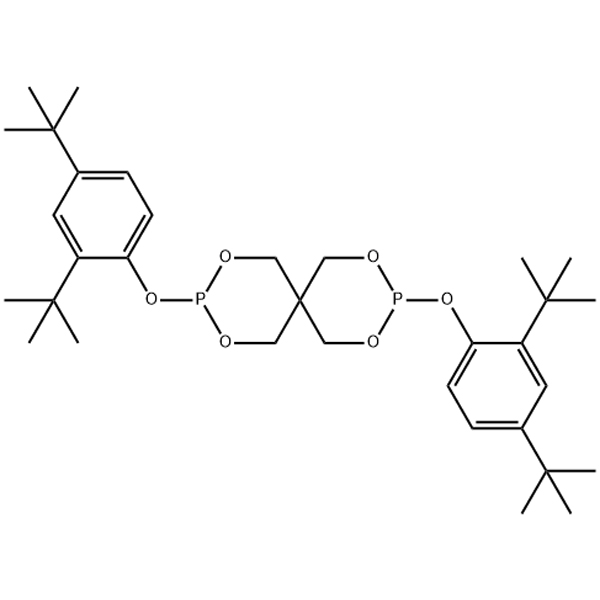

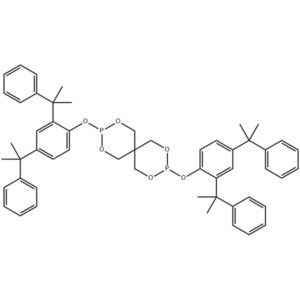

Antioxidant 626 Application scenarios

1. General-Purpose Plastics

Polyethylene (PE), Polypropylene (PP), Ethylene-vinyl acetate copolymer (EVA)

Prevents thermal degradation and discoloration during processing such as film blowing, injection molding, and extrusion, extending product lifespan.

2. Engineering Plastics

Polystyrene and its copolymers, Polyamide (PA), Polycarbonate (PC), ABS, Polyurethane (PU)

Protects materials, ensuring stable performance under high temperature and high shear processing conditions, preventing molecular weight changes and yellowing.

3. Other Materials

Elastomers, Adhesives, Rubber, Coatings

Improves the stability of materials during processing and use.

🔬 Functional Principle and Usage

Temel İşlev: It is a “secondary antioxidant,” primarily working by decomposing hydroperoxides generated during polymer processing, thereby preventing chain reactions that lead to material aging. This effectively prevents thermal oxidative degradation, discoloration (yellowing), and molecular chain scission during processing.

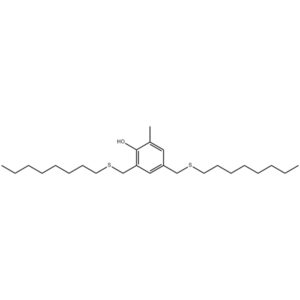

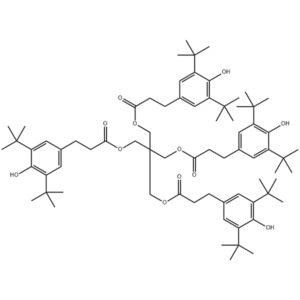

Synergistic Use: It is usually not used alone, but rather compounded with “primary antioxidants” (such as hindered phenol-based IRGANOX series or antioxidant AT-10, etc.) to produce a significant synergistic effect, providing more comprehensive and long-lasting stable protection.

Nathan Rivers -

Üstün hizmet, hızlı yanıtlar, verimli lojistik, keyifli alışveriş!