NPGDA Monomer Application scenarios

1. Kaplamalar

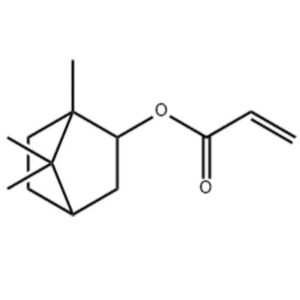

Radiation-curable coatings for wood, plastic, and metal surfaces enhance the film’s abrasion resistance, scratch resistance, and chemical resistance.

2. Ink

Used in light-curable inks, such as flexible printed materials, providing rapid drying speed and excellent adhesion.

3. Adhesive

Serves as a component in UV-curable adhesives for applications requiring fast bonding.

4. Graphic Arts and Printing Plates

One of the key raw materials for manufacturing photosensitive resin printing plates (e.g., photopolymer plates).

5. Elektronik

Used in producing electronic chemicals like photoresists, solder masks, and encapsulation materials.

6. Diğer Uygulamalar

Serves as a crosslinking aid in synthetic rubber vulcanization and PVC wire radiation crosslinking. Also used in preparing biomedical materials such as dental composites and hydrogels.

💡 Properties and Advantages

NPGDA’s widespread application stems primarily from the following characteristics:

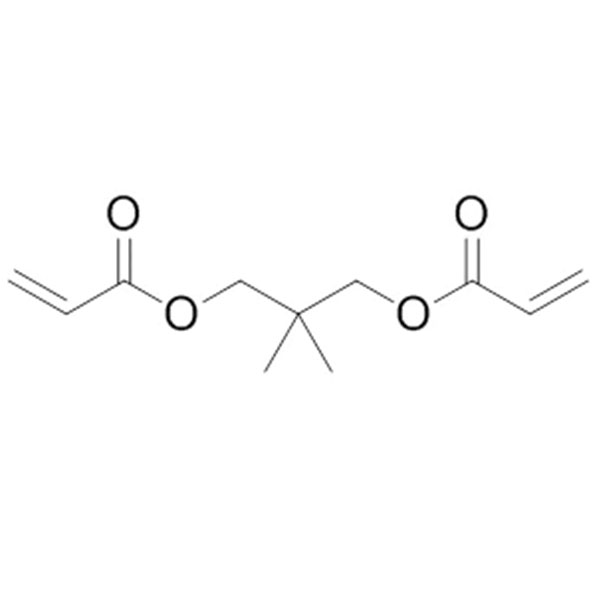

High Reactivity and Rapid Curing: Containing two acrylic double bonds, it undergoes rapid polymerization under UV or electron beam irradiation, forming a crosslinked network structure.

Excellent Final Properties: Its chemical structure imparts cured coatings or materials with superior abrasion resistance, chemical resistance, scratch resistance, and high hardness.

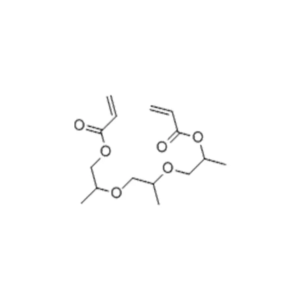

Excellent Dilution Capability: As a low-viscosity liquid, it effectively reduces the viscosity of resin systems, improving processability. It participates in the reaction itself, becoming part of the cured film without volatilizing.

To reduce skin irritation, modified products (such as propoxylated NPGDA) are also available industrially. These maintain high performance while offering lower irritation.

Evelyn Carpenter -

Olağanüstü hizmet! Ürünün kalitesi beklentilerimi aştı ve teslimat inanılmaz derecede hızlıydı. Son derece memnun kaldım!