3114 is a versatile, stable, and particularly suitable primary antioxidant for high-quality polymer products requiring low volatility and long-term stability.

When selecting, you can refer to the following approach:

· Determine the substrate: First, confirm whether your base material is polyolefin (PP/PE) or one of the other plastics or rubbers mentioned above.

· Specific requirements: Assess the product’s long-term thermal stability, UV resistance, and extractability (e.g., resistance to water or detergent contact).

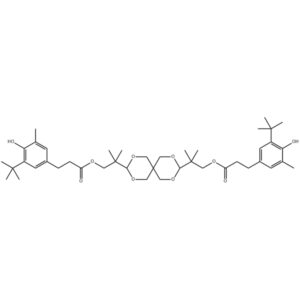

· Formulation design: Consider using antioxidant 3114 as the primary antioxidant, combined with secondary antioxidants (e.g., 168) to create a highly effective and stable system. For outdoor products, it is recommended to also add a UV absorber.

· Compliance verification: If the product involves food contact or is used in specific industries, a rigorous regulatory compliance review is essential.

Vivian Stone -

Layanan luar biasa, balasan cepat, logistik yang efisien, belanja yang menyenangkan!

Elena Brooks -

Layanan luar biasa, balasan tepat waktu, logistik yang efisien, belanja yang luar biasa