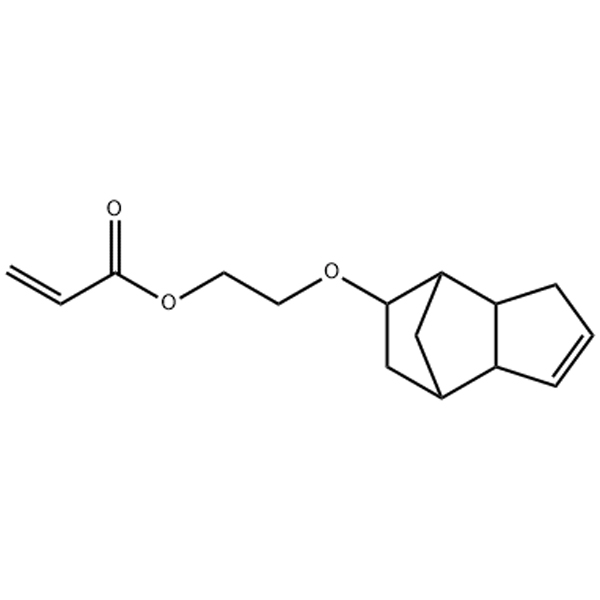

DCPEOA Monomer Application scenarios

1. UV/EB Light-Curing Systems

High-performance coatings (wood, metal, plastic), flexible electronic encapsulation adhesives, 3D printing photopolymer resins, etc.

As an active diluent, it adjusts viscosity and participates in the curing reaction. Its structure enhances coating heat resistance, adhesion, and scratch resistance.

2. Adhesives and Pressure-Sensitive Adhesives

Electrolyte-resistant reinforced acrylic pressure-sensitive adhesives, fast-curing acrylic structural adhesives, composite toughening agents, etc.

Enhances bonding strength to substrates like metals and plastics while providing excellent resistance to high temperatures, humid heat aging, and chemical solvents.

3. Composite Materials & Plastic Modification

Modified EVA foam footwear materials, resin toughening modifications.

Introduces rigid structures via copolymerization to enhance mechanical properties (e.g., impact resistance) and heat deflection temperature.

4. Specialty Chemicals & Additives

Heavy metal scavengers for refining processes, reinforcing emulsions for papermaking.

Their unique structure serves as a functional component for synthesizing additives with specific chemical functions, such as capturing metal ions or enhancing paper properties.

5. Civil Engineering and Construction

Low-odor sprayable resin coatings for roads and buildings.

As a high-boiling-point reactive monomer, it effectively reduces resin system odors during application while improving coating performance.

Yorumlar

Henüz yorum yok.