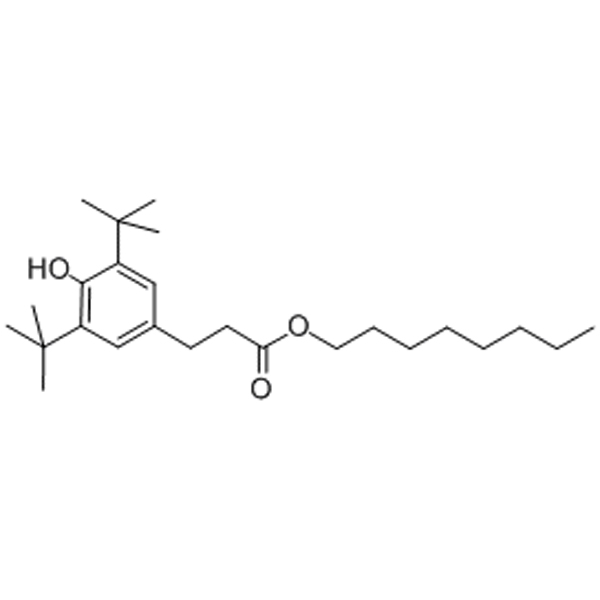

Antioxidant 1135 Application scenarios

1. Polymer Materials

Polyurethane (PU) flexible foam, polyols, adhesives, coatings, etc.

Prevents peroxide formation during storage, prevents “scorching” during processing, reduces product fogging and fabric discoloration.

2. Rubber and Lubricants

Rubber products, lubricants, fuel oils Delays oxidation and extends service life.

3. Other Industrial Fields

Gasoline (fuel), textiles, cosmetics, food industry (research purposes)

Prevents fuel gumming, protects fibers, stabilizes cosmetic ingredients, and is being researched for use in food preservation.

🧪 Polymer Materials Field (Core Application)

This is the most important and classic application area for antioxidant 1135.

Polyurethane (PU) systems: This is its most prominent application. Adding antioxidant 1135 to polyurethane flexible foam production prevents the formation of peroxides in the raw material polyether polyol during storage and effectively avoids the “scorching” phenomenon caused by high-temperature oxidation during the foaming process. Its low volatility also helps reduce fogging on the surface of products such as automotive interiors.

Processing advantages: As a liquid antioxidant, it can be pumped, allowing for precise addition and mixing at any stage before, during, or after polymerization, especially suitable for emulsion polymerization and other processes. A typical recommended addition amount is 0.15% to 0.5%.

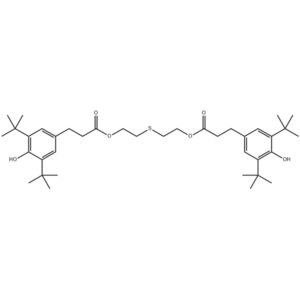

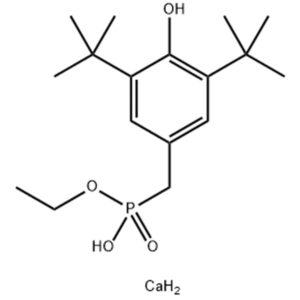

Synergistic use: To obtain more comprehensive stabilization effects, it is often used synergistically with other additives such as phosphites and light stabilizers (such as UV absorbers).

Isabella Monroe -

Pengalaman bintang lima di sekelilingnya! Produknya persis seperti yang dijelaskan, dan layanan pelanggannya luar biasa. Sangat puas!