Polythiol PM839 Anwendungsszenarien

1. Epoxidharz-Härtungsmittel/Beschleuniger

Als flüssiges Aushärtungsmittel zeichnet es sich durch seine helle Farbe und geringe Toxizität aus.

2. Schnell härtendes System

Erzielt außergewöhnlich schnelle Aushärtungsgeschwindigkeiten unter Niedrigtemperatur- und Dünnfilmbeschichtungsbedingungen.

3. Anwendungen im Winter oder bei niedrigen Temperaturen

Besonders geeignet für Schnellverklebungen und Szenarien, die eine Aushärtung bei niedrigen Temperaturen erfordern.

4. Hochleistungsfähige Beschichtungen und Klebstoffe

Wird in schnell trocknenden Beschichtungen, Klebstoffen und gegossenen Kunststoffen verwendet, um die mechanischen Eigenschaften und die Haltbarkeit der Endprodukte zu verbessern.

Wichtige Produkteigenschaften und Verwendungsempfehlungen

Physikalische Eigenschaften: Nach Angaben des Lieferanten handelt es sich bei diesem Produkt um eine farblose oder blassgelbe Flüssigkeit mit einer Dichte von ca. 1,13-1,17 g/cm³ bei 25°C und einer hohen Viskosität.

Anmerkungen zur Verwendung: Es wird oft synergetisch mit Aminhärtern verwendet, um die Aushärtungsgeschwindigkeit weiter zu beschleunigen. Die Lieferanten empfehlen den Anwendern außerdem, vor der Verwendung Tests auf der Grundlage ihrer spezifischen Prozessbedingungen durchzuführen.

Beschreibung

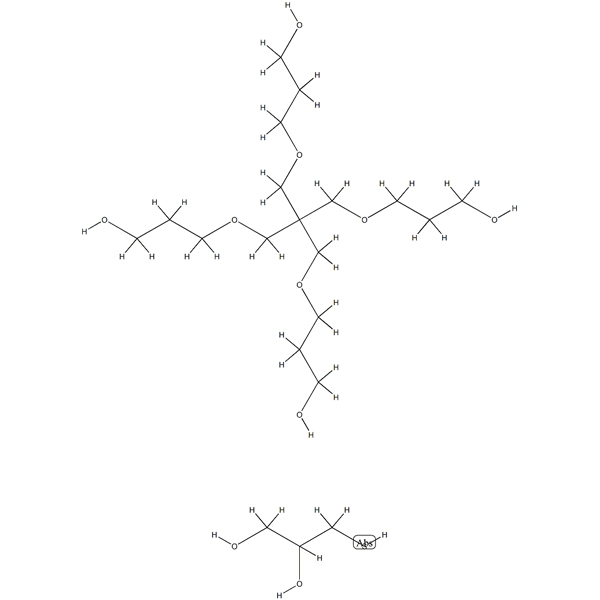

PM839 CAS 72244-98-5

| Erscheinungsbild |

Farblose transparente Flüssigkeit |

| Viskosität (25℃) , mPas |

12000~14000 |

| APHA-Farbe |

≤20 |

PM839 Verwendung:

In der Materialwissenschaft hat sich PM839 als schnelles Aushärtungsmittel für Epoxidharze bei niedrigen Temperaturen etabliert. Sein Aussehen ist rein und farblos oder eine transparente Flüssigkeit mit einem Hauch von gelblicher Farbe. Seine Viskosität liegt zwischen 12.000 und 14.000 mPa-s bei Raumtemperatur, d. h. bei 25 °C. Diese Viskositätseigenschaft macht es für eine breite Palette von Anwendungsszenarien nützlich. Sein Sulfhydrylgehalt ist mit ≥12 beeindruckend und seine Färbung wird mit ≤20 kontrolliert, was sowohl die Leistung als auch das gute Aussehen bei der Verwendung gewährleistet.

In der Praxis wird PM839 häufig in verschiedenen industriellen und elektronischen Bereichen eingesetzt. Mit dem 5-Minuten-AB-Kleber beispielsweise lassen sich in sehr kurzer Zeit effiziente Klebeergebnisse erzielen, die den Anforderungen einer schnellen Produktion entsprechen. Im Bereich der Elektronikklebstoffe bietet er eine zuverlässige Garantie für die Befestigung und Verkapselung elektronischer Komponenten. Bei der Anwendung von Epoxidharzkitt für Metalle kann er die winzigen Lücken auf der Metalloberfläche wirksam füllen und die Stabilität und Haltbarkeit der Metallstruktur verbessern. Bei der Herstellung von elektronischem Wärmeleitkleber hat PM839 nicht nur eine gute Klebeleistung, sondern kann auch eine effiziente Wärmeleitung realisieren, um die Stabilität elektronischer Geräte während des Betriebs zu gewährleisten. Im Bereich der Korrosionsschutzbeschichtungen bietet es eine starke Schutzbarriere für Metalloberflächen gegen die Erosion durch die äußere Umgebung.

