Description

Chemical Name.

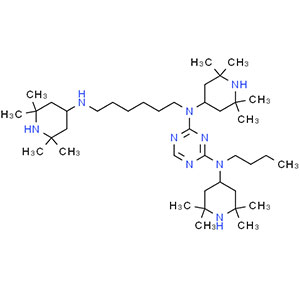

Polymer of the reaction product of N,N’-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,6-hexanediamine with 2,4,6-trichloro-1,3,5-triazine and N-butyl-1-butylamine and N-butyl-2,2.6,6-tetramethyl-4-piperidinamine

CAS No.:192268-64-7

Appearance:White or light yellow granule

Melting point range:120-135°C

Characteristics and application

Characteristics:High molecular weight hindered amine light stabilizer with excellent long-lasting light and heat stability, as well as excellent color protection, narrow molecular weight distribution, showing excellent processability during material processing, in addition, it also has unique long-lasting heat stability for filled PP products and carbon black filling system.

Applications: The product is suitable for polyolefin materials, PP fibers, narrow tapes, thin and thick PP and PE products with long service life, especially for outdoor products that require efficient long term thermo-oxidative stability and efficient light stability, as well as PP and carbon black filled systems.

Advantages

- High Efficiency: Provides long-term UV and thermal oxidation protection.

- Compatibility: Compatible with various polymers and additives.

- Eco-Friendliness: Low toxicity, meets environmental requirements.

- Heat Resistance: Stable performance under high temperatures.

Usage Recommendations

- Dosage:

- Typical dosage is 0.1% to 0.5% of the polymer weight, depending on the application and material type.

- Processing Temperature:

- Suitable for conventional processing temperatures but should not exceed its thermal decomposition temperature (usually above 250°C).

- Combination with Other Additives:

- Can be used with antioxidants, UV absorbers, and other additives for comprehensive protection.

Precautions

- Store in a cool, dry place away from high temperatures and moisture.

- Use protective equipment to avoid direct contact with skin and eyes.

Light Stabilizer 2020 is a versatile light stabilizer that significantly enhances the weatherability and service life of materials, making it widely used in industries requiring UV and thermal oxidation protection.

Contact Us Now!

If you need COA, MSDS or TDS, please fill in your contact information in the form below, we will usually contact you within 24 hours. You could also email me info@longchangchemical.com during working hours ( 8:30 am to 6:00 pm UTC+8 Mon.~Sat. ) or use the website live chat to get prompt reply.