Antioxidant TNPP Application scenarios

1. Plastics (PVC, polyolefins, etc.)

Prevents thermal oxidative degradation, maintains color, and improves processing performance. A key heat stabilizer in PVC processing.

2. Synthetisch rubber en elastomeren

As a non-polluting antioxidant, prevents aging and is suitable for light-colored products.

In US patents, it is used in combination with amine antioxidants in products such as tires.

3. Engineering Plastics (ABS, polyester, etc.)

Provides thermal stability and prevents discoloration during high-temperature processing.

It has a synergistic effect when used with phenolic antioxidants.

4. Coatings en inkten

As an additive, it prevents oxidative deterioration during storage and use.

5. Other Polymer Materials

Used in epoxy resins, polyamides, etc., to prevent oxidative degradation and improve viscosity.

For example, in nylon flame-retardant composites, it prevents molecular weight reduction.

🔬 Core Mechanism of Action

TNPP achieves the aforementioned effects primarily through the following mechanisms:

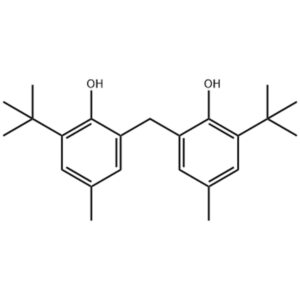

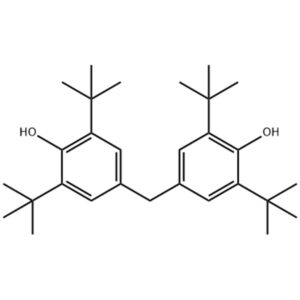

Als secundaire antioxidant: It efficiently decomposes hydroperoxides produced during polymer oxidation, thereby preventing chain reactions. It is often used in combination with primary antioxidants (such as phenols) for even better results.

As a metal ion chelating agent: It can chelate trace metal ions (such as catalyst residues) that may be present in the material, preventing these ions from catalyzing oxidation reactions.

As a processing stabilizer: During high-temperature processing, it effectively prevents polymer melt degradation, helps reduce melt viscosity, and facilitates smoother processing.

Alexander Riet -

Uitzonderlijke service, snelle antwoorden, efficiënte logistiek, heerlijk winkelen!