Der Bereich der Siliziumstab-Schneideklebstoffe verdient besondere Erwähnung. Das Schneiden von Siliziumstäben, ein wichtiges Bindeglied in der Photovoltaik-Industrie, erfordert eine hohe Leistungsfähigkeit der Schneidklebstoffe, und der PM839 Siliziumstab-Schneideklebstoff zeigt eine ausgezeichnete Haftfestigkeit und Flexibilität nach dem Aushärten. Aus der Perspektive der historischen Entwicklung, die frühen Silizium-Stab Schneiden Klebstoff aufgrund der schlechten Leistung, was in Silizium-Stab Schneiden Prozess erscheinen oft zu fallen, Rand Chips und Risse und andere Probleme, ernsthaft beeinträchtigen die Ausbeute von Silizium-Stab Schneiden. Das Auftreten von PM839 hat diese Situation erheblich verbessert. Zum Beispiel in der Produktionslinie eines großen Photovoltaik-Unternehmens, nach der Verwendung von PM839 Schneiden Klebstoff, die Ausbeute von Silizium-Stab Schneiden von der ursprünglichen 70% auf mehr als 90%, die nicht nur die Effizienz der Produktion verbessert, sondern auch die Produktionskosten reduziert. Nach dem Schneiden der Siliziumstäbe können die mit dem Klebstoff beschichteten Siliziumscheiben durch Eintauchen in warmes Wasser schnell und einfach abgetrennt werden, was auch die industrielle Produktion in großem Maßstab erleichtert.

Die Photovoltaikindustrie befindet sich in einem goldenen Zeitalter des Wachstums, da die weltweite Nachfrage nach sauberer Energie steigt. Nach den einschlägigen Daten hat die jährliche Wachstumsrate der globalen Photovoltaik-Industrie in den letzten zehn Jahren mehr als 20% erreicht. In diesem Entwicklungstrend steigen auch die Anforderungen an das Schneiden von Siliziumstäben, was zweifellos dazu führen wird, dass die Marktnachfrage nach Klebstoff für das Schneiden von Siliziumstäben einen schnellen Wachstumstrend aufweist. Nach der Prognose von Marktforschungsinstituten, in den nächsten fünf Jahren, die Marktgröße von Silikon-Stab Schneiden Klebstoff wird erwartet, dass das doppelte Wachstum zu realisieren.

Darüber hinaus spielt PM839 auch eine wichtige Rolle im Verpackungsbereich der Elektronik- und Elektroproduktion. Als Schlüsselprozess bei der Herstellung von elektronischen und elektrischen Geräten steht die Qualität der Verpackung in direktem Zusammenhang mit der Endqualität und der Lebensdauer des Produkts. Beim Verpackungsprozess elektronischer Komponenten kommt dem Verpackungsklebstoff die wichtige Aufgabe zu, die elektronischen Komponenten zu schützen. Aus wissenschaftlicher Sicht kann er das Eindringen von Feuchtigkeit wirksam verhindern und so Kurzschlüsse oder Feuchtigkeitsschäden an elektronischen Bauteilen vermeiden. Gleichzeitig kann er auch Staub und schädliche Gase abblocken, um zu verhindern, dass diese Verunreinigungen elektronische Geräte oder Leiterplatten korrodieren. In einigen Elektronikunternehmen in Küstenregionen beispielsweise ist die Ausfallrate elektronischer Bauteile aufgrund der hohen Luftfeuchtigkeit deutlich höher, wenn keine hochwertigen Verpackungsklebstoffe verwendet werden. Darüber hinaus können Verpackungsklebstoffe die Auswirkungen von äußeren Kräften und Vibrationen auf elektronische Bauteile durch ihre eigene Dämpfungswirkung verlangsamen oder ausgleichen und so die Stabilität elektronischer Geräte erheblich verbessern. Da die Nachfrage nach Smartphones, Smart Homes und anderen elektronischen und elektrischen Produkten weltweit weiter steigt, wächst auch der Markt in China, dem weltweit größten Markt für die Produktion und den Verbrauch von Elektronik. Statistiken zufolge ist der chinesische Elektronikmarkt in den letzten fünf Jahren mit einer jährlichen Rate von etwa 15% gewachsen, was die stetig wachsende Nachfrage nach Klebstoffen für elektrische und elektronische Produkte weiter antreiben wird.

PM839 Paket

25 kg/Fass oder 220 kg/Fass

PM839 Lagerung:

Sie werden in einem trockenen, sauberen Lager mit guter Belüftung aufbewahrt.

Vermeiden Sie Licht- und Hitzeeinwirkung.

Schutz des Produkts vor Auslaufen, Regen und Sonneneinstrahlung während des Transports.

Kontaktieren Sie uns jetzt!

Wenn Sie eine Preis- und Musterprüfung benötigen, tragen Sie bitte Ihre Kontaktdaten in das unten stehende Formular ein. Wir werden uns in der Regel innerhalb von 24 Stunden mit Ihnen in Verbindung setzen. Sie können mir auch eine E-Mail schicken info@longchangchemical.com während der Geschäftszeiten ( 8:30 bis 18:00 Uhr UTC+8 Mo.~Sa. ) oder nutzen Sie den Live-Chat auf der Website, um eine schnelle Antwort zu erhalten.

Xavier Thompson -

Eine wunderbare Erfahrung! Der Service war erstklassig, die Produktqualität hat meine Erwartungen übertroffen.