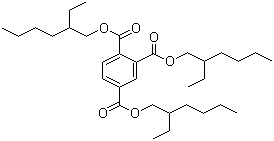

Trioctyl trimellitate Application scenarios

1. Wires and Cables

105°C-rated heat-resistant insulation material for wires and cables (core application)

Excellent high-temperature stability, low volatility, superior electrical insulation (high volume resistivity)

2. Automotive Industry

Automotive interior components (e.g., instrument panels), in-vehicle cable insulation

High-temperature resistance, durable, suitable for automotive environments

3. Seals and Sheets

Heat-resistant gaskets, sheets, and films Oil and water extraction resistance, dimensional stability, low migration

4. Other Plastic Products

Suitable for polyvinyl chloride (PVC), vinyl copolymers, nitrocellulose, polymethyl methacrylate (PMMA), etc. Excellent compatibility with various resins, enhances material flexibility and durability

💡 Comparison with Other Plasticizers

In practical applications, TOTM typically serves as a high-performance alternative, exhibiting distinct characteristics from common plasticizers:

Compared to phthalates (e.g., DOP): TOTM features lower volatility, superior high-temperature resistance, and enhanced migration resistance, resulting in extended service life—particularly suited for high-temperature environments.

Compared to polymeric plasticizers: TOTM maintains good heat resistance while offering superior processability, low-temperature flexibility, and resin compatibility.

William Thompson –

Superb service, rapid responses, smooth logistics, enjoyable shopping!