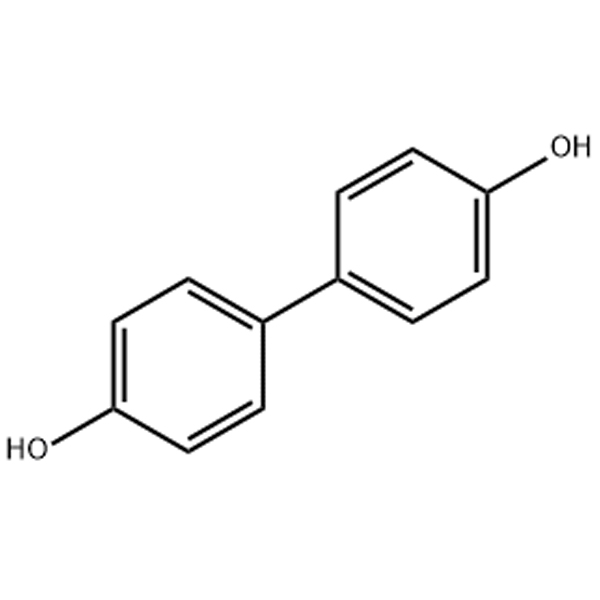

Antioxidant 4,4′-biphenol Application scenarios

1. Antioxidants for Polymer Materials (Plastics and Rubber)

This is its core application area. It is often used as a primary antioxidant or in combination with secondary antioxidants to provide a synergistic effect.

Engineering Plastics

Polycarbonate: This is one of its most important applications. During the synthesis and processing of PC, 4,4′-biphenyl effectively prevents yellowing and molecular weight reduction caused by thermal oxidation, maintaining the high transparency and mechanical properties of PC.

Polyamide: In polyamide resins such as nylon, it provides good long-term thermal stability and color stability.

Polyester: Such as PBT and PET, used to improve their antioxidant capacity during processing and use.

General-Purpose Plastics: Can be used in modified materials such as ABS and HIPS where high heat resistance is required.

Elastomers: In synthetic rubbers such as SBR and BR, it acts as an antioxidant to extend the service life of products, especially in high-temperature environments.

2. Polyurethane Industry

Used as an antioxidant stabilizer in polyurethane elastomers and foams to prevent embrittlement, discoloration, and performance degradation due to oxidation during preparation and subsequent use.

3. As a Key Chemical Intermediate

It is also an important chemical intermediate used in the synthesis of other more complex compounds.

Synthesis of High-Performance Polymer Monomers: It is one of the key monomers for the preparation of biphenyl-type epoxy resins, polyesters, and polyarylates, among other high-performance engineering plastics.

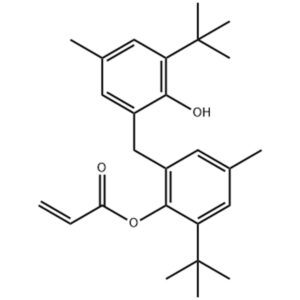

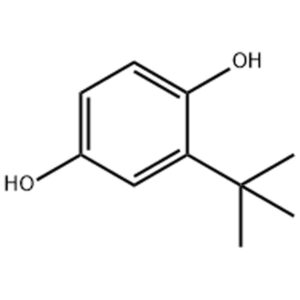

Synthesis of Other Additives: It can be used to synthesize UV absorbers, higher molecular weight phenolic antioxidants, etc.

4. Diğer Özel Uygulamalar

Liquid Crystal Materials: Due to its rigid biphenyl structure and symmetry, it can be used as an intermediate in the synthesis of certain liquid crystal compounds.

Oil Additives: It can be used as an antioxidant additive in high-end synthetic lubricants or specialty greases, but its application scale in this area is smaller than that in polymer materials.

Key Performance Characteristics (Why it is chosen in these scenarios)

Highly Effective Antioxidant Properties: The bisphenol hydroxyl structure provides strong free radical scavenging capabilities.

Excellent heat resistance: Good thermal stability; does not easily volatilize or decompose during high-temperature processing (e.g., PC processing temperatures can reach 300°C).

Good color stability: Effectively inhibits yellowing caused by oxidation, which is crucial for transparent and light-colored products.

Low volatility: Relatively high molecular weight; does not easily migrate or evaporate during processing and use.

Diana K -

Olağanüstü bir deneyim! Ürün beklentilerimi aştı ve müşteri hizmetleri birinci sınıftı. Yıldırım hızında teslimat da! ⭐⭐⭐⭐⭐