Antioxidant PEP-36 Toepassingsscenario's

1. Polyolefinen

Polypropyleen (PP), polyethyleen met hoge dichtheid (HDPE), enz.

Biedt verwerkingsstabiliteit, vermindert verkleuring en veranderingen in de smeltstroom bij hoge temperaturen.

2. Styreenharsen

Polystyreen (PS), ABS-hars, enz.

Behoudt kleurstabiliteit tijdens verwerking en voorkomt materiaaldegradatie.

3. Technische kunststoffen

Polyamide (PA), polycarbonaat (PC), gemodificeerd polyfenyleenether (m-PPE), polyester, enz.

Voldoet aan de vereisten voor verwerking bij hoge temperaturen, behoudt de materiaaleigenschappen en voorkomt verkleuring.

4. Overige/specialistische materialen

PEEK (polyetheretherketon), enz.

Voorziet in de behoefte aan weerstand tegen degradatie bij hoge temperaturen in speciale materialen (verwante producten zijn in ontwikkeling).

Belangrijkste kenmerken en gebruiksaanwijzingen

Naast het brede scala aan toepassingen, zal het begrijpen van de volgende kenmerken helpen bij een beter gebruik:

Geschikt voor verwerking bij hoge temperaturen: De hoge hittebestendigheid en hydrolysebestendigheid maken het bijzonder geschikt voor toepassingen waarbij verwerking bij hoge temperaturen vereist is of waarbij strenge kleurvereisten gelden.

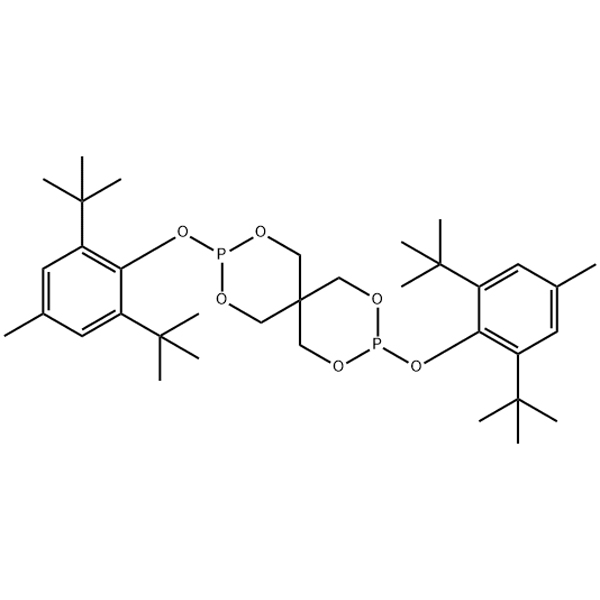

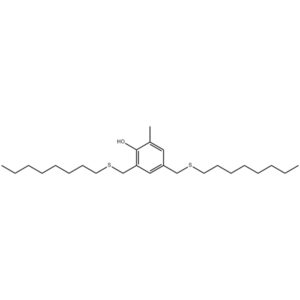

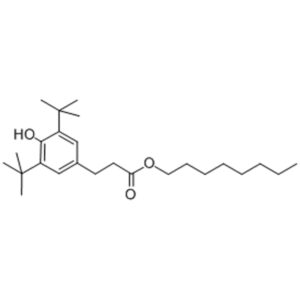

Synergetisch effect: Wanneer het gebruikt wordt in combinatie met fenolhoudende antioxidanten (zoals antioxidant 1010), heeft het een aanzienlijk synergetisch effect en biedt het een uitgebreidere en langdurige stabiele bescherming voor het polymeer.

Naleving voedselcontact: Dit additief is goedgekeurd voor gebruik in materialen die met levensmiddelen in aanraking komen in de Verenigde Staten, de Europese Unie en China (GB 9685-2016). Het maximale gebruik in polyethyleen is bijvoorbeeld 0,25%.

Opslag en veiligheid: Het product moet op een koele, droge plaats worden bewaard en onmiddellijk na opening worden gebruikt, omdat het in een vochtige omgeving kan hydrolyseren. Vermijd het inademen van stof tijdens het hanteren en wees bewust van de mogelijke invloed op het aquatisch milieu.

Jack Thompson -

Uitstekende service, snelle antwoorden, efficiënte logistiek, fantastisch winkelen!