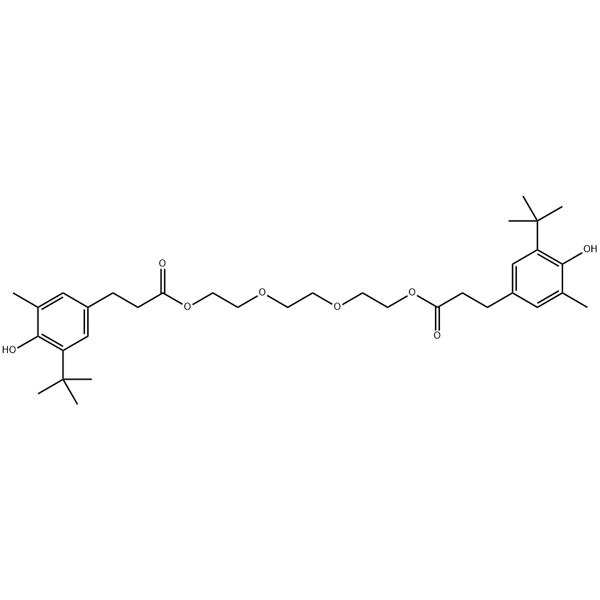

Antioxidant 245 Application scenarios

1. Styrenic Polymers

High-impact polystyrene (HIPS), ABS, AS, MBS resins, etc.

Provides excellent processing and long-term thermal stability, preventing material yellowing and embrittlement.

2. Engineering Plastics

Polyoxymethylene (POM, homopolymer/copolymer), polyamide (PA, nylon), thermoplastic polyesters (such as PET, PBT)

Protects material performance during high-temperature processing and use; a commonly used stabilizer for POM.

3. Polyurethane (PU)

Spandex, other polyurethane elastomers and foams

Prevents thermal oxidative degradation of polyurethane, maintaining its elasticity and physical properties.

4. Polyvinyl Chloride (PVC)

PVC resins and products

Acts as an effective chain terminator during PVC polymerization; provides thermal stabilization in finished products.

5. Rubber and Elastomers

Styrene-butadiene rubber (SBR) and its latex, hydroxylated styrene-butadiene rubber, other elastomers

Prevents rubber aging and improves mechanical properties (such as tensile strength and elongation at break).

6. Other Fields

Adhesives, synthetic fibers, lubricants, coatings, and food contact packaging materials, etc.

Provides antioxidant protection in the corresponding systems; in food packaging that meets regulatory requirements, it prevents oxidation of oils and other components.

💡 Technical Features and Usage

Non-polluting: Usually a white powder, it does not easily color the product, making it suitable for products with high color requirements.

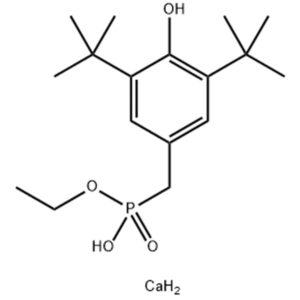

Combined use: Often used in combination with auxiliary antioxidants (such as thioethers, phosphites) or light stabilizers to produce better synergistic stabilization effects.

Isla Bennett -

Olağanüstü hizmet ve ürün! Ürün derhal geldi ve tam olarak tarif edildiği gibiydi. Kesinlikle geri dönen bir müşteri olacak!